Automatic slitter

An automatic slitting machine and slitting machine technology, which is applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of inability to perform calibration, low cutting efficiency, and difficulty in meeting the needs of production and processing, etc. Achieve the effect of high precision and automation, high automation, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

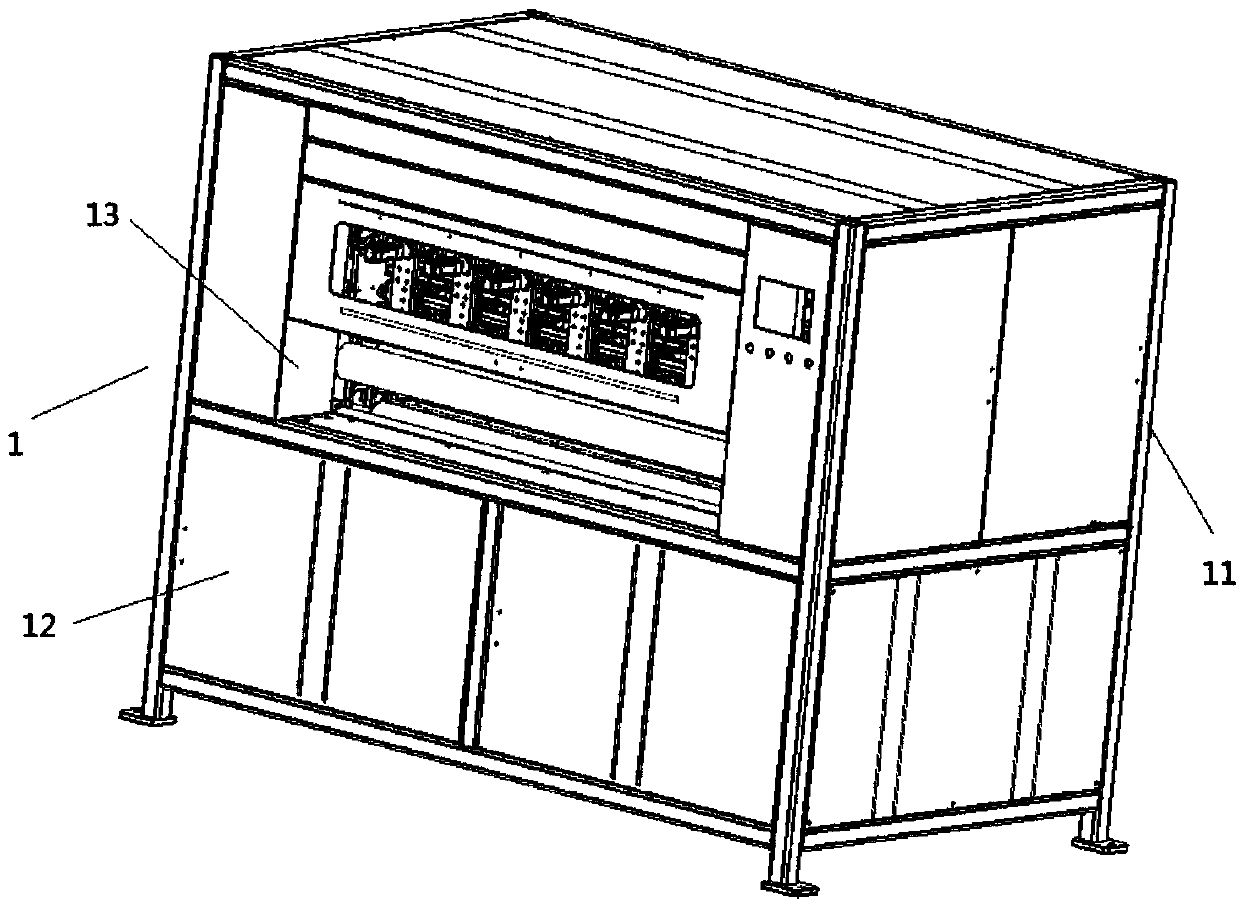

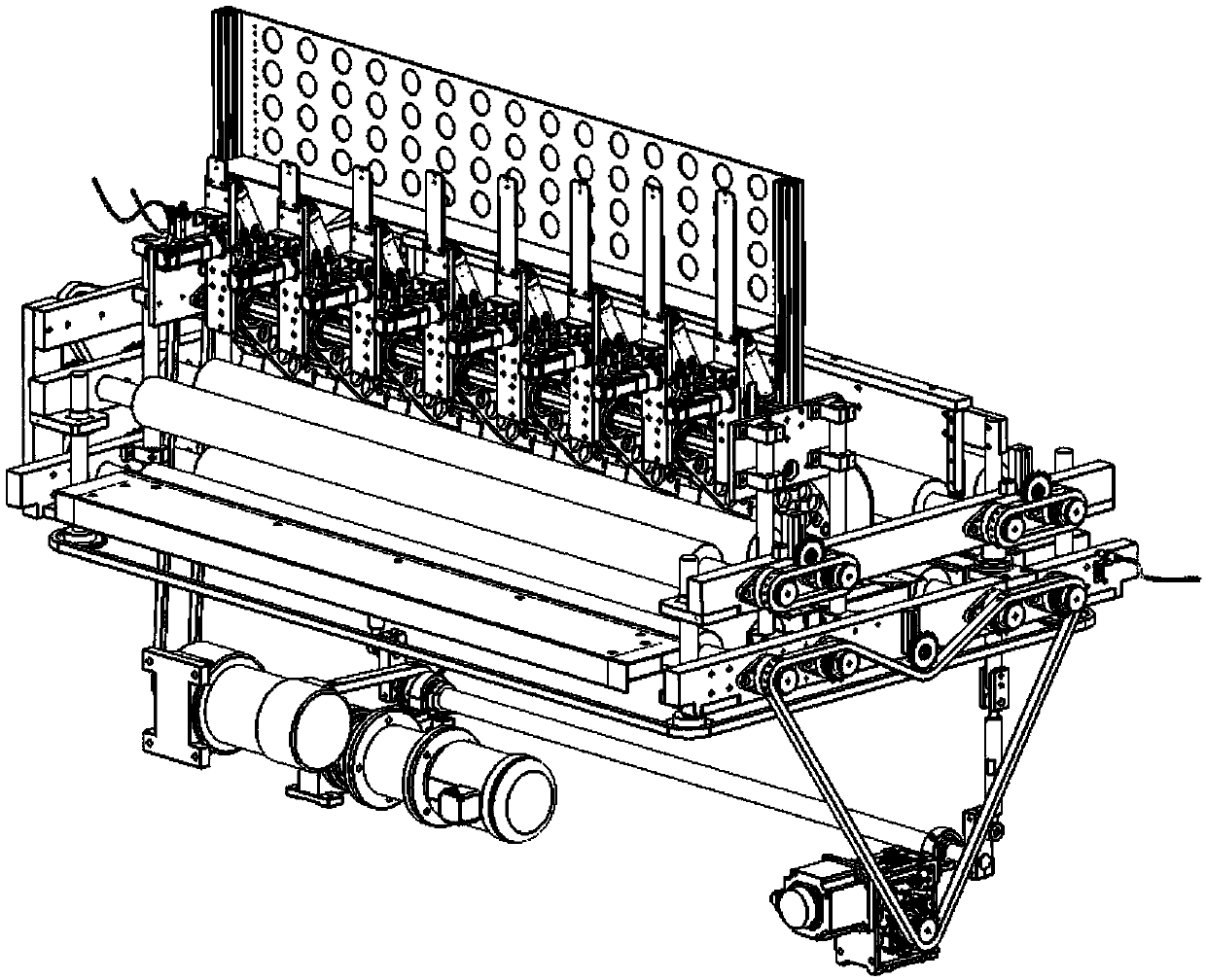

[0035] See figure 1 , an automatic slitting machine of the present invention, including a casing 1 and a cutting mechanism and a feeding mechanism arranged inside the casing 1; wherein, the casing 1 includes a frame 11 and a plurality of door panels installed on the frame 11 12. The front surface and the rear surface of the casing 1 are respectively provided with feeding windows 13 for materials to enter and exit.

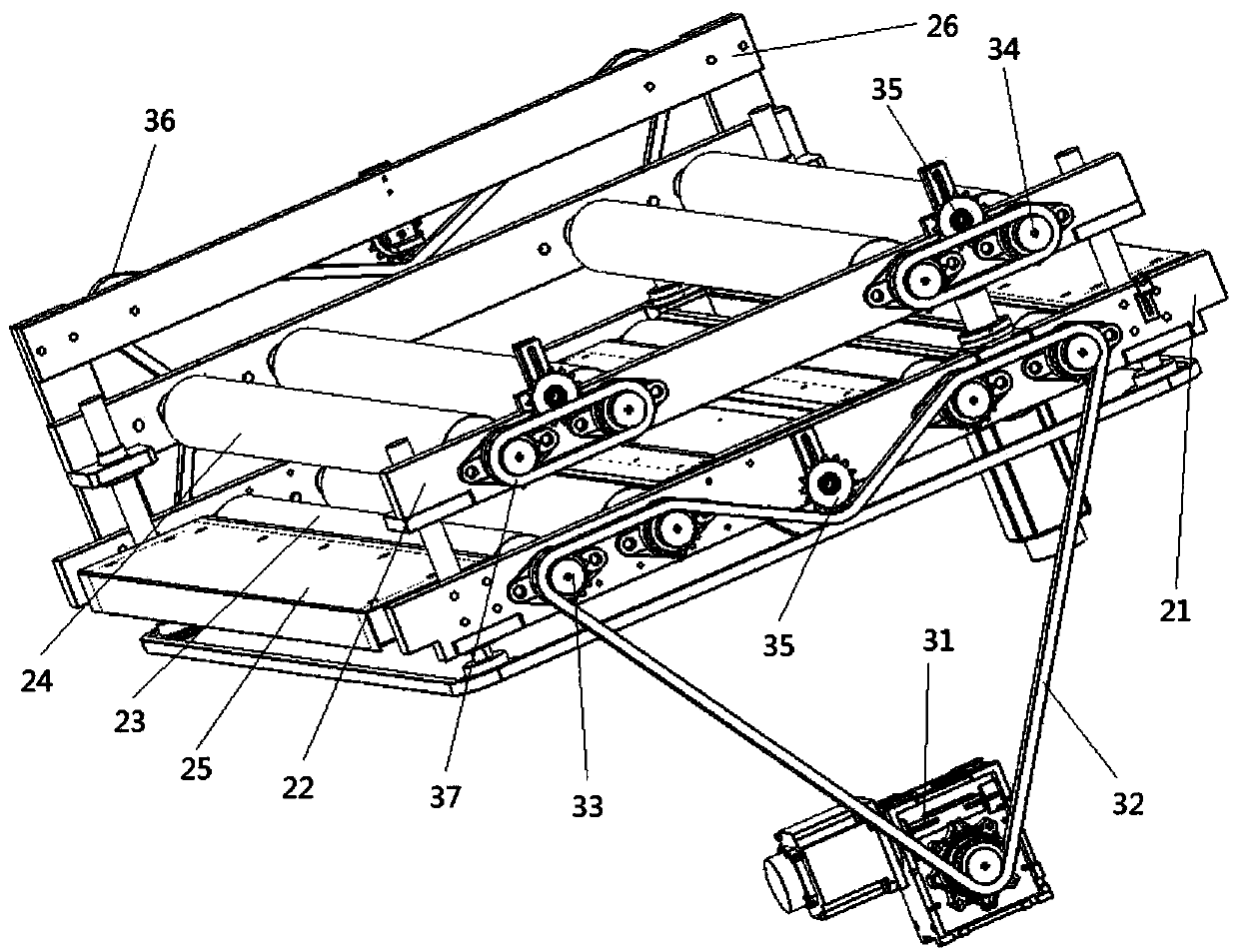

[0036] See Figure 2-3 , the feeding mechanism includes a first driver, a pair of upper roller fixing plates 22 and a pair of lower roller fixing plates 21 fixed on the frame 11, and the two ends are respectively connected to the upper feeding roller group 24 between the upper roller fixing plates 22 , and the two ends are respectively rotatably connected to the lower feeding roller group 23 between the lower roller fixing plates 21.

[0037] See Figure 4 , the upper feeding roller group 24 and the lower feeding roller group 23 all include two pairs of feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com