Safe and efficient steel ladle side-blown spraying powder refining device and method

A powder supply device and powder spraying technology, which is applied in the field of steelmaking, can solve problems such as the blockage of bottom blowing holes and the maintenance difficulty of bottom blowing powder spraying components, and achieve the effects of easy maintenance, shortened refining treatment time, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

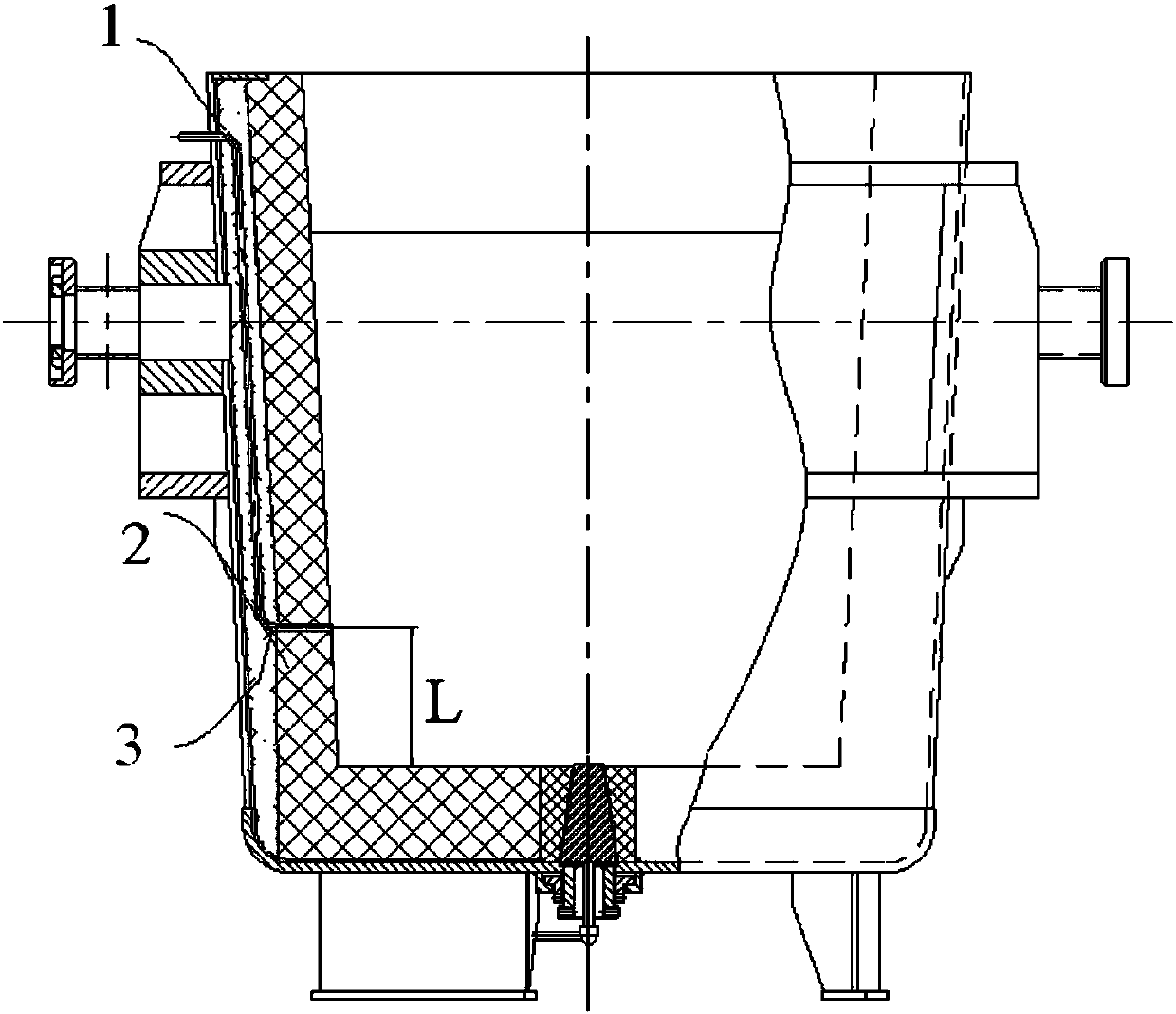

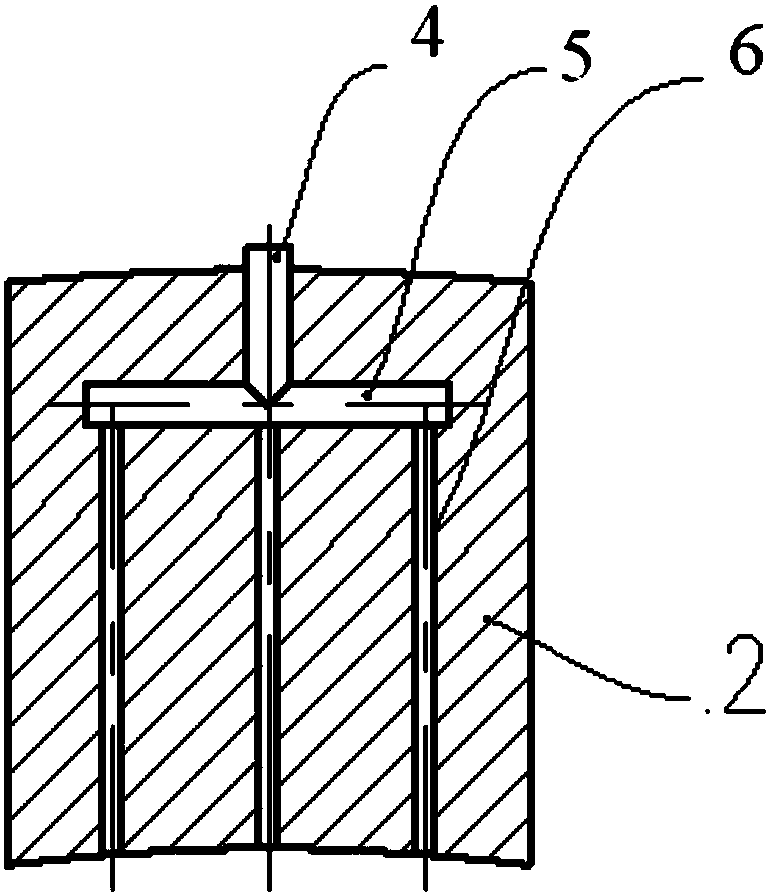

[0047] Present embodiment is aimed at 150t ladle, adopts the device of safe, efficient ladle side-blown powder injection refining to spray powder in ladle, as figure 1 As shown, a lining brick 2 is built inside the cladding shell 1 of the ladle, and a lining brick embedded with a steel pipe with an air chamber at a distance of 800 mm from the bottom L of the ladle is used as a powder supply device. One end of the powder supply device is connected to the cladding The outside of the shell 1 is connected through the powder supply channel 3, and the powder is blown from the outside of the shell 1 to the inside of the lining brick 2 to supply powder to the inside of the ladle; it is worth noting that the powder supply channel 3 passes between the shell 1 and the lining brick 2 The gap in the cladding 1 passes through, and the position where the powder supply channel 3 passes through the cladding 1 is located on the top of the cladding 1, and its position is higher than the upper sur...

Embodiment 2

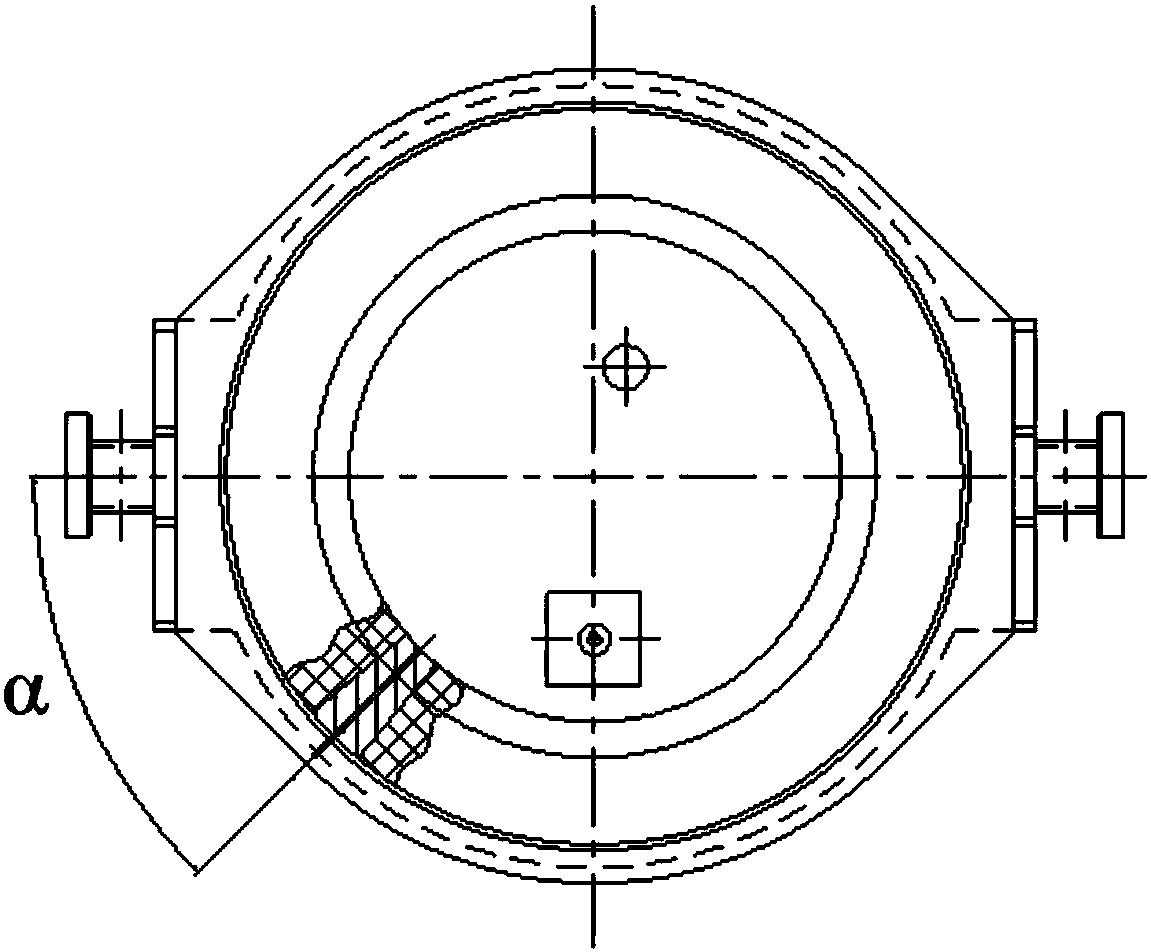

[0058] Present embodiment is aimed at 150t ladle, adopts the device of safe, efficient ladle side-blown powder injection refining to spray powder in ladle, as Figure 4 As shown, a lining brick 2 is built inside the cladding shell 1 of the ladle, and 2 lining bricks embedded with a steel pipe with an air chamber at a distance of 800 mm from the bottom L of the ladle are used as powder supply devices to supply air to the inside of the ladle respectively; The two powder supply devices have the same structure, that is, one end of the powder supply device is connected to the outside of the shell 1 through the powder supply channel 3, and the powder is blown from the outside of the shell 1 to the inside of the lining brick 2 to supply powder to the inside of the ladle; it is worth noting Yes, the powder supply passage 3 passes through the cladding 1 through the gap between the cladding 1 and the lining brick 2, and the position where the powder supply passage 3 passes out of the cla...

Embodiment 3

[0070] Present embodiment is aimed at 150t ladle, adopts the device of safe, efficient ladle side-blown powder injection refining to spray powder in ladle, as Figure 7 As shown, a lining brick 2 is built inside the cladding shell 1 of the ladle, and 3 lining bricks embedded with a steel pipe with an air chamber at a distance of 800 mm from the bottom L of the ladle are used as powder supply devices to supply air to the inside of the ladle respectively; The three powder supply devices have the same structure, that is, one end of the powder supply device is connected to the outside of the shell 1 through the powder supply channel 3, and the powder is blown from the outside of the shell 1 to the inside of the lining brick 2 to supply powder to the inside of the ladle; it is worth noting Yes, the powder supply passage 3 passes through the cladding 1 through the gap between the cladding 1 and the lining brick 2, and the position where the powder supply passage 3 passes out of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com