Drilling machine lubricating system

A technology for lubrication system and drilling machine, which is applied in the direction of engine lubrication, maintenance and safety accessories, mechanical equipment, etc. It can solve the problems of complex structure and poor lubrication effect, and achieve the effect of reasonable and simple structure, convenient adjustment and easy lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

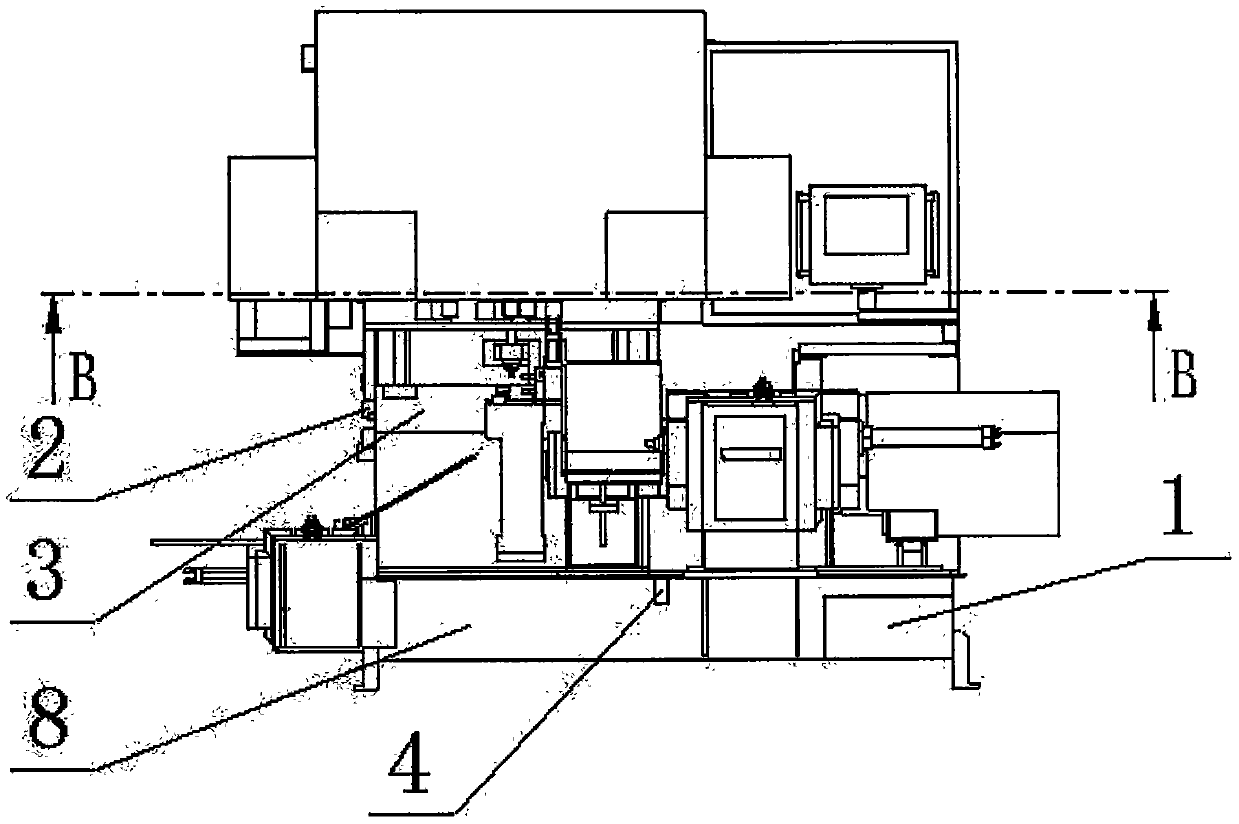

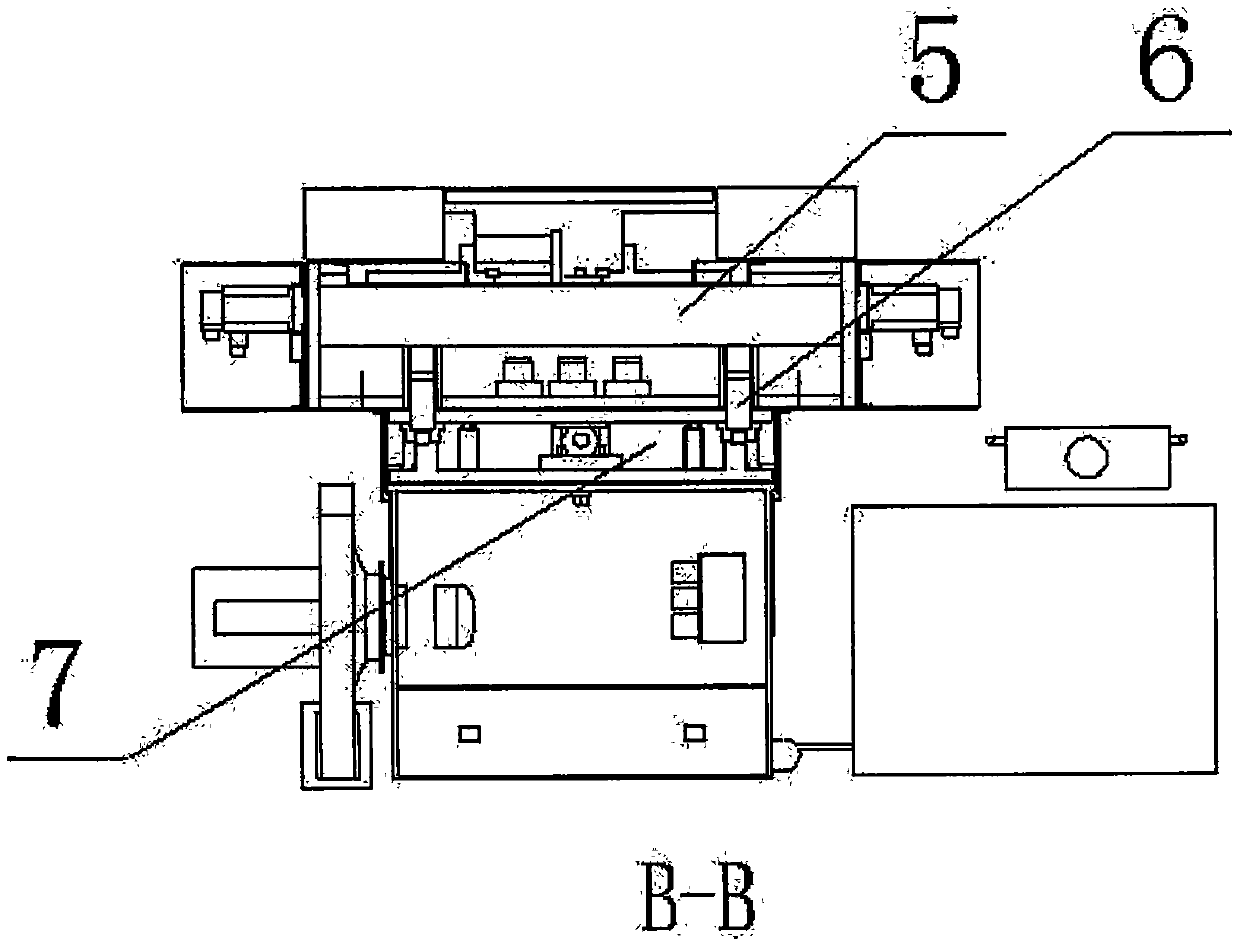

[0012] Such as Figure 1-2 As shown, a drilling machine lubrication system, which includes a lubricating oil tank 1, the left side of the lubricating oil tank 1 is provided with an equipment base 8, the upper part of the equipment base 8 is provided with an oil return pipeline channel 4, the equipment An oil receiving tank A3 is arranged above the base 8, an oil return nozzle 2 is arranged on the left side of the oil receiving tank A3, an oil receiving pan 5 is arranged above the oil receiving tank A3, and an oil receiving pan 5 is arranged below the described oil receiving pan 5 There is an oil guide groove 6, and the lower side of the oil guide groove 6 is provided with an oil receiving groove B7.

[0013] The present invention uses the interaction of lubricating oil tank, oil return nozzle, oil return pipeline channel, oil receiving pan, oil guiding groove, oil receiving groove A and oil receiving groove B to complete the lubrication of the equipment, and the lubricating oi...

Embodiment 2

[0015] Such as Figure 1-2 As shown, a drilling machine lubrication system, which includes a lubricating oil tank 1, the left side of the lubricating oil tank 1 is provided with an equipment base 8, the upper part of the equipment base 8 is provided with an oil return pipeline channel 4, the equipment An oil receiving tank A3 is arranged above the base 8, an oil return nozzle 2 is arranged on the left side of the oil receiving tank A3, an oil receiving pan 5 is arranged above the oil receiving tank A3, and an oil receiving pan 5 is arranged below the described oil receiving pan 5 There is an oil guide groove 6, and the lower side of the oil guide groove 6 is provided with an oil receiving groove B7, using the lubricating oil tank 1, the oil return nozzle 2, the oil return pipeline channel 4, the oil receiving plate 5, the oil guide groove 6, the oil receiving groove A3 and the oil receiving groove The mutual cooperation of B7 completes the principle of equipment lubrication. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com