Wind-proof mud guard capable of preventing bicycle from being pushed over

A technology for fenders and bicycles, which is applied in the direction of fenders, bicycle accessories, bicycle brackets, etc., and can solve problems such as bicycle damage, mud contamination, and easy failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

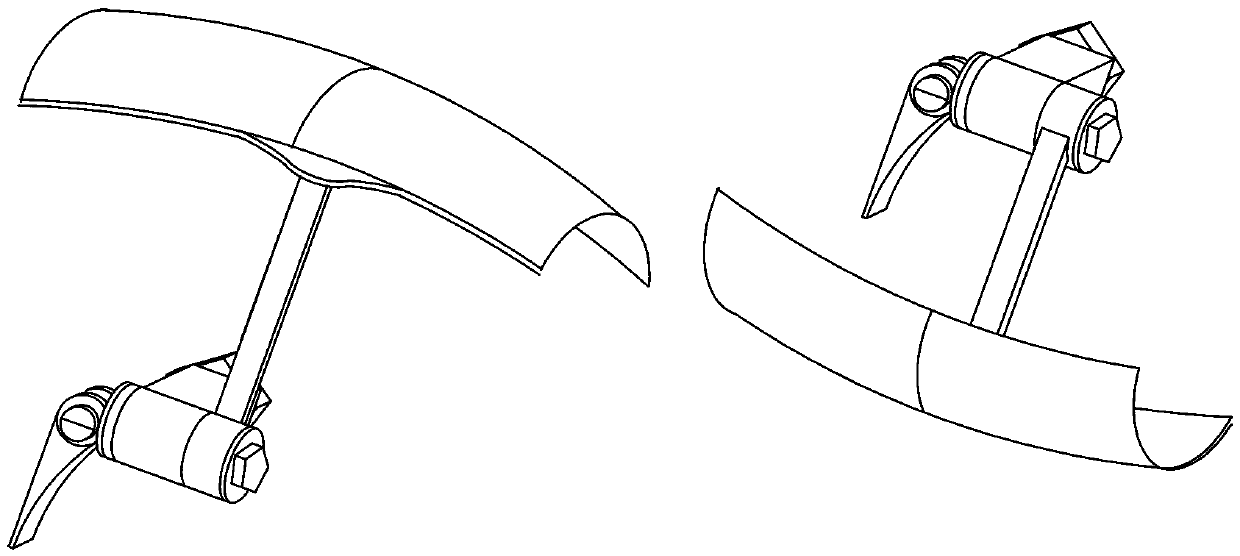

[0036] Such as Figure 1-Figure 3 , The top of the 201 quick-release wrench is equivalent to a cam structure, relying on the rotation of the 201 quick-release wrench to achieve the purpose of fastening the windproof and preventing the bicycle fender from being pushed down. When the 203 first metal gasket, 204 elastic gasket, 205 first fixed block, 206 second fixed block and 207 second metal gasket are fixed between the quick release screw cap on the 201 quick release wrench and the 208 set screw , by turning the 201 quick release wrench, when the 201 quick release wrench is in the open state, the cam is in the state of the smallest diameter, the quick release screw cap, 203 first metal gasket, 204 elastic gasket, 205 first fixed block, 206 There is a gap among the second fixing block, the second metal washer 207 and the fixing screw 208.

[0037] When the 201 quick release wrench is in the closed state, the cam is in the state with the largest diameter, and the 201 quick rele...

no. 2 example

[0040] Installation steps: such as Figure 1-Figure 3 .

[0041] First, fix the 205 first fixed block on the 102 rear wheel center axle screw.

[0042] Then, adjust the deflection angle of the 205 first fixed block through the screw cap on the 102 rear wheel central axis screw.

[0043]Then, snap the 202 wrench screw caps into the two round holes on the top of the 201 quick release wrench.

[0044] Then, use 208 fixing screws to string together the 207 second metal spacer, the 206 second fixed block, the 205 first fixed block, the 204 elastic spacer and the 203 first metal spacer from right to left.

[0045] Then, screw the leftmost end of the 208 set screw into the 202 wrench screw cap.

[0046] Then, fine-tune the degree of tightness between the 208 set screw and the 202 wrench screw cap.

[0047] Finally, rotate the 210 fender to a suitable angle, and rotate the 201 quick release wrench to fix it, thus completing the installation.

no. 3 example

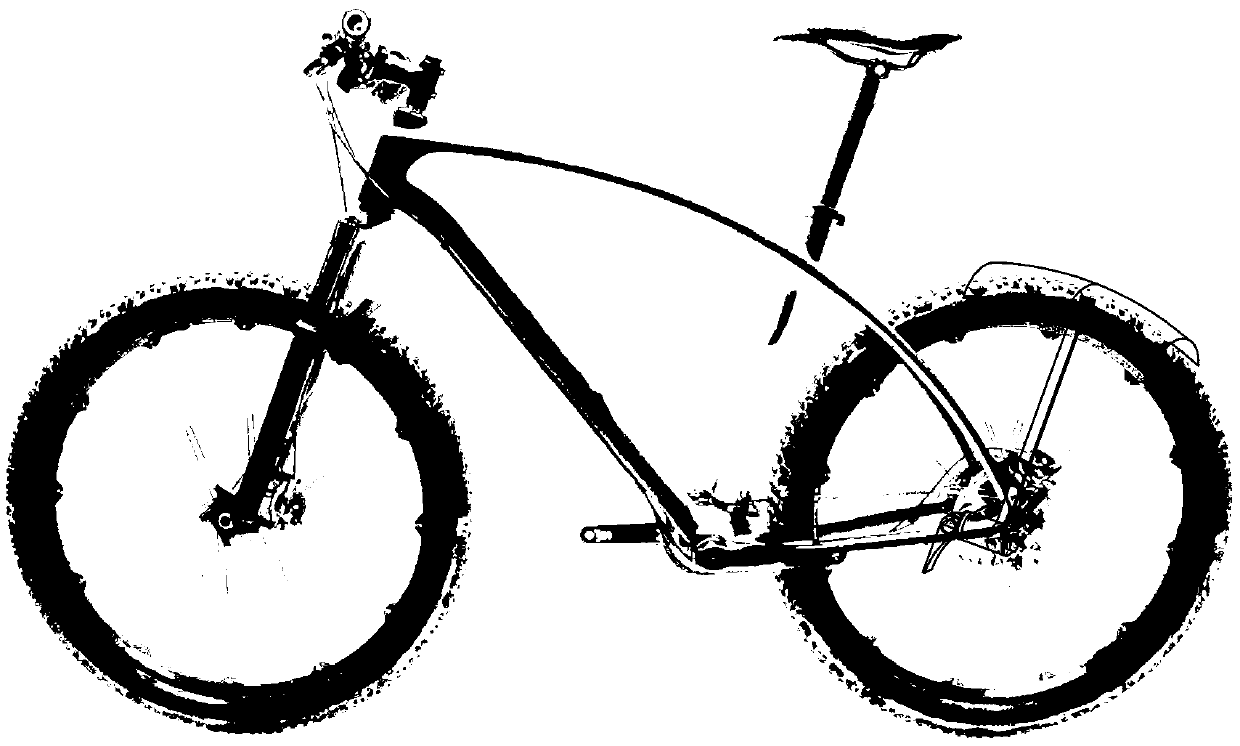

[0049] Such as Figure 3-Figure 8 , when the wind blows, first, put down the bike kickstand.

[0050] Then, rotate the 201 quick release wrench so that the 201 quick release wrench is in the open state, the quick release screw cap, 203 first metal gasket, 204 elastic gasket, 205 first fixed block, 206 second fixed block, 207 second metal pad There is a gap between the sheet and the 208 setscrew.

[0051] Then, the 210 fenders are rotated down so that the 210 fenders are in contact with the ground.

[0052] Then, rotate the 201 quick-release wrench so that the 201 quick-release wrench is in the closed state, and the 201 quick-release wrench and the 208 fixing screw connect the 203 first metal gasket, 204 elastic gasket, 205 first fixed block, 206 second fixed block and 207 The second metal gaskets are tightly fixed together, so as to realize the conversion of functions, from the bicycle fender to the quick conversion of the function of the bicycle foot support bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com