Electric horn driving circuit of electric vehicle

A technology for driving circuits and electric horns, applied in vehicle parts, bicycle accessories, audio signals, etc., can solve the problem of difficult to adjust the sound of the horn, and achieve the effect of adjusting the sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further explained below in conjunction with the accompanying drawings.

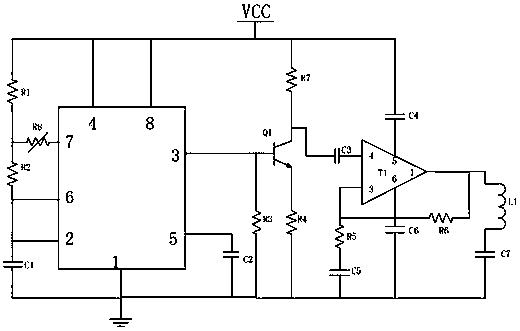

[0008] Such as figure 1 As shown, an electric car horn driving circuit includes resistors R1-R7, variable resistors R8, capacitors C1-C7, inductor L1, transistor Q1, amplifier T1 and a 555 timer chip. Amplifier T1 chooses the feedback amplifier of model AD8065, its common-mode rejection ratio can reach -100dB, and the output voltage can reach up to 24V.

[0009] The fourth and eighth pins of the 555 timer chip are connected to the power supply VCC, and the seventh pin of the 555 timer chip is connected to the power supply VCC through the series branch of the variable resistor R8 and the resistor R1. The second and sixth pins of the 555 timer chip are also connected to one end of the capacitor C1 and the resistor R2 at the same time, the other end of the capacitor C1 is grounded, and the other end of the resistor R2 is connected to the common end of the variable resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com