Parallel breathing type single-plate silo solid carbon fuel cell stack and power generation method thereof

A fuel cell stack and breathing technology, applied in fuel cells, electrochemical generators, circuits, etc., can solve the problems of large circuit consumption in the battery, low battery working efficiency, high reaction temperature, etc., to improve electrode efficiency and fuel efficiency , Reduce the consumption of the circuit in the battery and reduce the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

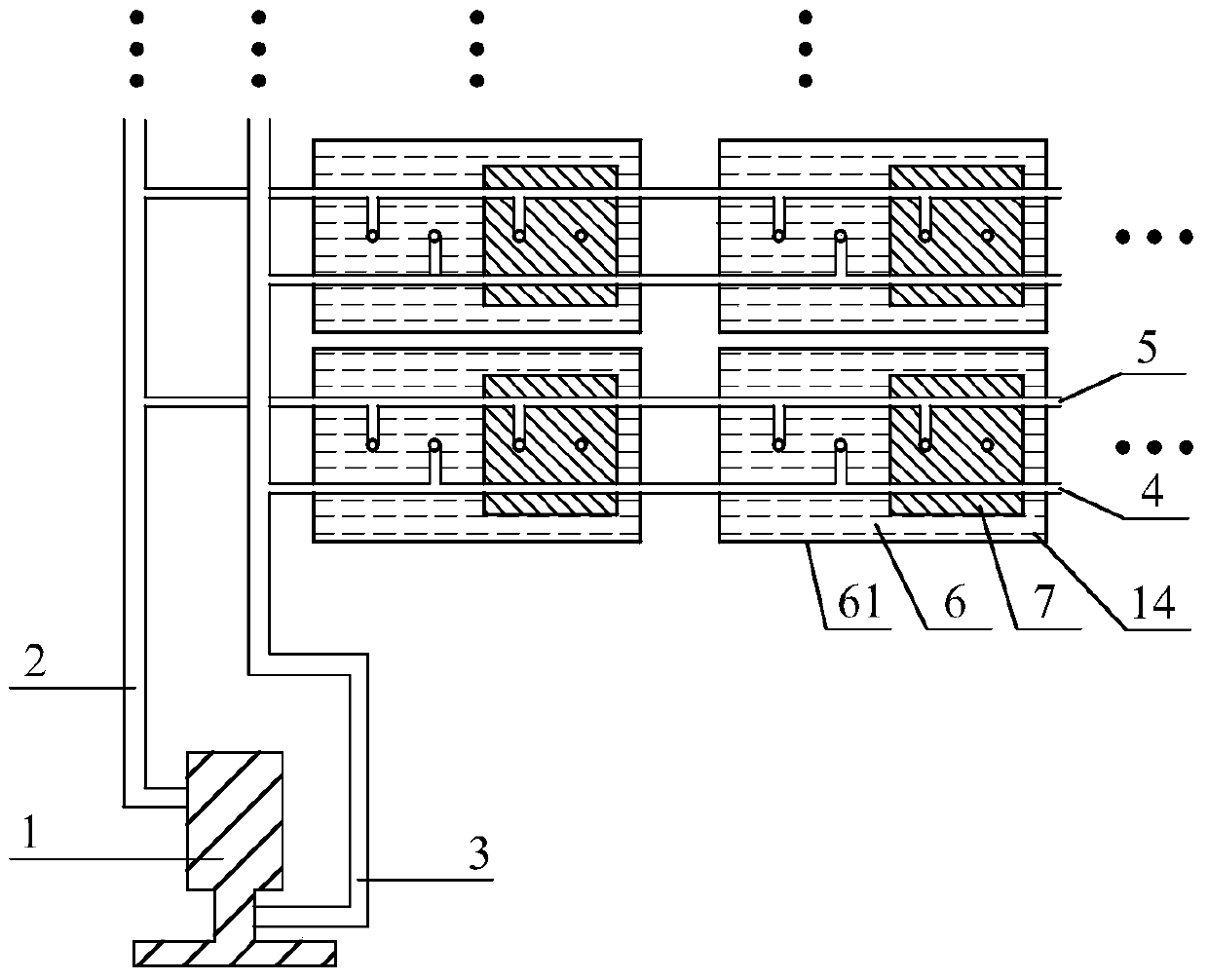

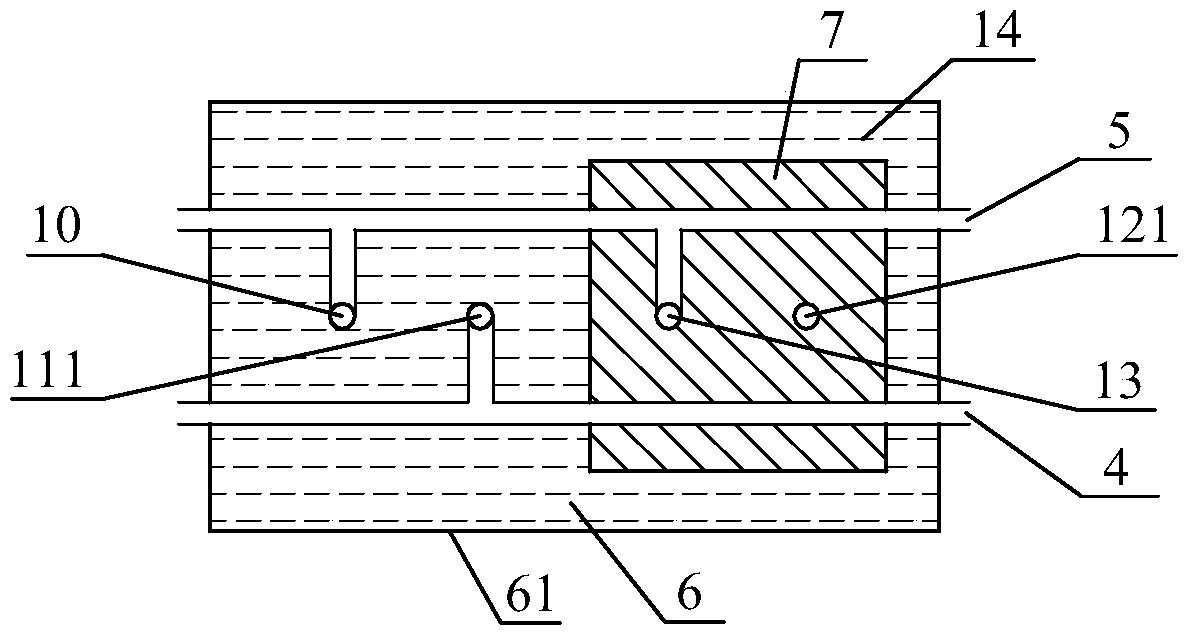

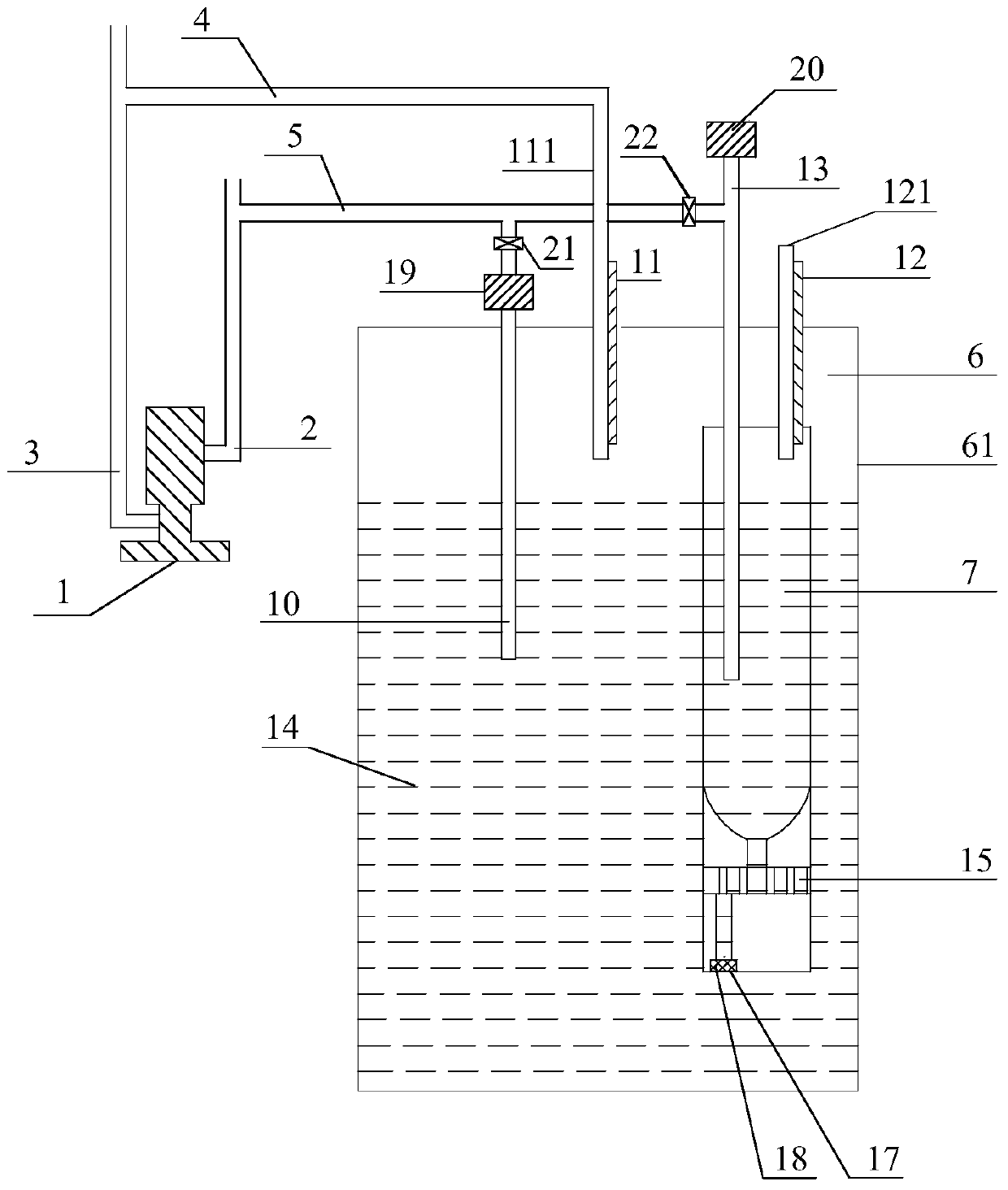

[0074] as attached Figure 1-4 Shown is a solid carbon fuel cell stack in which the parallel breathing single-plate compartment is the cathode plate compartment, including breathing device 1 and battery unit 6. Eighty groups of battery units are connected in parallel to the breathing device, and the high-voltage end of the breathing device is connected to the exhalation device. The main pipeline 2, the low-pressure end of the breathing apparatus is connected to the main suction pipeline 3, the main pipeline is connected to ten branch pipelines 5, the main pipeline is connected to ten branch pipelines 4, and the anode intake pipes of eight battery units 10 and the upper end of the cathode intake pipe 13 are connected to the exhalation branch pipe 5, and the upper ends of the anode exhaust pipe 111 of the eight battery units are connected to the suction branch pipe 4;

[0075] Each group of battery cells includes an electrolyte bin 61 and a single board bin 7, and the single boa...

Embodiment 2

[0087] This embodiment is identical with embodiment 1 basic structure, and different technical parameters are as follows:

[0088] (1) The single plate warehouse is the anode plate warehouse, and the electrolyte warehouse is the cathode plate warehouse

[0089] (2) A group of battery units are connected in parallel to the breathing apparatus, the high-pressure end of the breathing apparatus is connected to the main exhalation pipe 2, the low-pressure end of the breathing apparatus is connected to the main inhalation pipe 3, and the main exhalation pipe is connected to an exhalation branch pipe 5. The main suction pipe is connected to an suction branch pipe 4, the upper ends of the anode intake pipe 10 and the cathode intake pipe 13 of a group of battery units are connected to the exhalation branch pipe 5, and the anode exhaust pipe of a group of battery units The upper end of 111 is connected to the suction branch pipe 4;

[0090] (3) The breathing device is a turbocharger, a...

Embodiment 3

[0093] This embodiment is identical with embodiment 1 basic structure, and different technical parameters are as follows:

[0094] (1) Six hundred sets of battery units are connected in parallel on the breathing apparatus, the high-pressure end of the breathing apparatus is connected to the main exhalation pipe 2, the low-pressure end of the respiration apparatus is connected to the main inhalation pipe 3, and the main exhalation pipe is connected to ten exhalation branches. Pipeline 5, the suction main pipe is connected to ten suction branch pipes 4, the upper ends of the anode intake pipe 10 and the cathode intake pipe 13 of the sixty battery units are connected to the exhalation branch pipe 5, the anodes of the sixty battery units The upper end of the exhaust pipe 111 is connected to the suction branch pipe 4;

[0095] (2) The breathing device is a piston cylinder, and the breathing frequency of the breathing device is 2Hz.

[0096] (3) The large plate chamber and the smal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com