Pressure-bearing type coal gas air preheater

An air preheater and coal-to-gas technology, which is applied in the field of coal chemical industry, can solve the problems of not meeting the process requirements, affecting the heat exchange efficiency, and low pressure in the tube side, so as to improve the utilization rate of heat energy, increase the calorific value of air, The effect of lowering the height of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

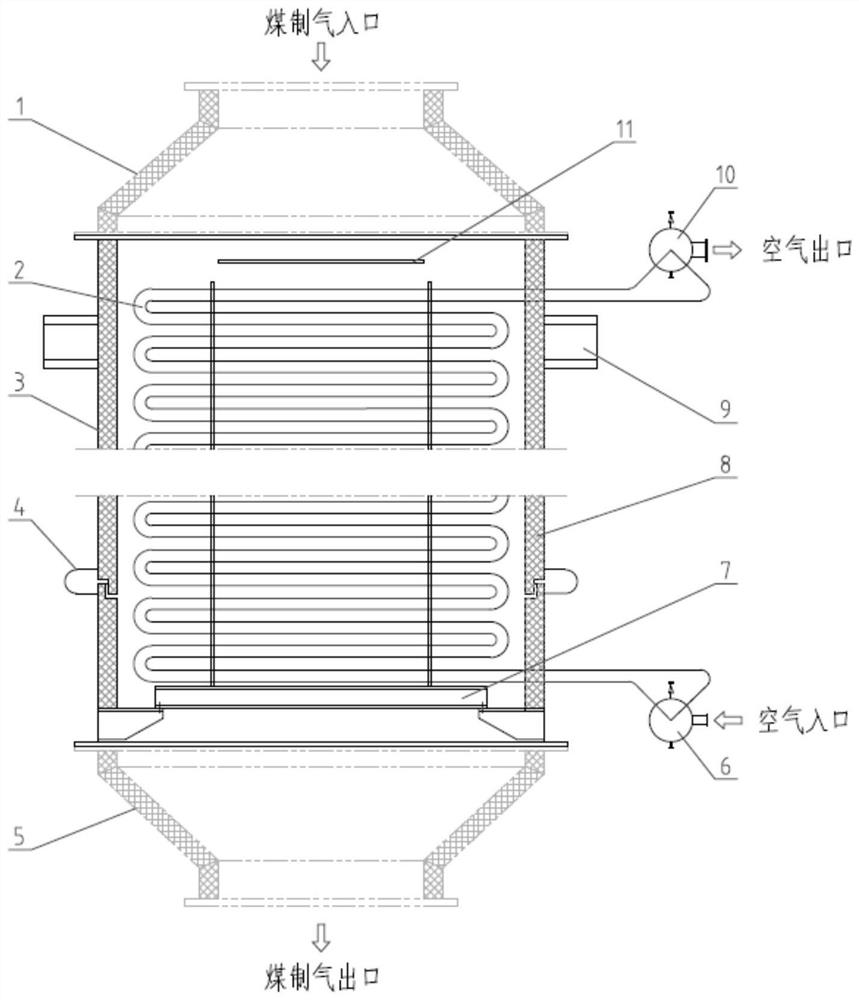

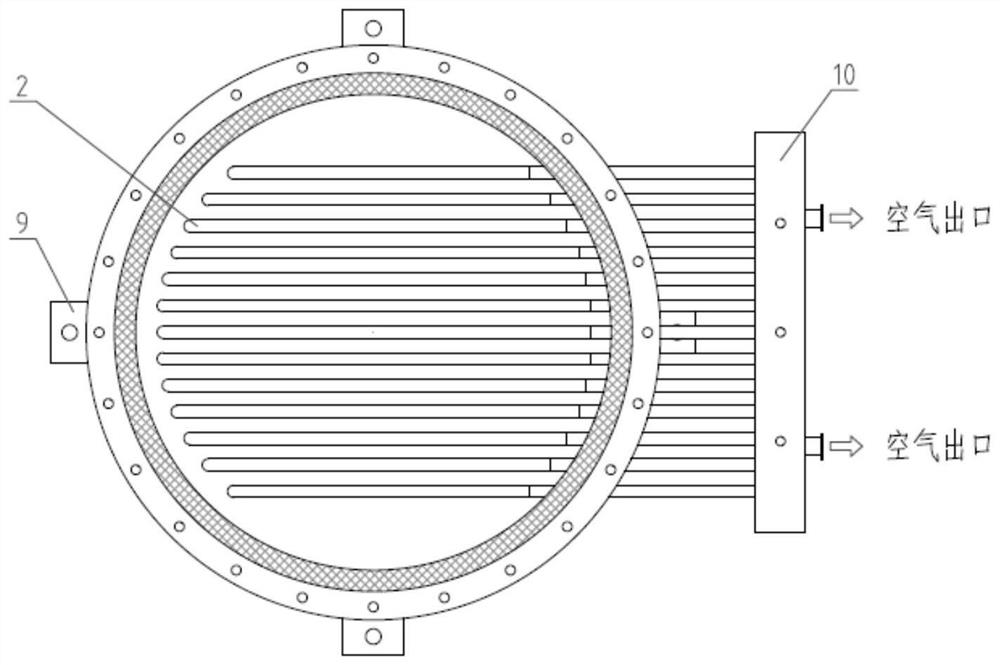

[0032] A pressurized coal gas air preheater, comprising: coal gas inlet box 1, serpentine tube 2, heat exchanger body 3, expansion joint 4, coal gas outlet box 5, air inlet header 6, Support 7, inner insulation 8, support 9, air outlet header 10, anti-shock plate 11.

[0033] The installation route of the present invention is:

[0034] Heat exchanger body—inner heat preservation—serpentine tube, anti-shock plate—air inlet and outlet headers—coal gas inlet and outlet boxes. Specific implementation steps:

[0035] 1. The 3 shell sides of the heat exchanger body, the 2 tube sides of the serpentine tube, the air inlet header 6 and the air outlet header 10 respectively complete their respective assembly welding or combined installation, namely:

[0036] 1.1 The heat exchanger body 3 shell and expansion joint 4, support 9, bottom support 7 and upper and lower flanges are assembled and welded before making heat-resistant inner insulation 8;

[0037] 1.2 2 groups of serpentine tubes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com