Poking-type sheet sorting device for coiled silicon steel sheet welding

A silicon steel sheet and sheet unscrambling technology, which is applied in the field of silicon steel sheet welding sheet unscrambling devices, can solve the problems of large distortion and deformation of silicon steel sheets, difficult release of internal stress, and difficulty in affixing equal silicon steel sheets, so as to ensure the effect of sheet unscrambling , good photo editing effect, easy-to-implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

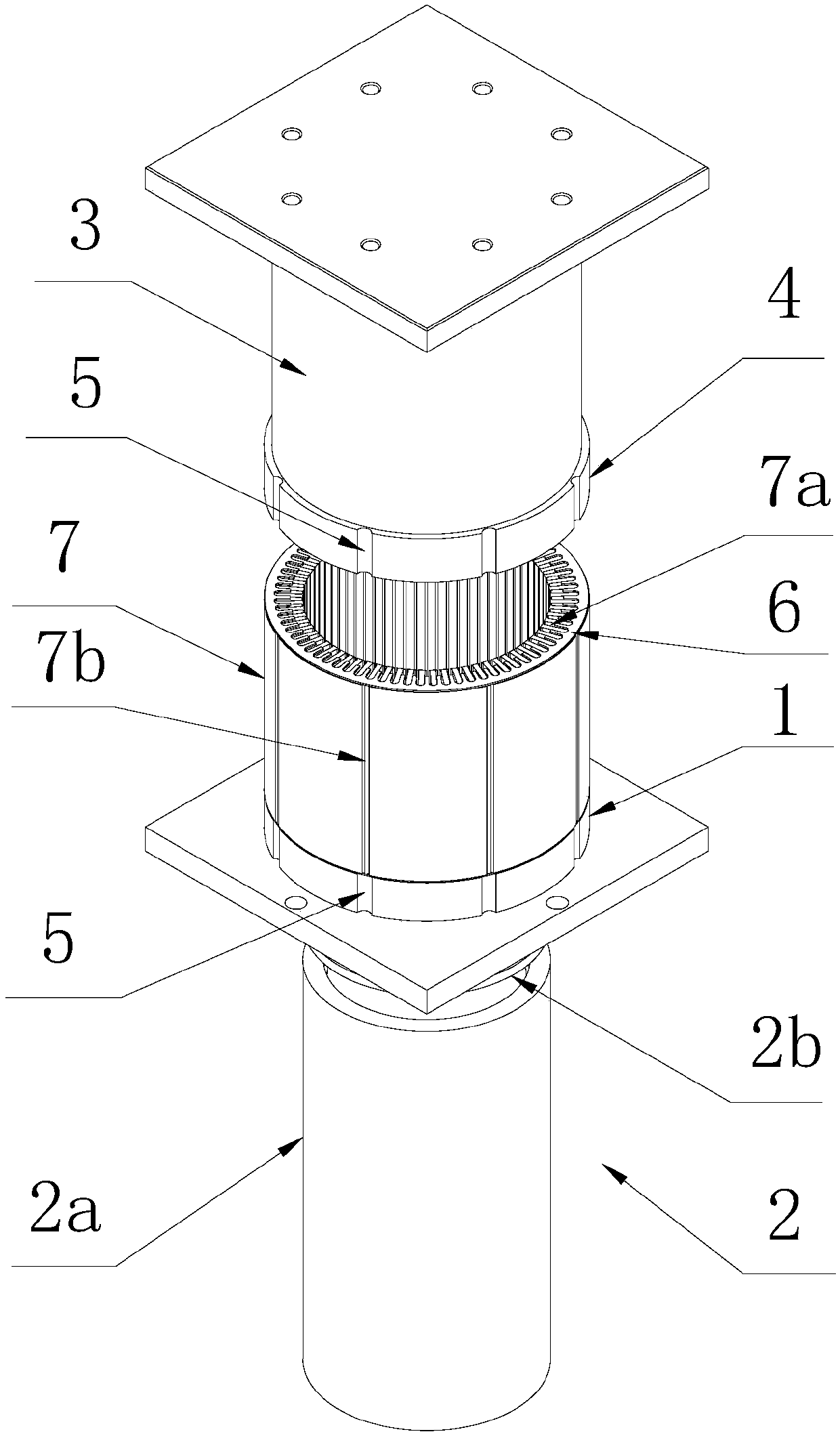

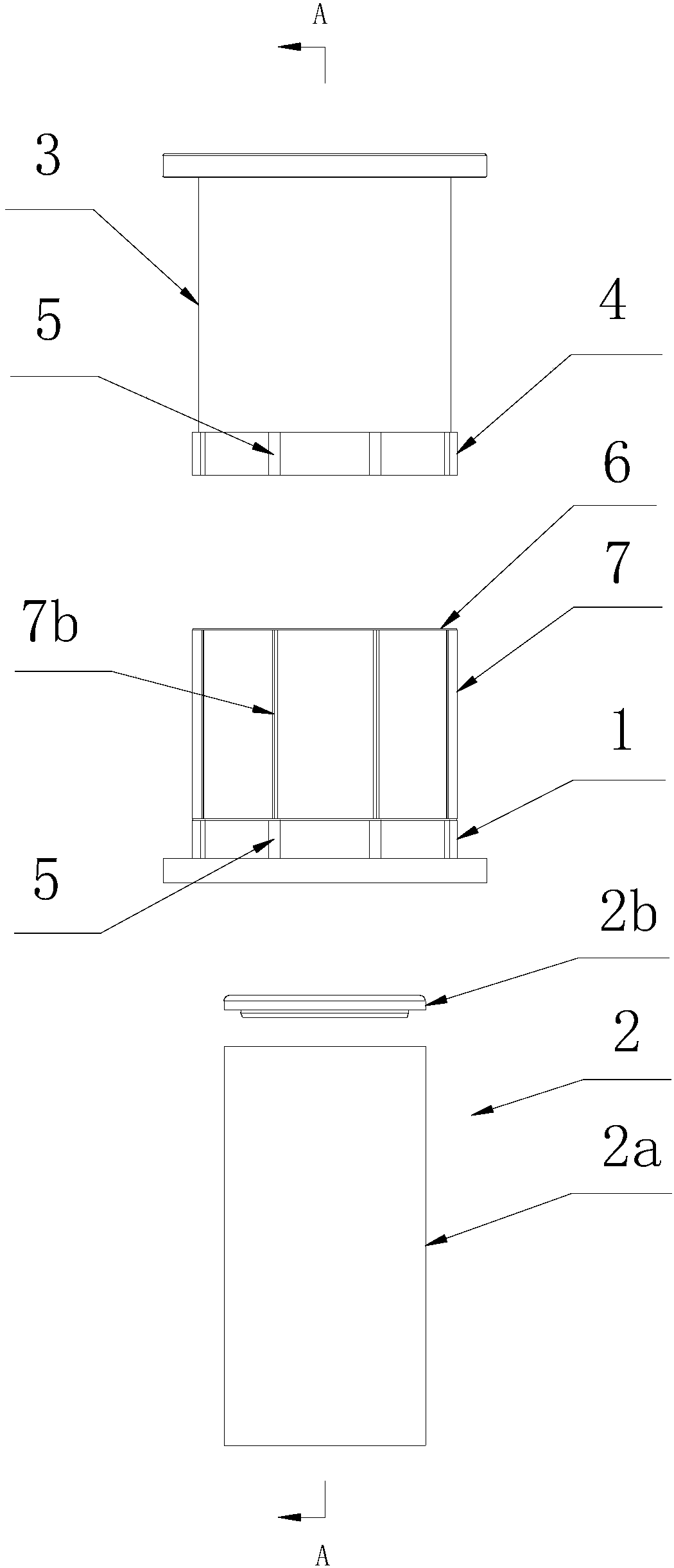

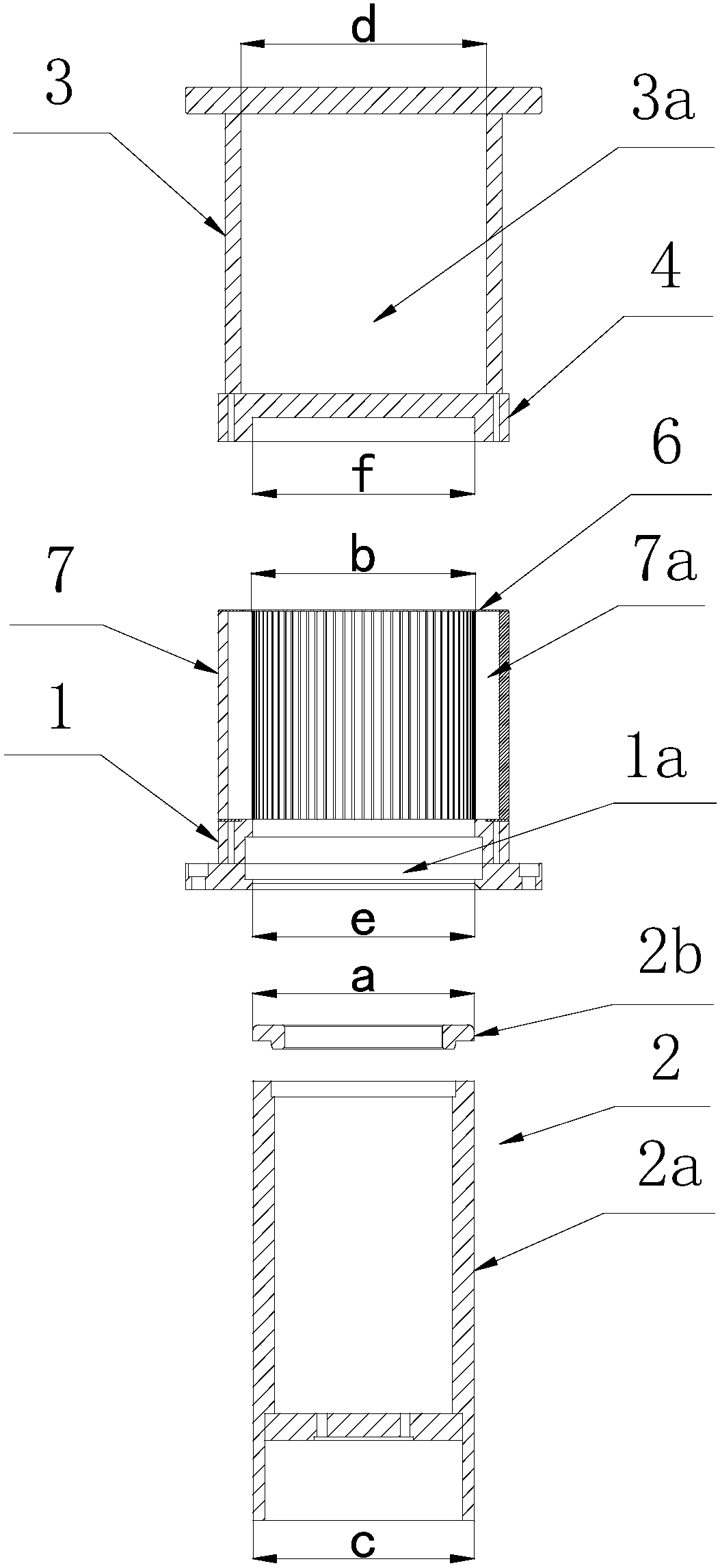

[0030] Example: Combine Figure 1~Figure 3 Shown is a specific implementation of the silicon steel sheet welding device of the present invention, which has a pressing mechanism, an intermediate positioning mechanism and an upward pushing mechanism arranged in sequence from top to bottom. The intermediate positioning mechanism is composed of The silicon steel sheet lamination seat 1 on which the silicon steel sheet 7 is stacked and two silicon steel sheet positioning rods (not shown in the figure) vertically fixed on the silicon steel sheet lamination seat 1 are jointly formed. When the silicon steel sheet 7 is stacked on the silicon steel sheet lamination seat 1, the silicon steel sheet 7 is positioned and aligned on the silicon steel sheet positioning rod by the wire slots 7a arranged at intervals in the inner ring of the silicon steel sheet. ,like figure 1 shown.

[0031] In this embodiment, the poke-up mechanism is composed of the ejector rod 2 and the punching driving de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com