Composite spinneret plate

A composite spinneret and spinneret technology, which is applied in the field of spinning equipment, can solve the problem that the same board double special-shaped fiber and the same board multi-double special-shaped fiber cannot be smoothly spun and processed, and achieve smooth and stable spinning and high extrusion speed. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

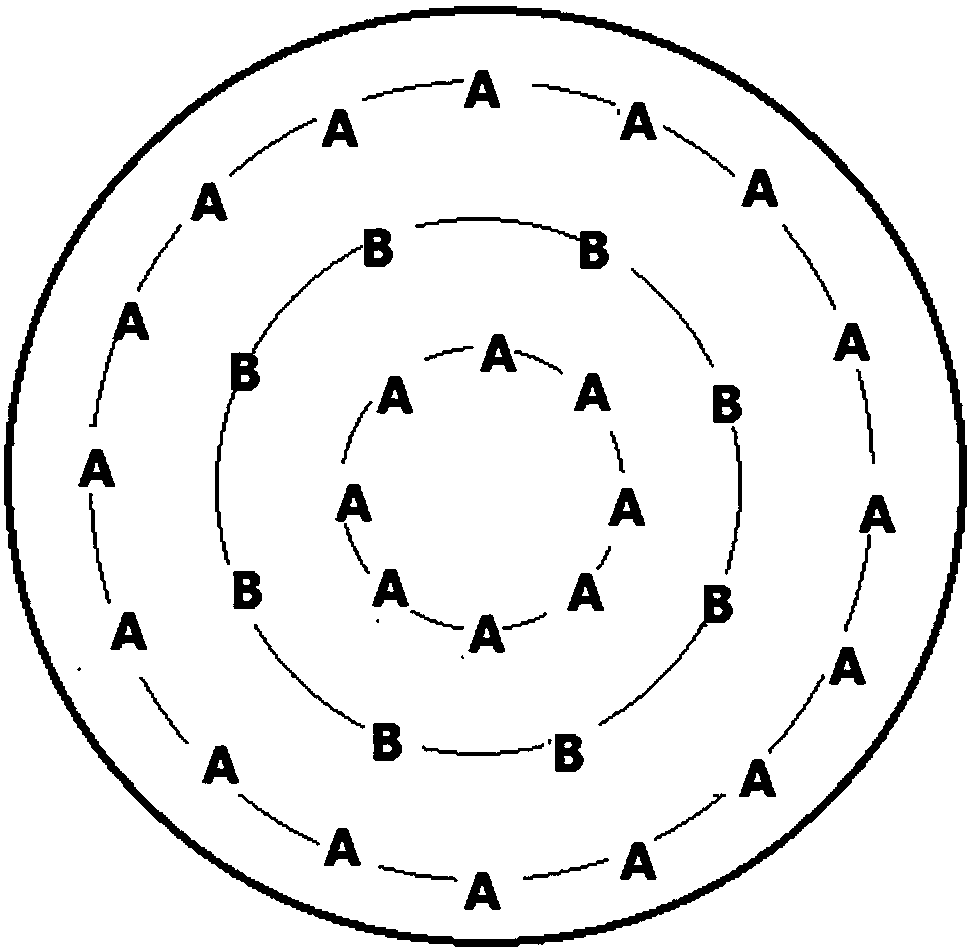

[0037] A composite spinneret on which two different spinneret holes A and B are provided at the same time. The ratio of the length of the micro-holes of the spinneret A to the spinneret B is equal to the spinneret A and the spinneret The product of the ratio of the equivalent diameter of the hole B and the coefficient K and the ratio of the consistency coefficient of the material flowing through the orifice B and the material flowing through the orifice A, the equivalent diameter is the cross-sectional area of the orifice and the cross-sectional circumference The ratio of length, where the coefficient K ranges from 0.97 to 1.03, the micropore length of spinneret A or B is 0.30 to 2.08mm, and the equivalent diameter of spinneret A or B is 0.15 to 0.52mm. Spinning hole A and spinning hole B are arranged in concentric circles on the spinneret, and the center or circumscribed circle center of spinning hole A and spinning hole B are located on concentric circles with equal interva...

Embodiment 2

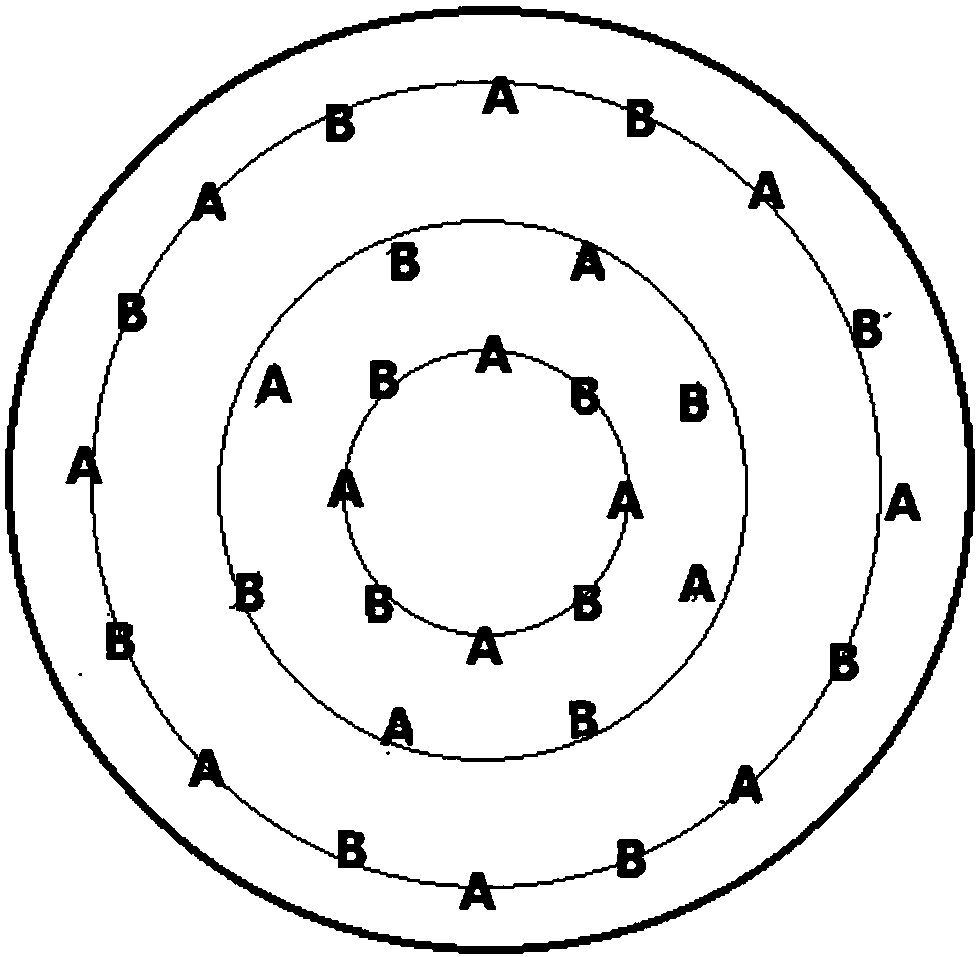

[0039] A composite spinneret. The basic structure is the same as that of Example 1. The difference is that the shape and arrangement of the spinneret holes are different. figure 2 As shown, the same ring on the spinneret contains both spin hole A and spin hole B, wherein the number ratio of spin hole A to spin hole B is 1:1, and the shape of spin hole A is triangle , The shape of the spinneret hole B is in-line.

Embodiment 3

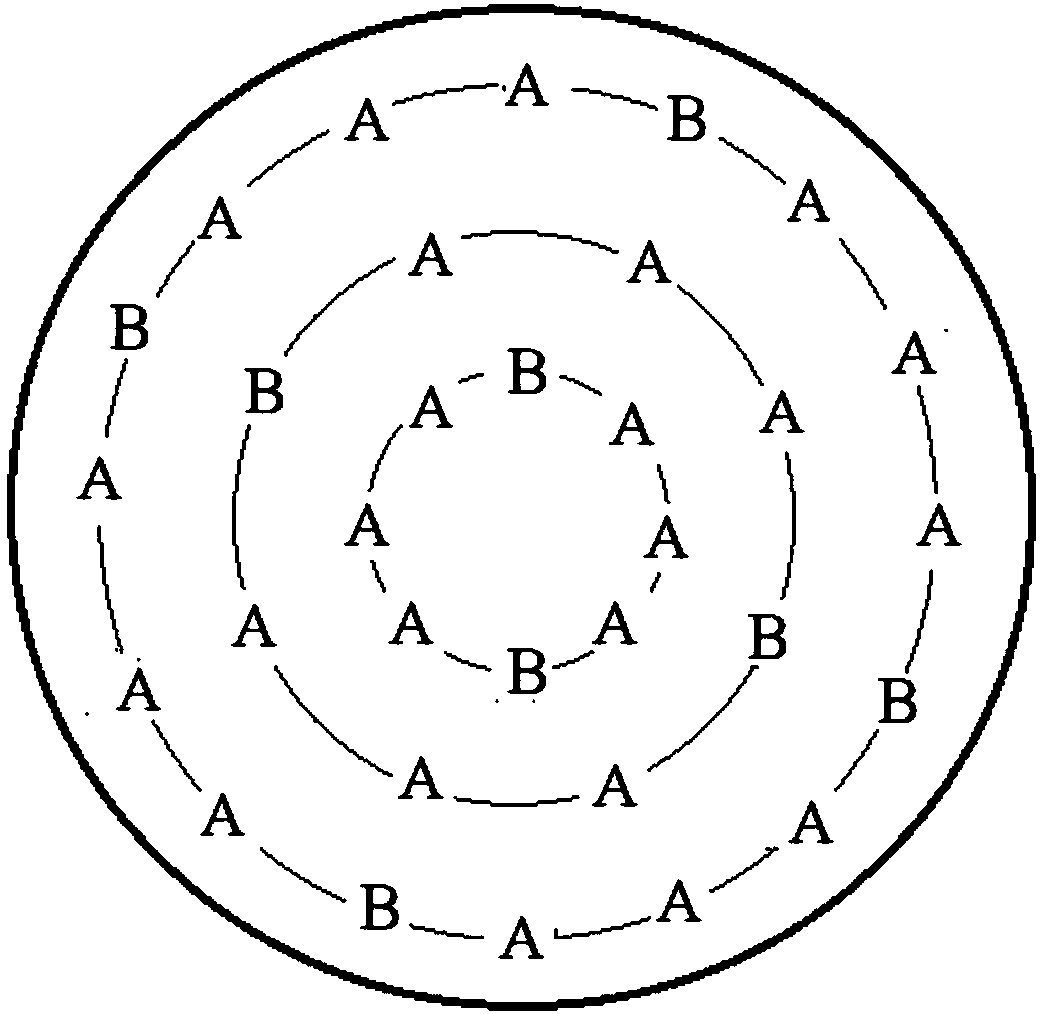

[0041] A composite spinneret. The basic structure is the same as that in Example 2. The difference is that the spinneret hole shape and arrangement are different. The schematic diagram is as follows image 3 As shown, the same ring on the spinneret contains both spin hole A and spin hole B, wherein the number ratio of spin hole A to spin hole B is 3:1, and the shape of spin hole A is five Leaf shape, the shape of the spinneret B is circular.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com