Straightening and bending welding device for frame spokes of safety net cover

A welding device and mesh cover technology, applied in welding equipment, wire mesh, resistance welding equipment, etc., can solve the problems of poor stability of skeleton steel rings and steel wire spokes, affecting the consistency of welding quality, and occupying a large space for equipment. uniform connection, reduce labor costs and space occupancy, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

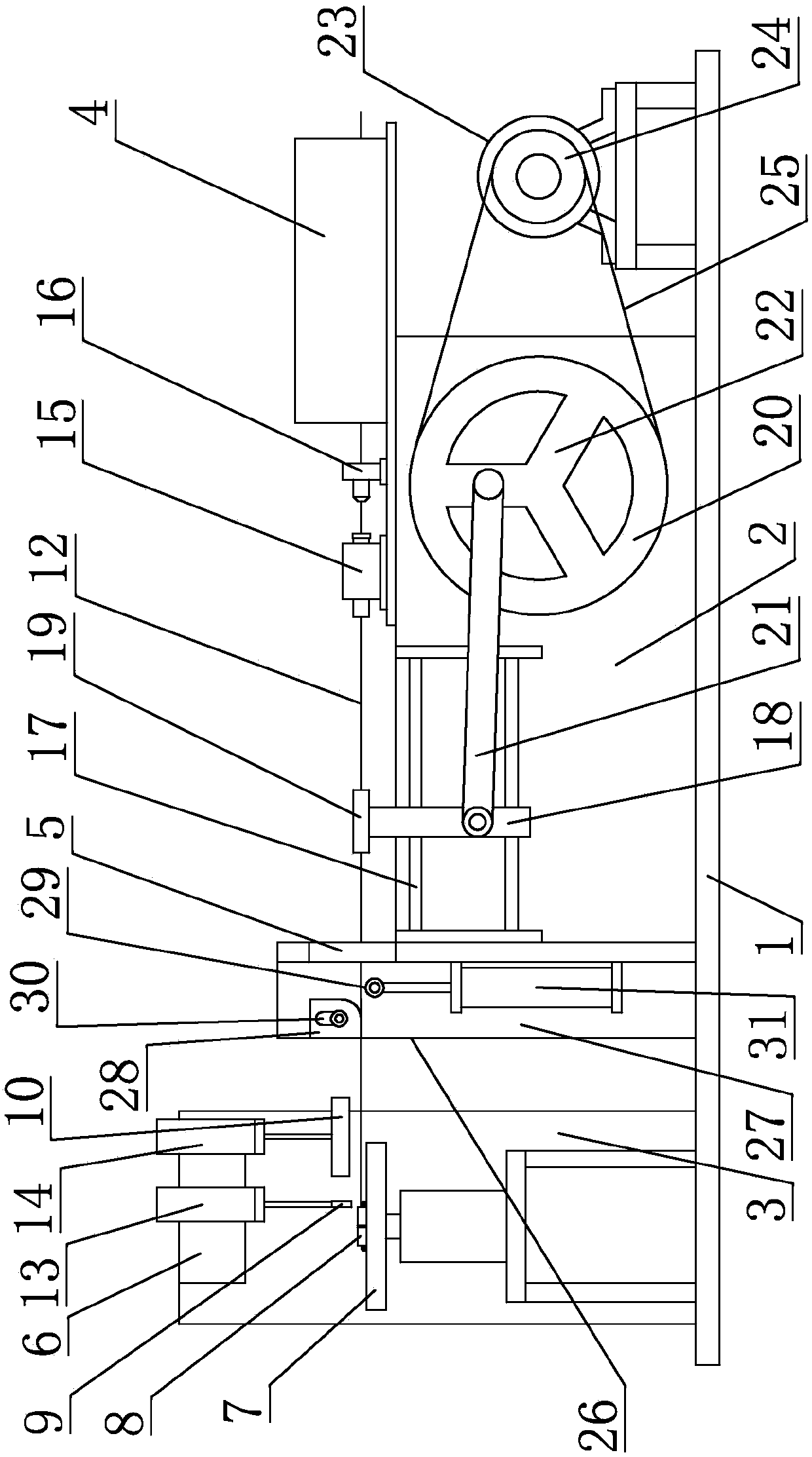

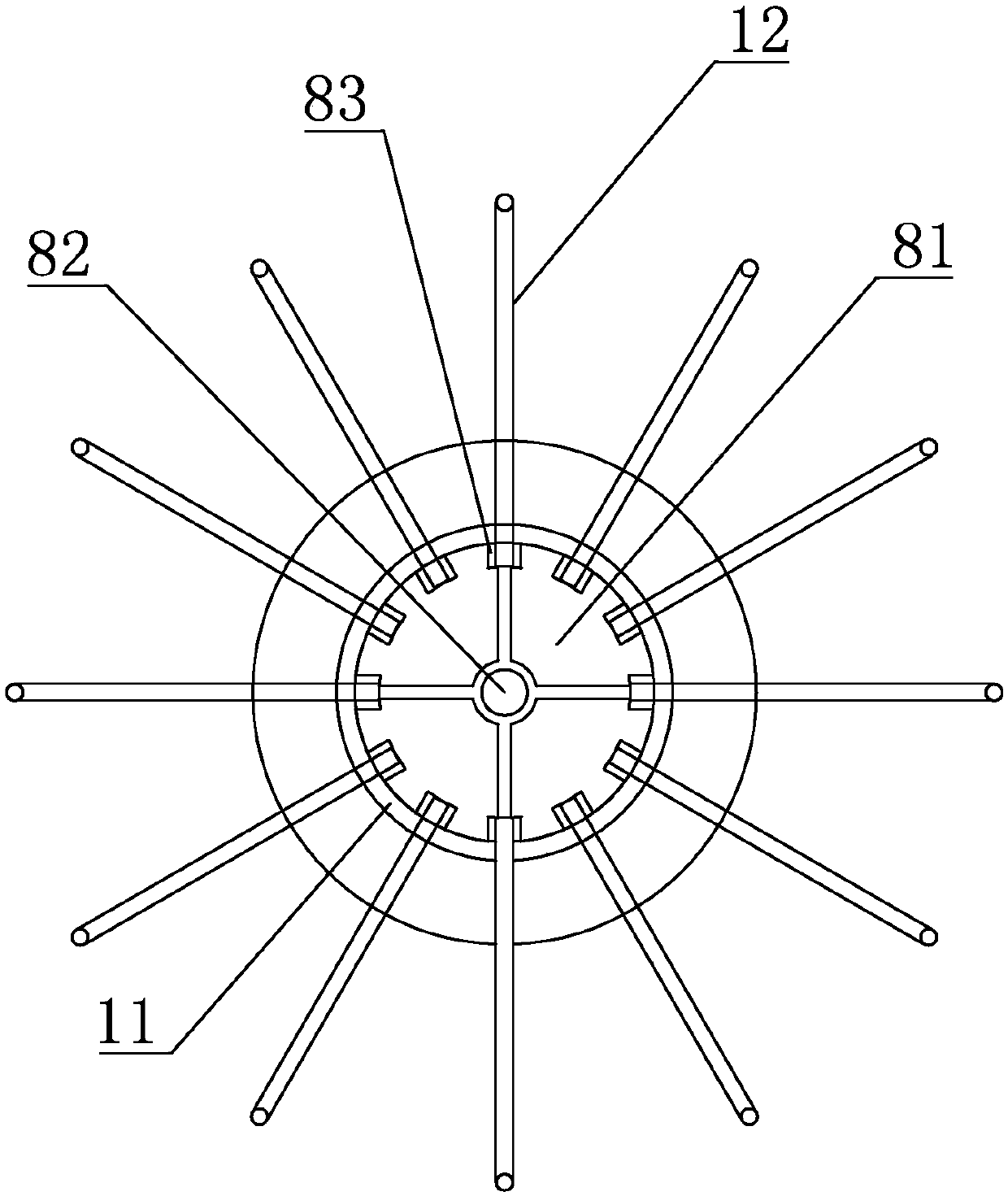

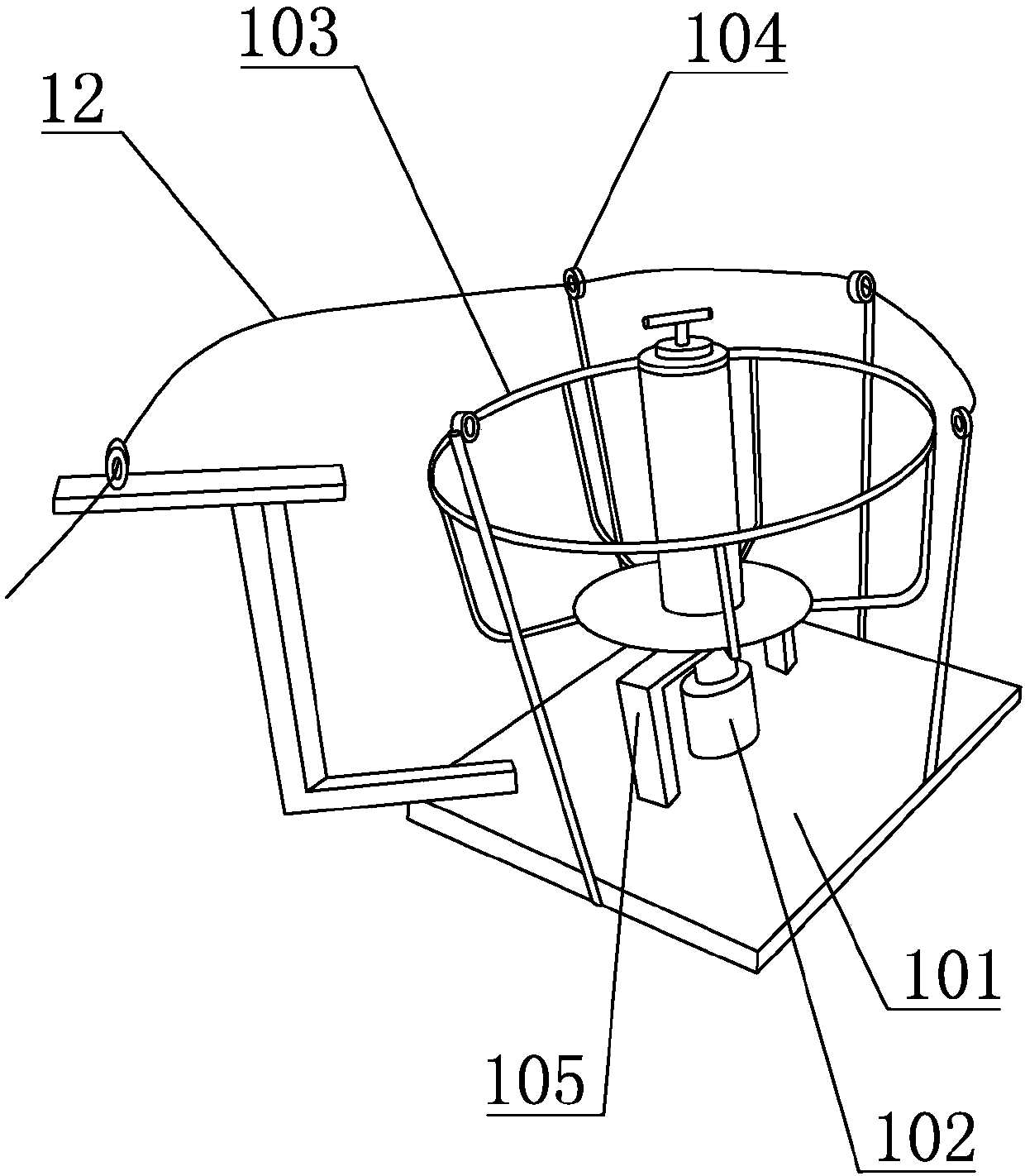

[0018] refer to Figure 1 to Figure 3 , a straightening, punching and bending welding device for spokes of a safety net cover, comprising a steel wire release device, a base 1, a welding machine and a control system, an intermediate frame 2 and a frame 3 are fixed on the base 1, and one end of the top of the intermediate frame 2 is provided There is a straightening device 4, and a cutting device 5 is provided at the other end; a forward cantilever 6 is provided on the upper part of the frame 3, and a copper driving disc 7 that can rotate counterclockwise with equal clearance is provided under the cantilever 6, and the middle part of the driving disc 7 is There is a steel ring positioning device 8 that can be retracted and expanded outward. The cantilever 6 is provided with a welding block 9 and a pressing block 10 that can be controlled by the control system to move up and down. The welding block 9 is facing the steel ring positioned on the steel ring positioning device 8. Rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com