A compound desensitizing agent for pyrotechnic powder of fireworks and firecrackers

A kind of fireworks and firecrackers, composite technology, applied in the direction of non-explosive desensitizer/passivator, non-explosive/non-thermal agent components, explosives, etc. Deliquescence and other problems, to achieve the effect of good explosive force, strong work ability, and avoid heating and spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: A kind of composite desensitizing agent for pyrotechnic powder of fireworks and firecrackers, is made up of the following components of weight and number ratio: 40 parts of magnesium oxide, 5 parts of calcium stearate, 1 part of bismuth trioxide, bicyclic Pentadiene iron 10 parts, phthalic anhydride 5 parts. According to the above ratio, each component was weighed and fully stirred and sieved to obtain a 120-mesh impurity-free passivator product.

Embodiment 2-5

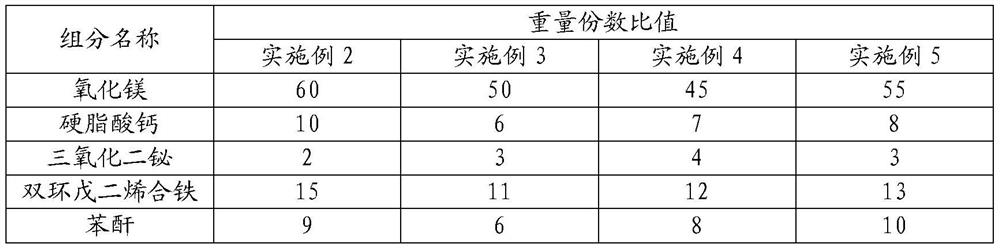

[0017] Embodiment 2-5 differs from embodiment 1 in that the proportioning of each component is different, see the following table:

[0018]

[0019] The composite desensitizers prepared in the above-mentioned embodiments can be compounded by the manufacturers themselves according to the effect requirements to make deactivated fireworks and firecrackers explosives, propellants and low-sensitivity, high-stability bright beads. for example:

[0020] Explosives: prepared according to the ratio of parts by weight, composite desensitizer: aluminum powder: potassium perchlorate = 10:10:20, and mixed uniformly according to the general method. The cracking explosive configured with this compound desensitizing agent is equipped with 12g of bright beads in the inner cylinder, which is equivalent to the traditional cracking charge of 3.6g, and the diameter of the blasting surface is 15-20 meters, which meets the standard.

[0021] Propellant: prepared according to the ratio of parts b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com