Air channel device of locomotive traction motors

A technology for traction motors and air ducts, applied to locomotives, etc., can solve problems such as bolts falling off, traction motor temperature burnout, air duct leakage, etc., achieve quick installation or disassembly, high transportation costs, and ensure safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

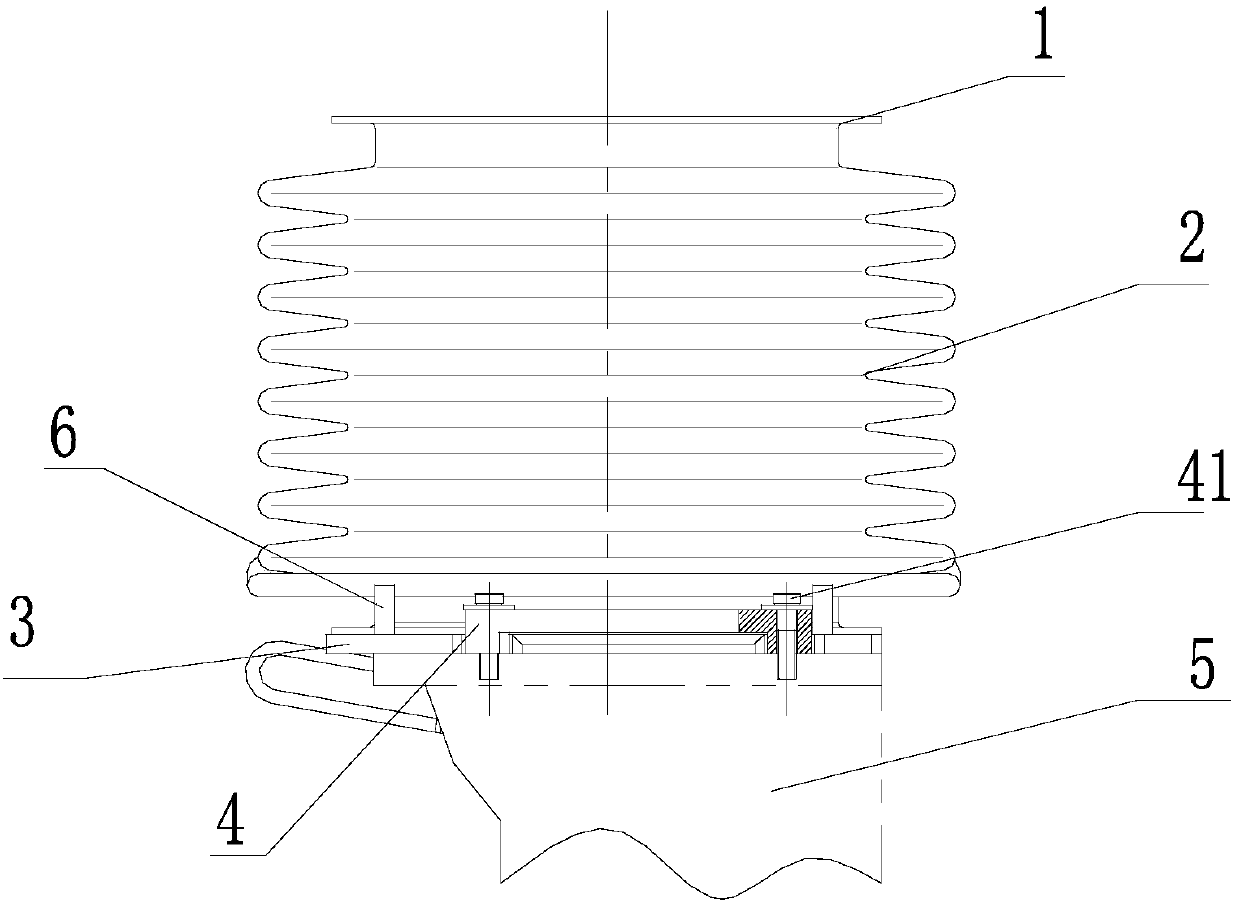

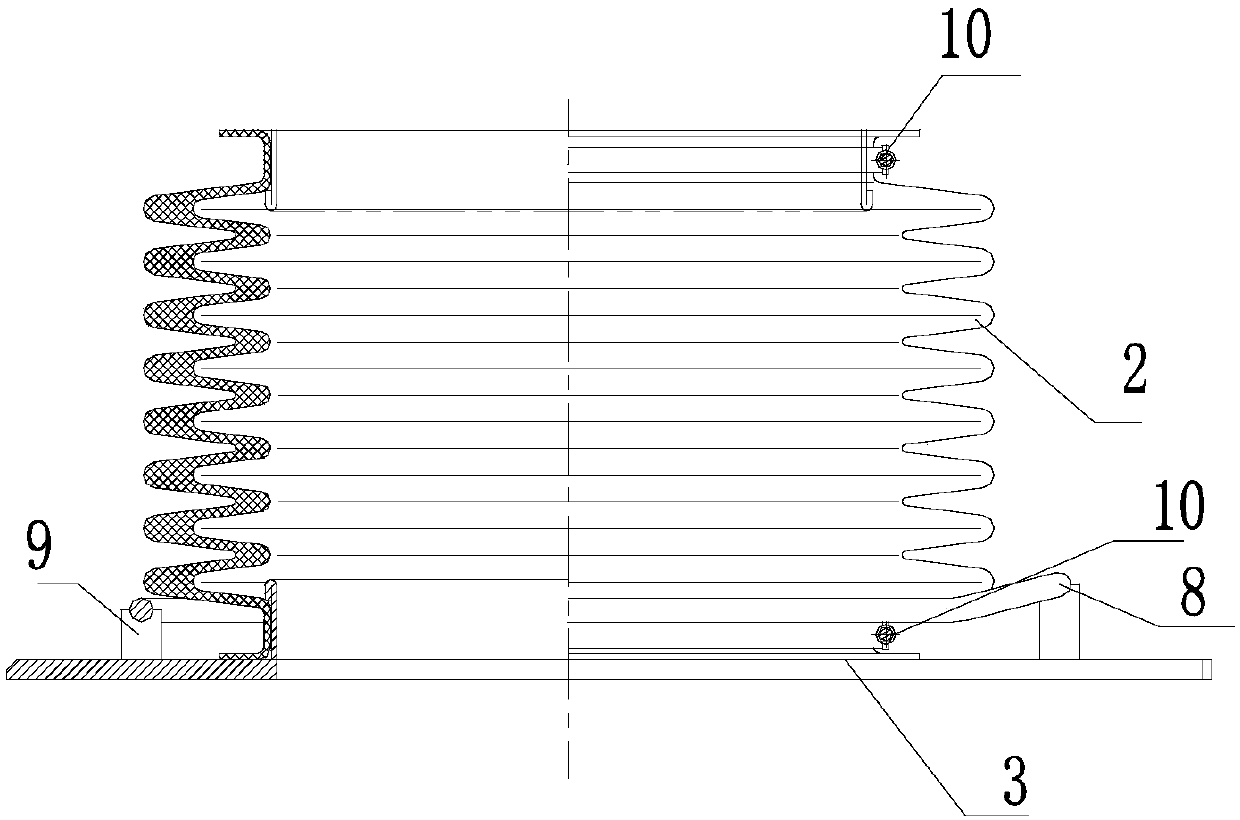

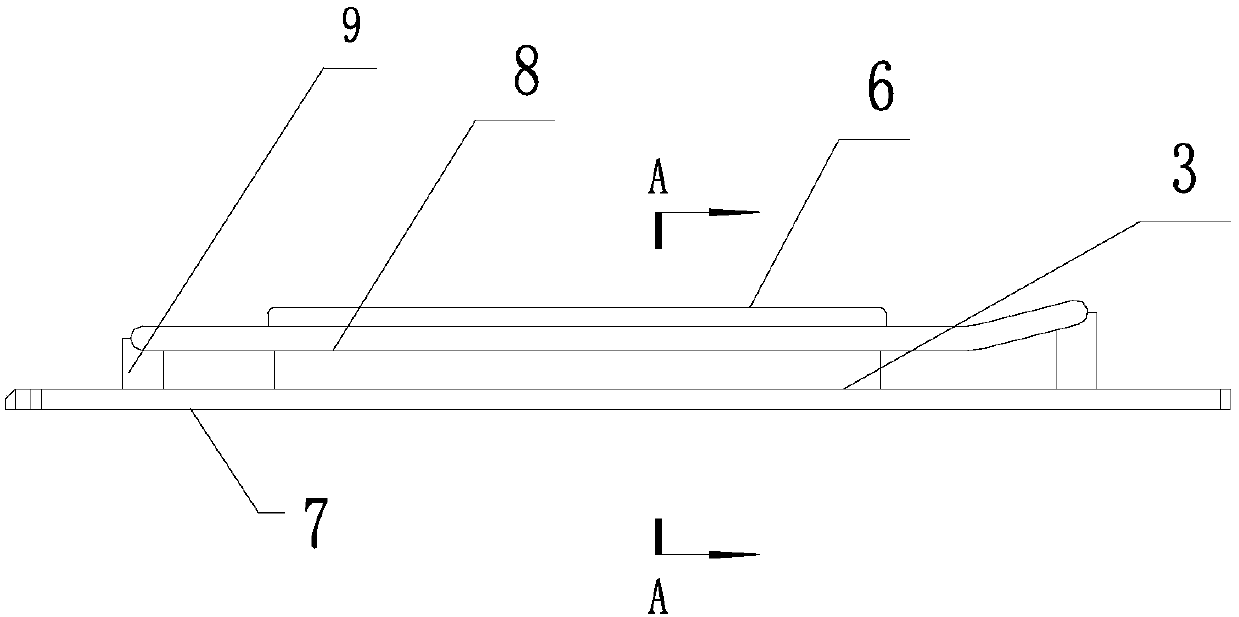

[0022] The air duct device of the locomotive traction motor will be further described below in conjunction with the accompanying drawings.

[0023] In this locomotive traction motor air duct device, the upper flange 1 is welded on the chassis of the car body, one end of the air duct hose 2 is fixed to the upper flange 1 through a throat clamp 10, and the other end of the air duct hose 2 is assembled with the base 3 One side of the lower flange 6 is fixed by a throat clamp 10, the stop block 4 is fixed on the air inlet 5 of the traction motor, and the flange bottom plate 7 of the base assembly 3 is inserted into the stop block 4. The shape of the stopper 4 is "凵" type. Base assembly 3 is welded by flange bottom plate 7, handle 8, handle support seat 9 and lower flange 6, handle 8, handle support seat 9 and lower flange 6 are welded on the same side plane of flange bottom plate 7, the lower The flange 6 is welded at the center of the flange bottom plate 7, the handle support se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com