Automatic asphalt sampling device

An automatic sampling device and asphalt technology, which is applied in sampling devices, sampling, measuring devices, etc., can solve problems such as affecting the accuracy of sample retention detection, changes in sample retention performance, and inability to take samples.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

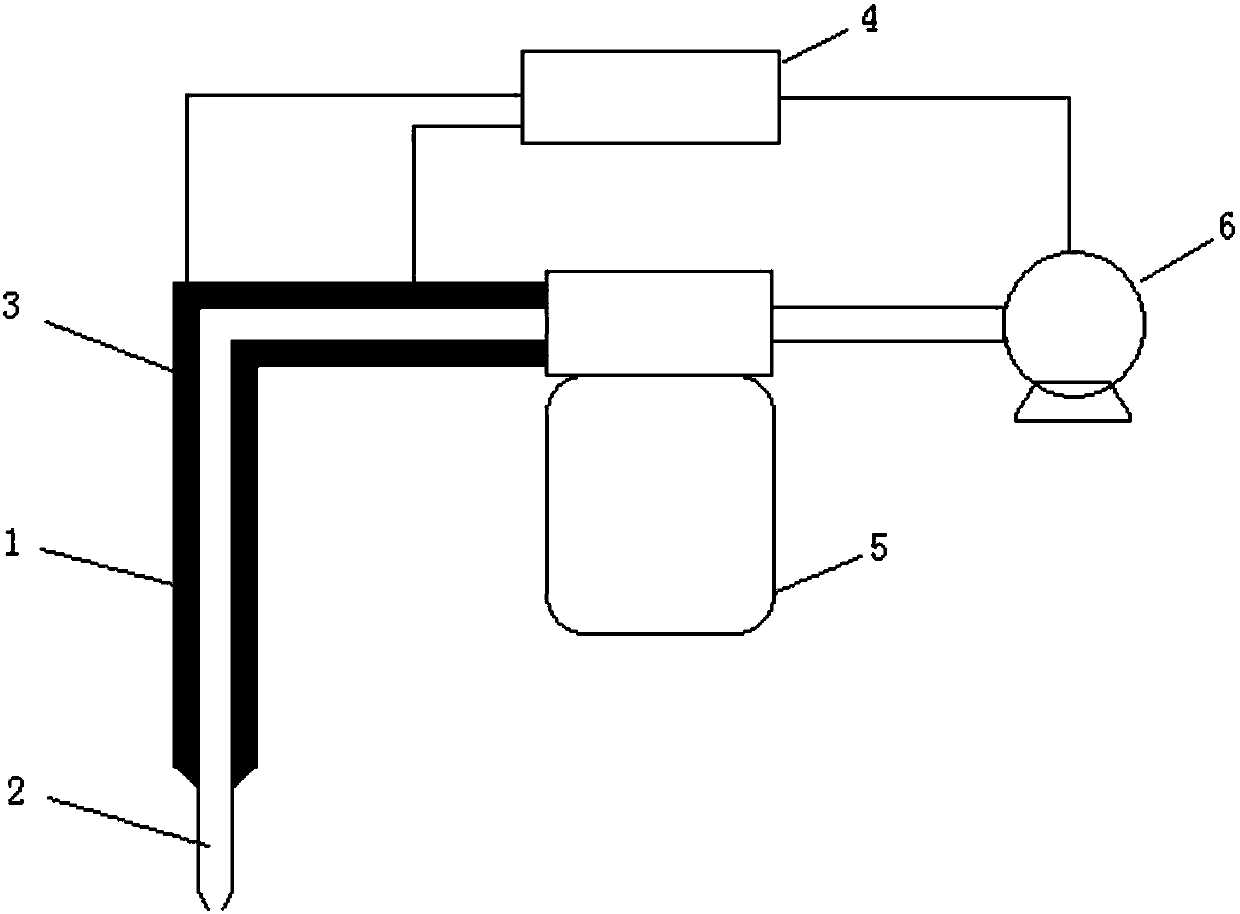

[0020] see figure 1 , an asphalt automatic sampling device provided in the embodiment of the present invention, such as figure 1 As shown, the device includes a heating sleeve 1, an asphalt sampling pipe 2, a temperature sensor 3, a temperature control assembly 4, a negative pressure sampling bottle 5, and a vacuum pump 6; the heating sleeve 1 is set outside the asphalt sampling pipe 2, The temperature sensor 3 is connected to the heating sleeve 1, the negative pressure sampling bottle 5 is connected to the asphalt sampling pipe 2, the vacuum pump 6 is connected to the negative pressure sampling bottle 5, and the temperature control assembly 4 Connected with the heating jacket 1 and the vacuum pump 6;

[0021] Wherein, the temperature control assembly 4 is used to control the heating temperature of the heating sleeve 1, the heating sleeve 1 is used to heat the asphalt sampling pipe 2, and the temperature sensor 3 is used to detect the asphalt The current temperature of the s...

Embodiment approach

[0024] The usage method of the device provided by the present application is described in detail below by having the mode of use: when the device is in specific use, a 30g sample is taken from a 1 liter volume of asphalt sample, and placed in a sampling bottle for use in asphalt testing. combine figure 1 The description of each component in the structural schematic diagram describes the specific implementation, as follows:

[0025] Step 1: From figure 1 The 4 temperature control devices of the asphalt automatic sampling device set the temperature of the 1 asphalt sampling pipe to 120°C, and start the heating function. The temperature of the asphalt sampling pipe rises, and the temperature control device reads the current temperature of the asphalt sampling pipe through the 3 temperature sensors. When the temperature reaches the set Temperature value, you can start sampling;

[0026] Step 2: Place the bitumen sampling tube at the bitumen sampling site, and observe the depth o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com