Multilayer ceramic capacitor

A technology of ceramic capacitors and capacitors, which is applied in the direction of laminated capacitors, capacitors, fixed capacitors, etc., can solve the problems of reduced capacitance and difficulty in obtaining heat dissipation, and achieve excellent heat dissipation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 》

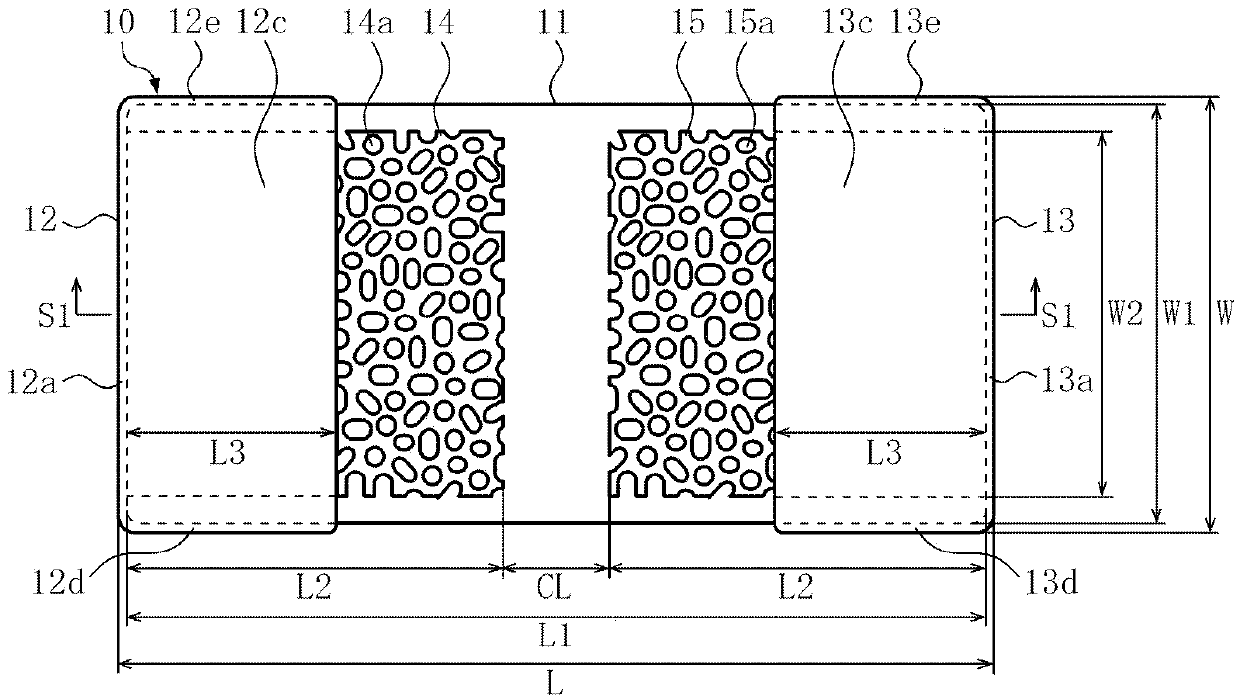

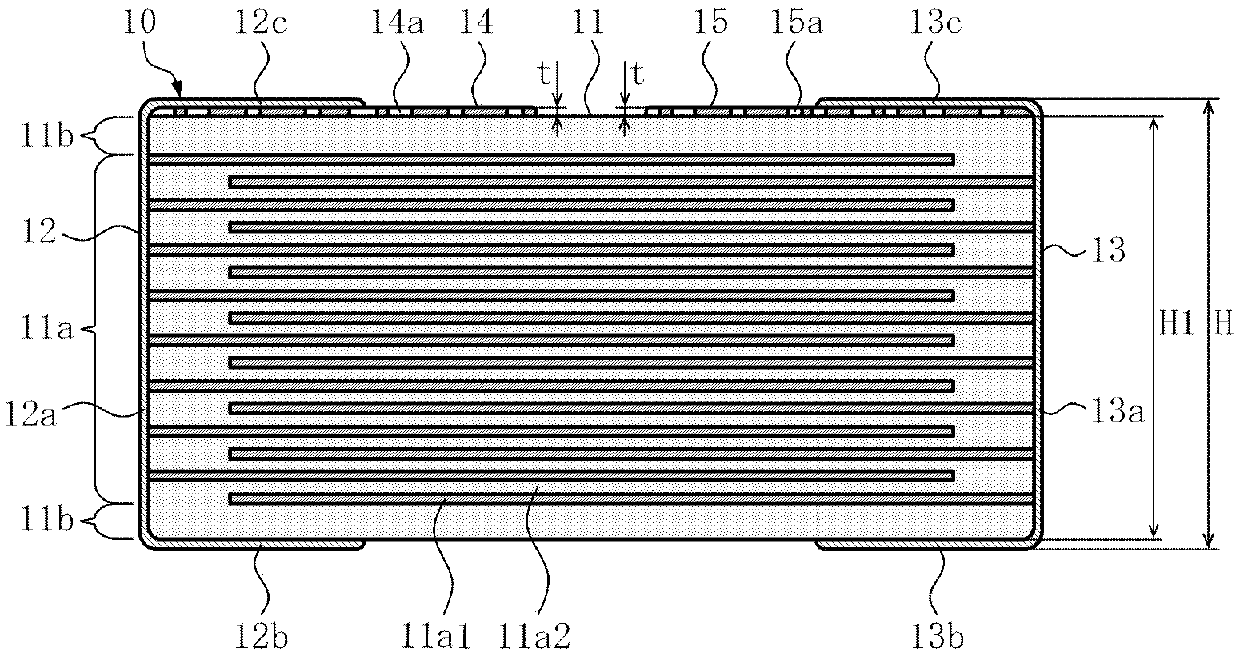

[0038] Figure 1 ~ Figure 3 Multilayer ceramic capacitor 10 according to the first embodiment of the present invention is shown. In the description below, the figure 1 The left and right direction is marked as the length direction, and the figure 1 The up and down direction of is marked as the width direction, and the figure 2 The up and down direction of is denoted as height direction, and the dimensions along the above-mentioned length direction, width direction and height direction are denoted as length, width and height, respectively.

[0039] The dimensions of multilayer ceramic capacitor 10 are specified by length L, width W, and height H. For reference, become Figure 1 ~ Figure 3 The actual dimensions of the length L, width W, and height H of the base sample are 2000 μm, 1250 μm, and 1250 μm, respectively. This multilayer ceramic capacitor 10 includes a capacitor body 11 , a first external electrode 12 , a second external electrode 13 , a first metal layer 14 , a...

no. 2 Embodiment approach 》

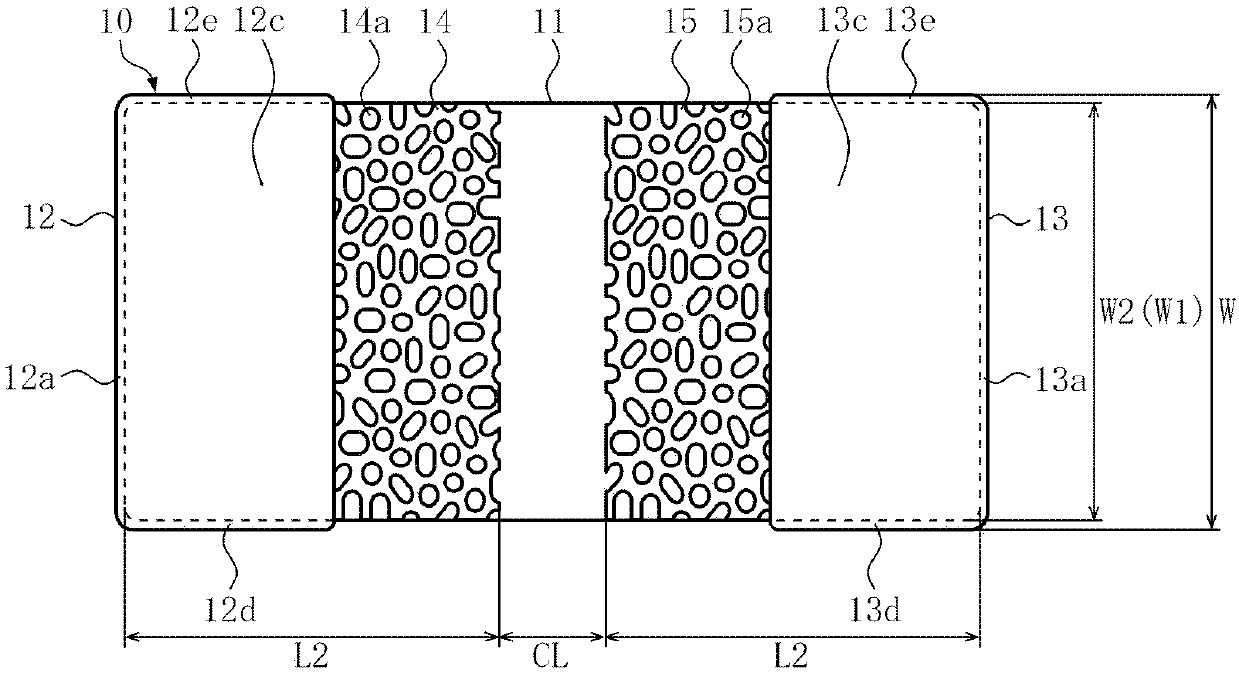

[0082] Figure 8 ~ Figure 10 A multilayer ceramic capacitor 20 according to a second embodiment of the present invention is shown. In the description below, the Figure 8 The left and right direction is marked as the length direction, and the Figure 8 The up and down direction of is marked as the width direction, and the Figure 9 The up and down direction of is denoted as the height direction, and the dimensions along the above-mentioned length direction, width direction and height direction are denoted as length, width and height, respectively.

[0083] Multilayer ceramic capacitor 20 is the same as the above-mentioned multilayer ceramic capacitor 10 (refer to Figure 1 ~ Figure 3 ) differ in structure in that an external electrode without the fourth part 12d and the fifth part 12e is used as the first external electrode 12, and an external electrode without the fourth part 13d and the fifth part is used as the second external electrode 13. Part 13e of the external elec...

no. 3 Embodiment approach 》

[0092] Figure 12 to Figure 14 A multilayer ceramic capacitor 30 according to a third embodiment of the present invention is shown. In the description below, the Figure 12 The left and right direction is marked as the length direction, and the Figure 12 The up and down direction of is marked as the width direction, and the Figure 13 The up and down direction of is denoted as the height direction, and the dimensions along the above-mentioned length direction, width direction and height direction are denoted as length, width and height, respectively.

[0093] The multilayer ceramic capacitor 30 is the same as the multilayer ceramic capacitor 10 described above (refer to Figure 1 ~ Figure 3 ) differ in structure in that an external electrode without the third part 12c, a fourth part 12d, and a fifth part 12e is used as the first external electrode 12, and an external electrode without the third part 12 is used as the second external electrode 13. The external electrodes o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com