Liftable steel bar processing shed with solar panel and construction method of liftable steel bar processing shed

A technology for solar panels and processing sheds, applied to roofs using tile/slate tiles, roofs using flat/curved panels, building components, etc., can solve the problem of insufficient height and overhang of steel processing sheds, difficult disassembly, waste of materials, etc. problem, to achieve the effect that is conducive to drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

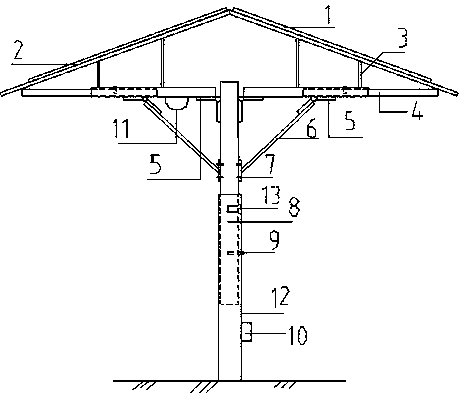

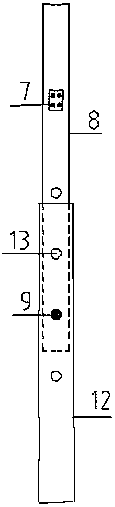

[0017] Such as figure 1 , figure 2 As shown, the present invention is a liftable steel bar processing shed with a solar panel and a construction method thereof. The liftable steel bar processing shed with a solar panel includes a bottom shed 2, a solar panel 1, a support 3, a telescopic cantilever 4, and a special composite Page 5, diagonal support 6, bolt 7, inner steel pipe 8, telescopic cantilever 4 and inner steel pipe 8 are connected by diagonal support 6, diagonal support 6 and telescopic cantilever 4 are connected by special hinge 5, diagonal support 6 and inner The steel pipes 8 are connected by bolts 7, the lighting lamp 11 is installed under the bottom shed 2, the power storage equipment 10 is installed on the outer steel pipe 12, the inner steel pipe 8 and the outer steel pipe 12 are fixedly connected by the fixing pin 9 installed in the positioning hole 13; the bottom shed 2 set the solar panel on 1

[0018] Such as figure 1 As shown, the material of the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com