Processing technology for rock asphalt modified asphalt by adopting oil grinding method

A technology of modified asphalt and processing technology, applied in building components, building insulation materials, buildings, etc., can solve problems such as destroying the activity of rock asphalt, and achieve the effect of reducing carbonization, obvious effect and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

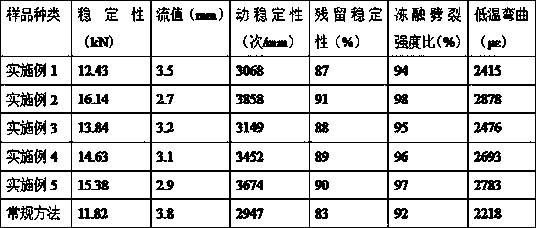

Examples

Embodiment 1

[0018] A processing technology of rock asphalt modified asphalt oil grinding method, comprising the following steps:

[0019] (1) Break rock asphalt to a particle size of less than 3mm, dehydrate and activate it at 140°C, and control the dehydration

[0020] The water content in rock asphalt is 5%, and the carbonization phenomenon cannot be found by naked eyes;

[0021] (2) The asphalt treated in step (1) was fused with the base asphalt at a low temperature of 140°C for 15 minutes to obtain the asphalt modified asphalt;

[0022] (3) The asphalt-modified asphalt prepared in step (2) is shear-milled at a shear speed of 1000-1500 rpm at 140°C until the fineness is below -100 mesh.

Embodiment 2

[0024] A processing technology of rock asphalt modified asphalt oil grinding method, comprising the following steps:

[0025] (1) Break rock asphalt to a particle size of less than 3mm, dehydrate and activate it at 145°C, and control the dehydration

[0026] The water content in rock asphalt is 4%, and the carbonization phenomenon cannot be found by naked eyes;

[0027] (2) The asphalt treated in step (1) was fused with the base asphalt at a low temperature of 145°C for 16 minutes to obtain the asphalt-modified asphalt;

[0028] (3) The asphalt-modified asphalt prepared in step (2) is shear-milled at a shear speed of 1000-1500 rpm at 145°C until the fineness is below -100 mesh.

Embodiment 3

[0030] A processing technology of rock asphalt modified asphalt oil grinding method, comprising the following steps:

[0031] (1) Crushing rock asphalt to a particle size of less than 3mm, dehydrating and activating it at 149°C, and controlling the dehydration

[0032] The water content in rock asphalt is 3.5%, and the carbonization phenomenon cannot be found by naked eyes;

[0033] (2) The asphalt treated in step (1) was fused with the base asphalt at a low temperature of 149°C for 17 minutes to obtain the asphalt-modified asphalt;

[0034] (3) The asphalt-modified asphalt prepared in step (2) is shear-milled at a shear speed of 1000-1500 rpm at 149°C until the fineness is below -100 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com