A Method for Improving the Cooling Condition of Steel Ingot

A technology for cooling conditions and steel ingots, applied in the field of molten metal casting, can solve the problems of slow heat dissipation of steel ingot molds, and achieve the effects of improving the quality of steel ingots, low investment and maintenance costs, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

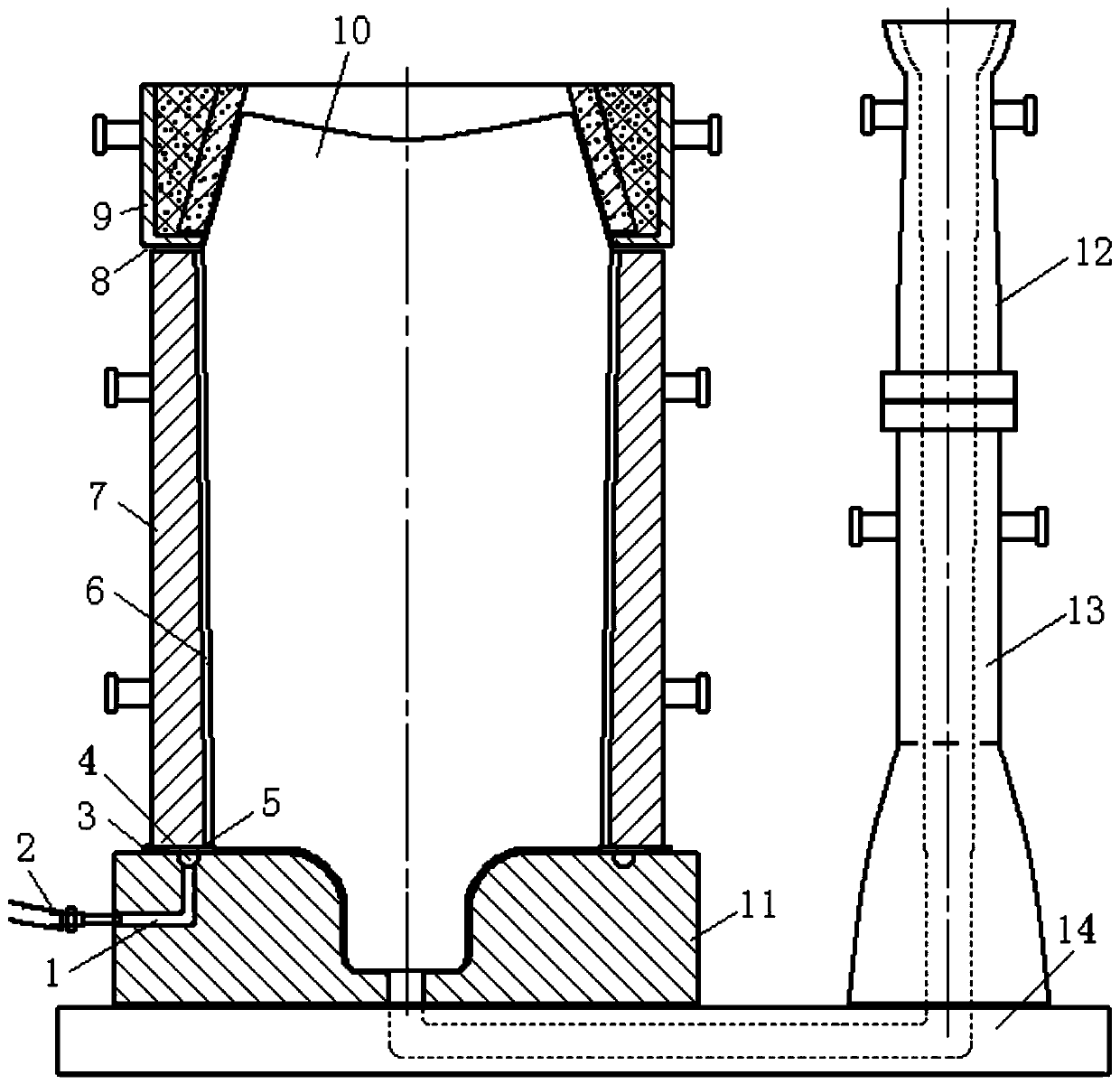

[0021] Embodiment 1: casting Q345B steel grade octagonal steel ingot with unit weight of 15 tons.

[0022] 1. Process a ring-shaped air outlet groove 4 on the circumference where the upper surface of the chassis 11 of the steel ingot mold 7 contacts the lower end of the steel ingot mold 7, and at the same time process an "L"-shaped air intake channel 1 on the side wall of the chassis 11, the air intake channel The other end of 1 communicates with outlet groove 4.

[0023] 2. Before pouring, first place the bottom plate 14 on the ground at the casting position, place the chassis 11, the upper middle injection pipe 12 and the lower middle injection pipe 13 on the bottom plate 14; then place the steel ingot mold 7 on the chassis 11, and The outer 1 / 3 part of the steel ingot mold 7 in contact with the chassis 11 is sealed with a refractory mud seal 3, and the compressed air pipe 2 is inserted into the air intake channel 1; finally, the thermal insulation cap 9 is placed on the ste...

Embodiment 2

[0028] Embodiment 2: casting single weight 38 tons of 16Mn steel type flat steel ingot.

[0029] Steps 1-3 are the same as in Example 1. The pressure in step 4 is 0.35-0.4 MPa.

[0030] In step 5, the flow rate is controlled at 150 L / min, and after maintaining for 15.5 hours, the insulation cap 9 is removed, the mold is demoulded, and the steel ingot 10 is hoisted out.

[0031] Compared with conventional casting, embodiment 2 basically eliminates the thermal resistance of the air gap between the steel ingot 10 and the steel ingot mold 7, and the cooling strength of the steel ingot 10 is improved. The time from pouring to demoulding is shortened by 1.5 hours. The sequential solidification from bottom to top is strengthened, defects such as central segregation and central porosity of the steel ingot 10 are reduced from grade 1.5 to grade 1.0, and the quality of the steel ingot 10 is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com