Production method and system of granular silicon

A production method and production system technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of reducing the purity of silicon in the production of granules, and achieve the effect of ensuring accuracy and sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

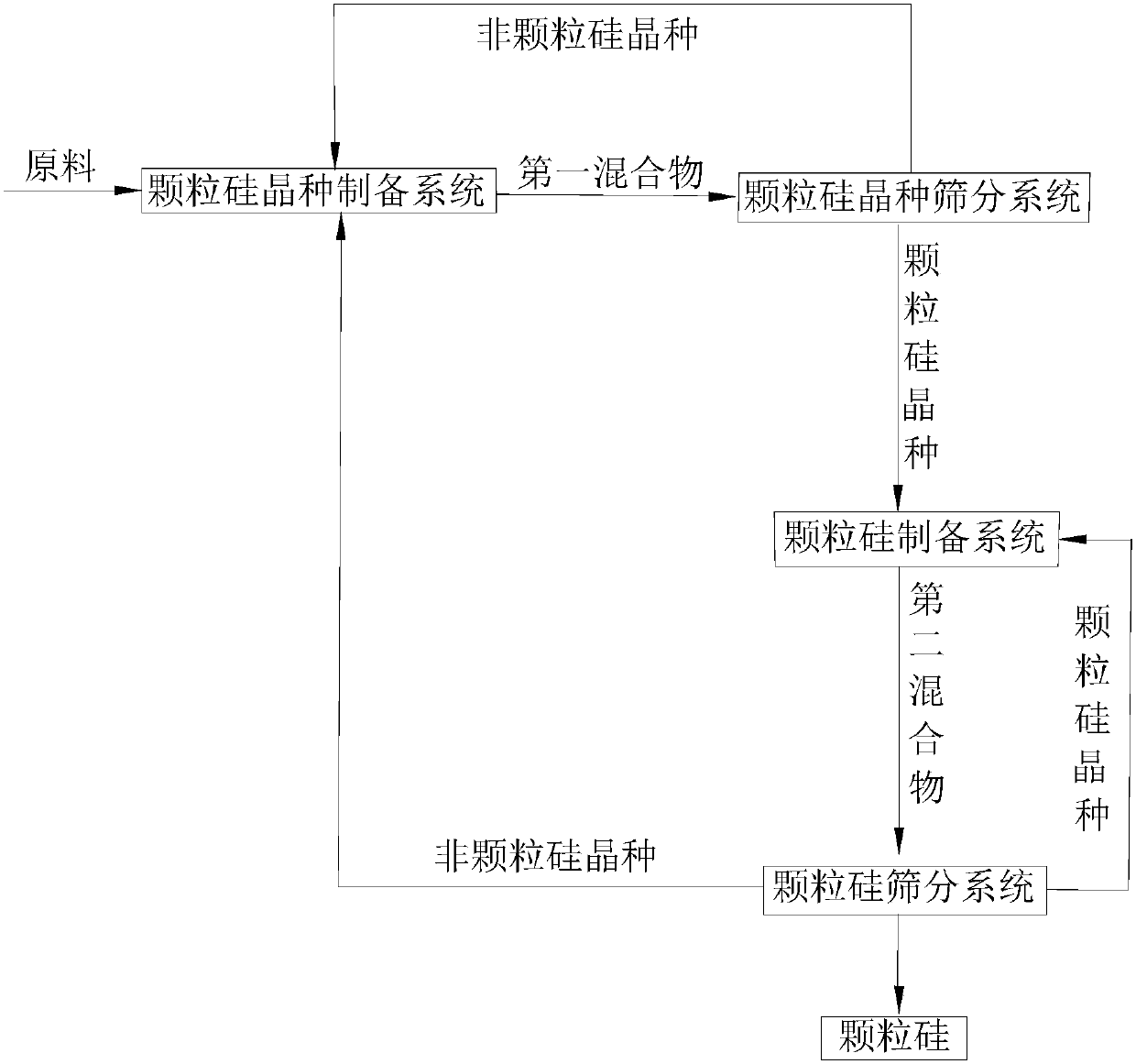

Image

Examples

Embodiment 1

[0053] The polysilicon charge is processed to obtain a first mixture comprising non-particulate silicon seeds and granular silicon seeds. Specifically include: heating the polysilicon material to form a polysilicon liquid flow, and the heating temperature is 1000°C; dispersing the polysilicon liquid flow into polysilicon droplets, specifically including, using hydrogen gas at 100°C to impact the outflowing polysilicon liquid flow at a speed of 10m / s Dispersing the polysilicon liquid flow into polysilicon droplets; cooling the polysilicon droplets into a first mixture comprising non-granular silicon seeds and granular silicon seeds, specifically comprising, further transporting the polysilicon droplets along with hydrogen to a temperature of 100° C. In the polysilicon droplet cooling device, the polysilicon liquid flow is changed into a first mixture comprising non-granular silicon seed crystals and granular silicon seed crystals.

[0054] sieving the first mixture to separate ...

Embodiment 2

[0060] The polysilicon charge is processed to obtain a first mixture comprising non-particulate silicon seeds and granular silicon seeds. Specifically include: heating the polysilicon material to form a polysilicon liquid flow, and the heating temperature is 1800°C; dispersing the polysilicon liquid flow into polysilicon droplets, specifically including, using hydrogen gas at 100°C to impact the outflowing polysilicon liquid flow at a speed of 10m / s Dispersing the polysilicon liquid flow into polysilicon droplets; cooling the polysilicon droplets into a first mixture comprising non-granular silicon seeds and granular silicon seeds, specifically comprising, further transporting the polysilicon droplets along with hydrogen to a temperature of 100° C. In the polysilicon droplet cooling device, the polysilicon liquid flow is changed into a first mixture comprising non-granular silicon seed crystals and granular silicon seed crystals.

[0061] sieving the first mixture to separate ...

Embodiment 3

[0067] The polysilicon charge is processed to obtain a first mixture comprising non-particulate silicon seeds and granular silicon seeds. Specifically include: heating the polysilicon material to form a polysilicon liquid flow, and the heating temperature is 2300°C; dispersing the polysilicon liquid flow into polysilicon droplets, specifically including, using hydrogen gas at 100°C to impact the outflowing polysilicon liquid flow at a speed of 10m / s Dispersing the polysilicon liquid flow into polysilicon droplets; cooling the polysilicon droplets into a first mixture comprising non-granular silicon seeds and granular silicon seeds, specifically comprising, further transporting the polysilicon droplets along with hydrogen to a temperature of 100° C. In the polysilicon droplet cooling device, the polysilicon liquid flow is changed into a first mixture comprising non-granular silicon seed crystals and granular silicon seed crystals.

[0068] sieving the first mixture to separate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com