A kind of hot and humid comfortable polyester fiber fdy yarn for summer and its preparation method

A polyester fiber and comfortable technology, applied in the field of summer heat-moisture comfort polyester fiber FDY and its preparation, can solve the problems of poor heat-moisture comfort performance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

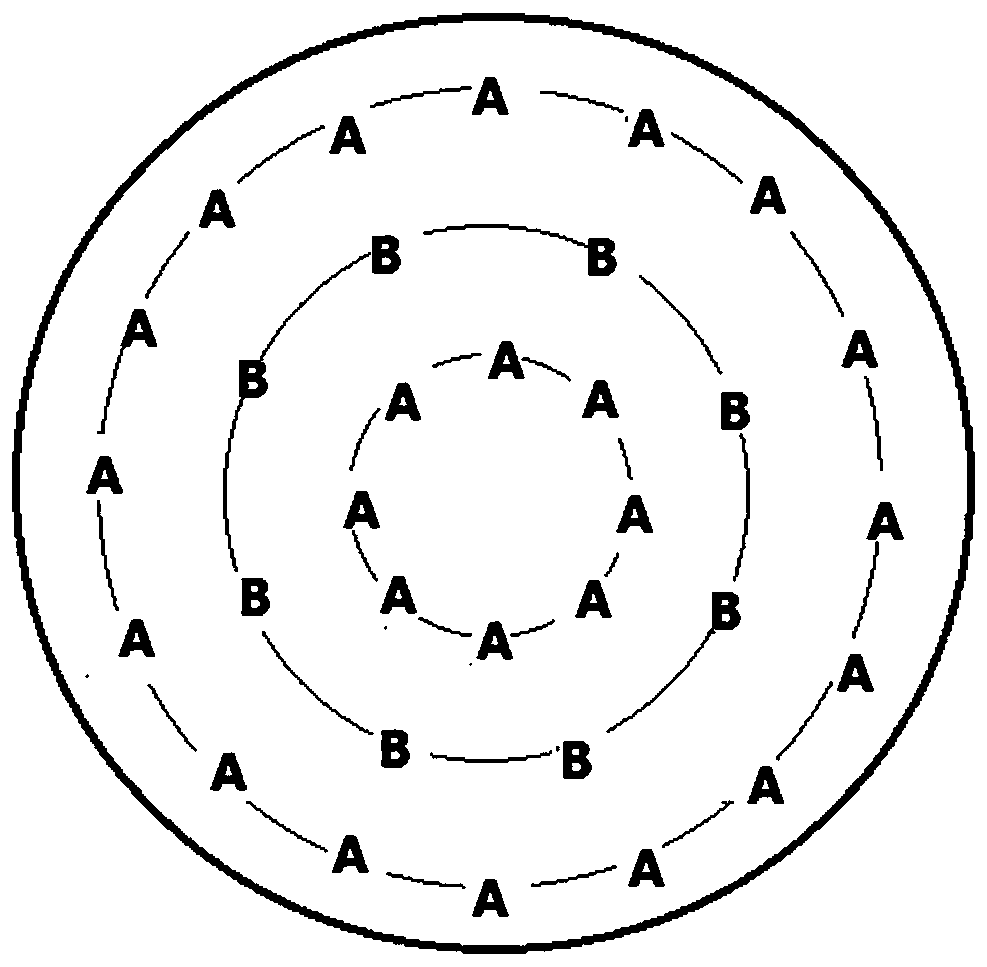

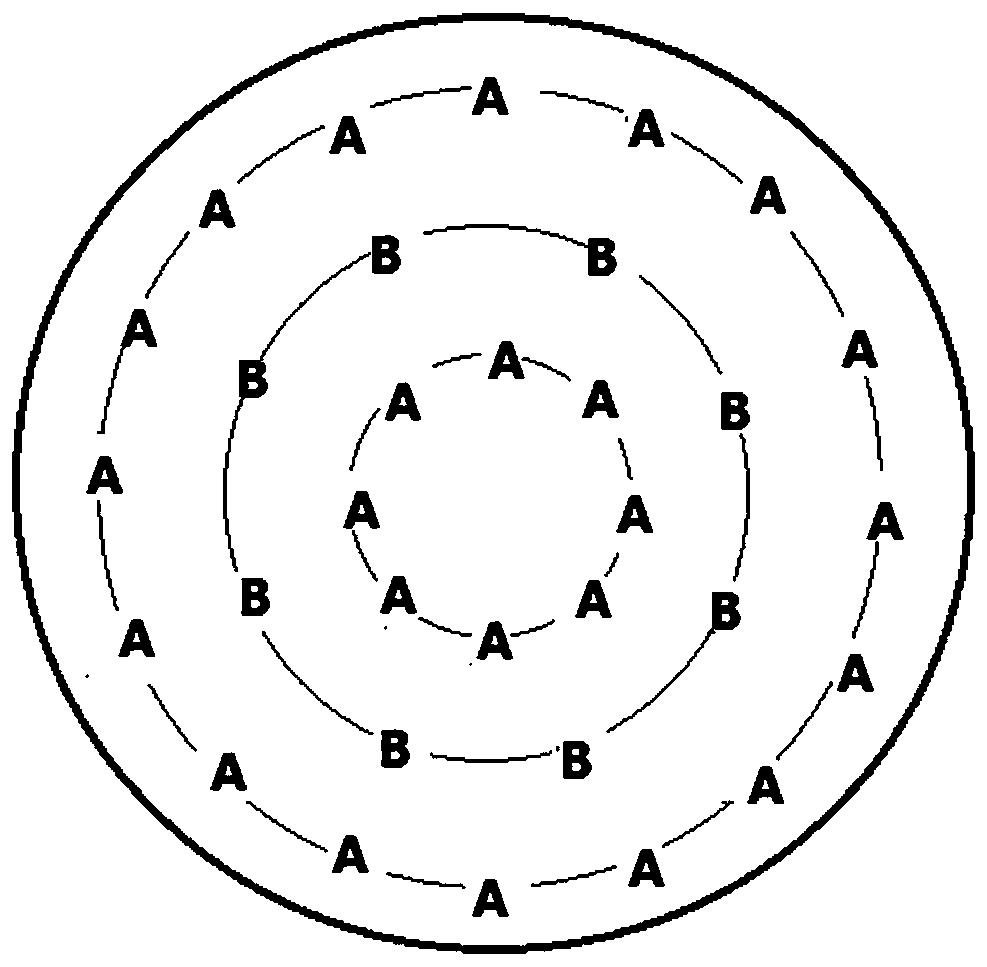

Image

Examples

Embodiment 1

[0067] A summer hot and humid comfortable polyester fiber FDY yarn, the preparation method is:

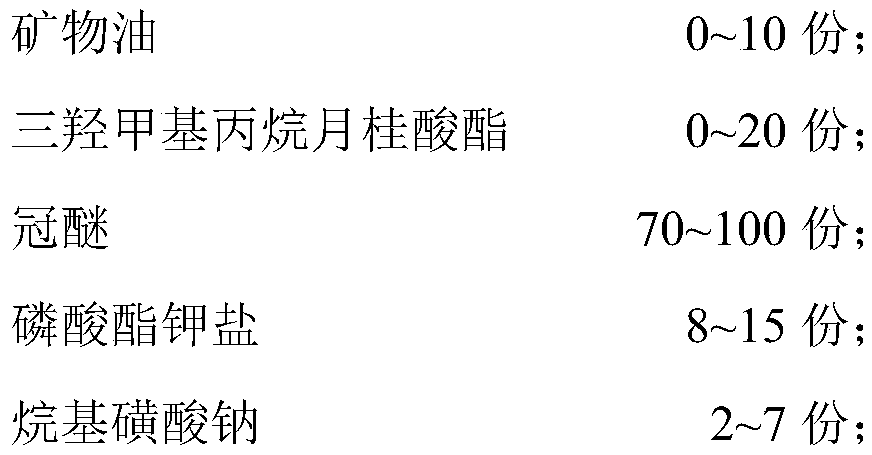

[0068] (1) preparation of oiling agent for oiling;

[0069] Mix 2-hydroxymethyl-12-crown-4 with potassium dodecyl phosphate, trimethylolpropane laurate and sodium hexadecylsulfonate at room temperature and add to 12# mineral oil and uniformly stirred at 40°C for 2.5h to obtain an oil agent; the addition amount of each component is as follows in parts by weight: 5 parts of 12# mineral oil; 95 parts of 2-hydroxymethyl-12-crown-4; 12 9 parts of potassium alkyl phosphate; 2 parts of sodium hexadecyl sulfonate. The content of crown ether in the prepared oil is 85.58wt%. The oil has excellent high temperature resistance. After heat treatment at 200°C for 2 hours, the thermal weight loss is 9wt%. The viscosity of the oil is low. When the kinematic viscosity is 29.5mm 2 / s, the kinematic viscosity after the concentration of 10wt% emulsion is configured with water is 0.93mm 2 / s, the oi...

Embodiment 2

[0075] A summer hot and humid comfortable polyester fiber FDY yarn, the preparation method is:

[0076] (1) Preparation of oiling agent for oiling; 15-crown ether-5 and isomeric tridecyl alcohol polyoxyethylene ether phosphate potassium salt, trimethylolpropane laurate and sodium dodecylsulfonate are mixed at room temperature After mixing evenly, add it to 13# mineral oil and stir evenly at 52°C for 2 hours to obtain an oil agent; in parts by weight, the addition amount of each component is as follows: 10 parts of 13# mineral oil; trimethylolpropane lauric acid 5 parts of ester; 70 parts of 15-crown ether-5; 8 parts of isomeric tridecyl polyoxyethylene ether phosphate potassium salt; 6 parts of sodium dodecylsulfonate. The content of the crown ether in the prepared oil is 70.70wt%. The high temperature resistance of the oil is excellent. After heat treatment at 200°C for 2 hours, the thermal weight loss is 13.5wt%. The viscosity of the oil is low, at (50 ± 0.01) At ℃, the kin...

Embodiment 3

[0082] A summer hot and humid comfortable polyester fiber FDY yarn, the preparation method is:

[0083] (1) Oil preparation for oiling; 2-hydroxymethyl-15-crown-5 and potassium salt of tetradecyl phosphate, trimethylolpropane laurate and sodium pentadecylsulfonate After mixing evenly at room temperature, add it to 11# mineral oil and stir evenly at 48°C for 3 hours to obtain an oil agent; in parts by weight, the addition amount of each component is as follows: 8 parts of 11# mineral oil; trimethylolpropane lauryl 10 parts of acid ester;

[0084] 2-Hydroxymethyl-15-crown-585 parts; Tetradecyl phosphate potassium salt 11 parts; Sodium pentadecylsulfonate 5 parts. The content of crown ether in the prepared oil is 70.83wt%. The oil has excellent high temperature resistance. After heat treatment at 200°C for 2 hours, the thermal weight loss is 11wt%. The viscosity of the oil is low. When the kinematic viscosity is 30.1mm 2 / s, the kinematic viscosity after the concentration is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com