A kind of hot and humid comfortable polyester fiber dty yarn for summer and its preparation method

A polyester fiber and comfortable technology, which is applied in the field of hot and humid comfortable polyester fiber DTY yarn and its preparation in summer, can solve the problems of poor thermal and wet comfort performance, and achieve good smoothness, high oil film strength and antistatic performance strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

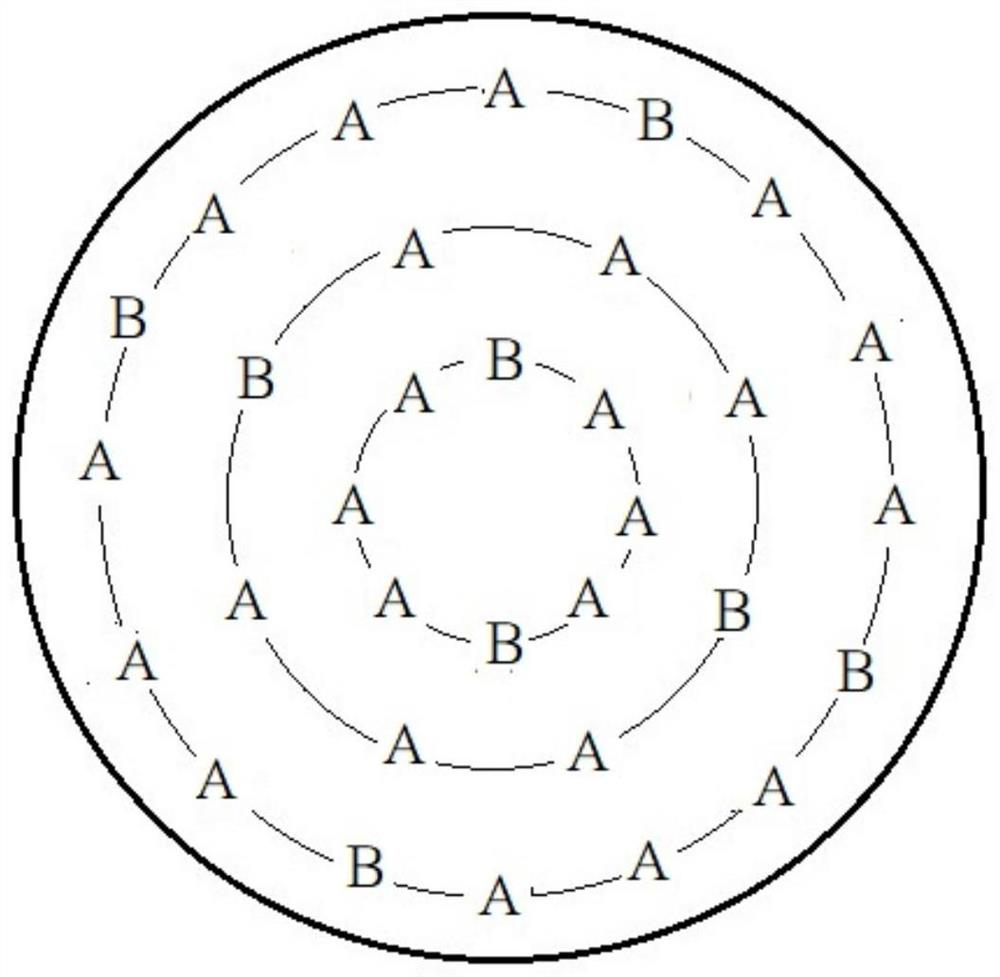

Method used

Image

Examples

Embodiment 1

[0067] A kind of preparation method of hot and humid comfortable polyester fiber DTY yarn for summer, the steps are as follows:

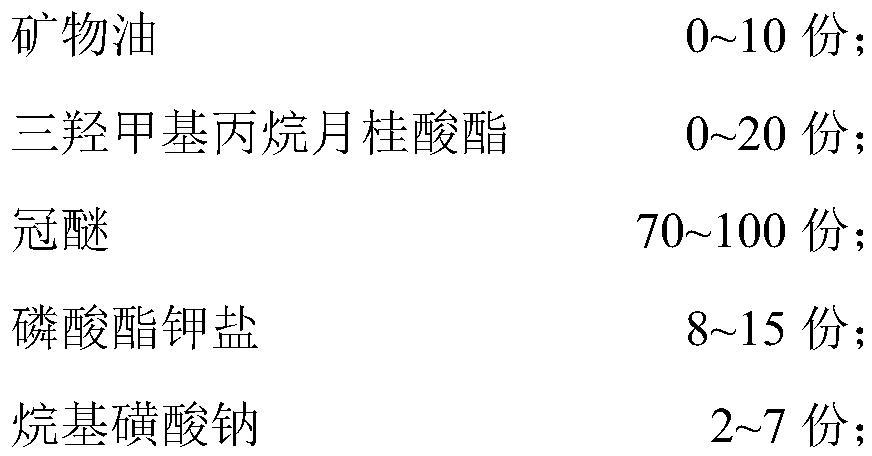

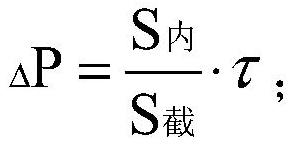

[0068] (1) Preparation of oiling agent for oiling: 2-hydroxymethyl-12-crown-4 and dodecyl phosphate potassium salt, trimethylolpropane laurate and sodium dodecyl sulfonate After mixing evenly at room temperature, add it to 9# mineral oil and stir evenly at 40°C for 1 hour to obtain an oil agent. The amount of each component added is as follows: 9# mineral oil is 2 parts; trimethylolpropane Lauric acid ester is 10 parts; 2-hydroxymethyl-12-crown-4 is 90 parts; dodecyl phosphate potassium salt is 8 parts; sodium dodecylsulfonate is 3 parts; the prepared oil The content of the crown ether is 79.6wt%, and the high temperature resistance of the oil is excellent, and the thermal weight loss is 14.5wt% after heat treatment at 200°C for 2 hours; the viscosity of the oil is low, and the kinematic viscosity 29.6mm 2 / s, the kinematic viscosity after the con...

Embodiment 2

[0074] A kind of preparation method of hot and humid comfortable polyester fiber DTY yarn for summer, the steps are as follows:

[0075] (1) Preparation of oiling agent for oiling: 15-crown ether-5 and isomeric tridecanol polyoxyethylene ether phosphate potassium salt, trimethylolpropane laurate and sodium pentadecylsulfonate in After mixing evenly at room temperature, add it to 10# mineral oil and stir evenly at 43°C for 1.5 hours to obtain the oil agent. In parts by weight, the addition amount of each component is as follows: 10# mineral oil is 2 parts; 15 parts of propane laurate; 70 parts of 15-crown-5; 10 parts of potassium isotridecyl polyoxyethylene ether phosphate; 7 parts of sodium pentadecyl sulfonate; prepared oil The content of crown ether in the agent is 67.30wt%. The high temperature resistance of the oil agent is excellent. After heat treatment at 200°C for 2 hours, the thermal weight loss is 13wt%. The viscosity of the oil agent is low. 28.1mm 2 / s, the kinem...

Embodiment 3

[0081] A kind of preparation method of hot and humid comfortable polyester fiber DTY yarn for summer, the steps are as follows:

[0082] (1) Preparation of oiling agent for oiling: mix 2-hydroxymethyl-15-crown-5 with potassium salt of tetradecyl phosphate, trimethylolpropane laurate and sodium pentadecylsulfonate After mixing evenly at room temperature, add it to 11# mineral oil and stir evenly at 48°C for 3 hours to obtain an oil agent. The addition amount of each component is as follows in parts by weight: 11# mineral oil is 8 parts; 10 parts of propane laurate; 85 parts of 2-hydroxymethyl-15-crown-5; 11 parts of potassium tetradecyl phosphate; 5 parts of sodium pentadecylsulfonate; The content of crown ether in the oil is 70.83wt%. The high temperature resistance of the oil is excellent. After heat treatment at 200°C for 2 hours, the thermal weight loss is 11wt%. The viscosity of the oil is low. Viscosity is 30.1mm 2 / s, the kinematic viscosity after the concentration is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com