A kind of preparation method of positive plate of bromide capacitor

A technology of capacitors and bromides, which is applied in the field of capacitors, can solve the problems of large self-discharge and low energy storage of supercapacitors, and achieve the effects of fast charge and discharge, high specific energy, and extended cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

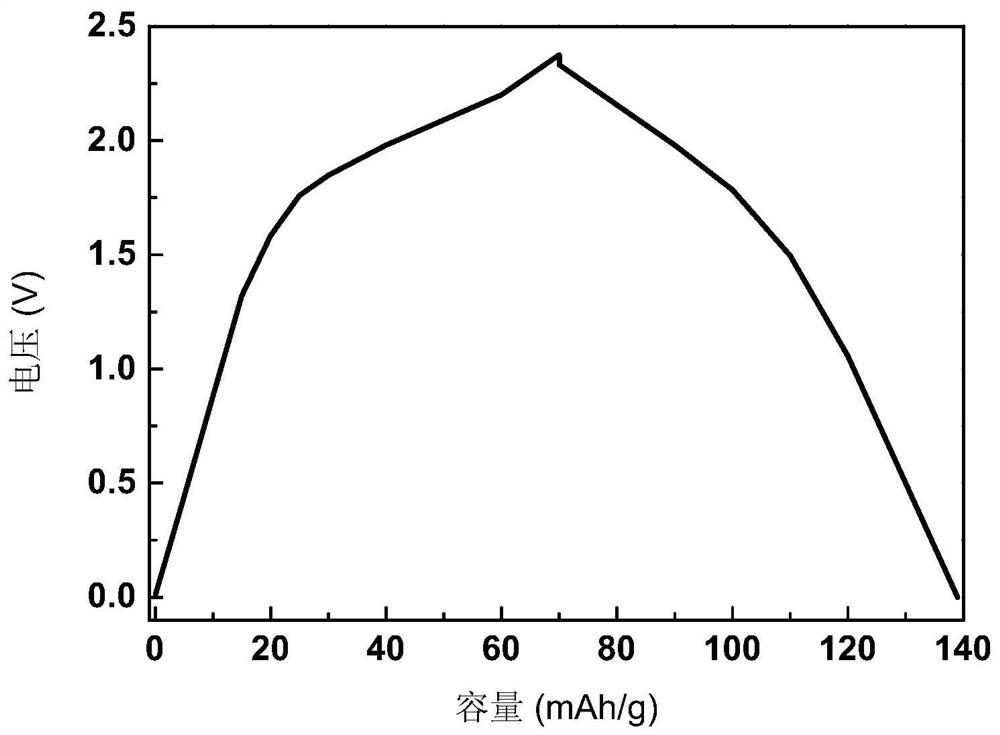

Image

Examples

preparation example Construction

[0122] (1) take bromide and put into airtight heating container, pass into inert gas; Wherein the preparation method of bromide comprises the following steps:

[0123] (a) get bromine simple substance and organic salt respectively, control the mol ratio of bromine simple substance and organic salt to be (1-4): 1, first organic salt is put into airtight container, pass into inert gas in described airtight container, so The inert gas is preferably nitrogen and / or argon;

[0124] (b) Add bromine elemental substance in airtight container, control whole process to be 1-60min, cool while stirring while dropping, temperature is controlled within 50 ℃;

[0125](c) After the dropwise addition of bromine is completed, cool to room temperature to obtain the bromide;

[0126] (2) adding solvent and high specific surface area activated carbon to the bromide, and ball milling for 12-240min to obtain slurry A;

[0127] (3) Add conductive agent to slurry A, and ball mill for 60-120min to ob...

Embodiment 1

[0134] The capacitor positive electrode slurry consists of the following components in parts by weight:

[0135] Tetrabutylammonium tribromide 15g, high specific surface area activated carbon (specific surface area is 3500m 2 / g, iodine value is 1800mg / g, moisture<0.1, ash content<1, particle size (D80) is 15-20μm, bulk specific gravity is 0.4g / ml, pH value is 7, iron impurity content<10ppm) 30g, graphite powder 10g, polyvinylidene fluoride (PVDF) 5g and N-methylpyrrolidone 40g.

[0136] Production of capacitor positive plate:

[0137] (1) take tetrabutylammonium tribromide and put into airtight container, wherein the preparation method of tetrabutylammonium tribromide comprises the following steps:

[0138] (a) get bromine simple substance and tetrabutylammonium bromide respectively, control the mol ratio of bromine simple substance and tetrabutylammonium bromide to be 1:1, tetrabutylammonium bromide is put into airtight container earlier, described airtight The container ...

Embodiment 2

[0149] Compared with Example 1, in the preparation method of bromide, raw material organic salt is N-ethyl-N-butylmorpholine bromide, and bromide is N-ethyl-N-butylmorpholine tribromide , others are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com