Underwater vibrating system and universal transmission device thereof

A universal transmission and driving device technology, applied in elastic couplings, mechanical equipment, couplings, etc., can solve the problems of low service life, easy damage, and high requirements on tensile strength of tarpaulins, and achieve easy damage, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

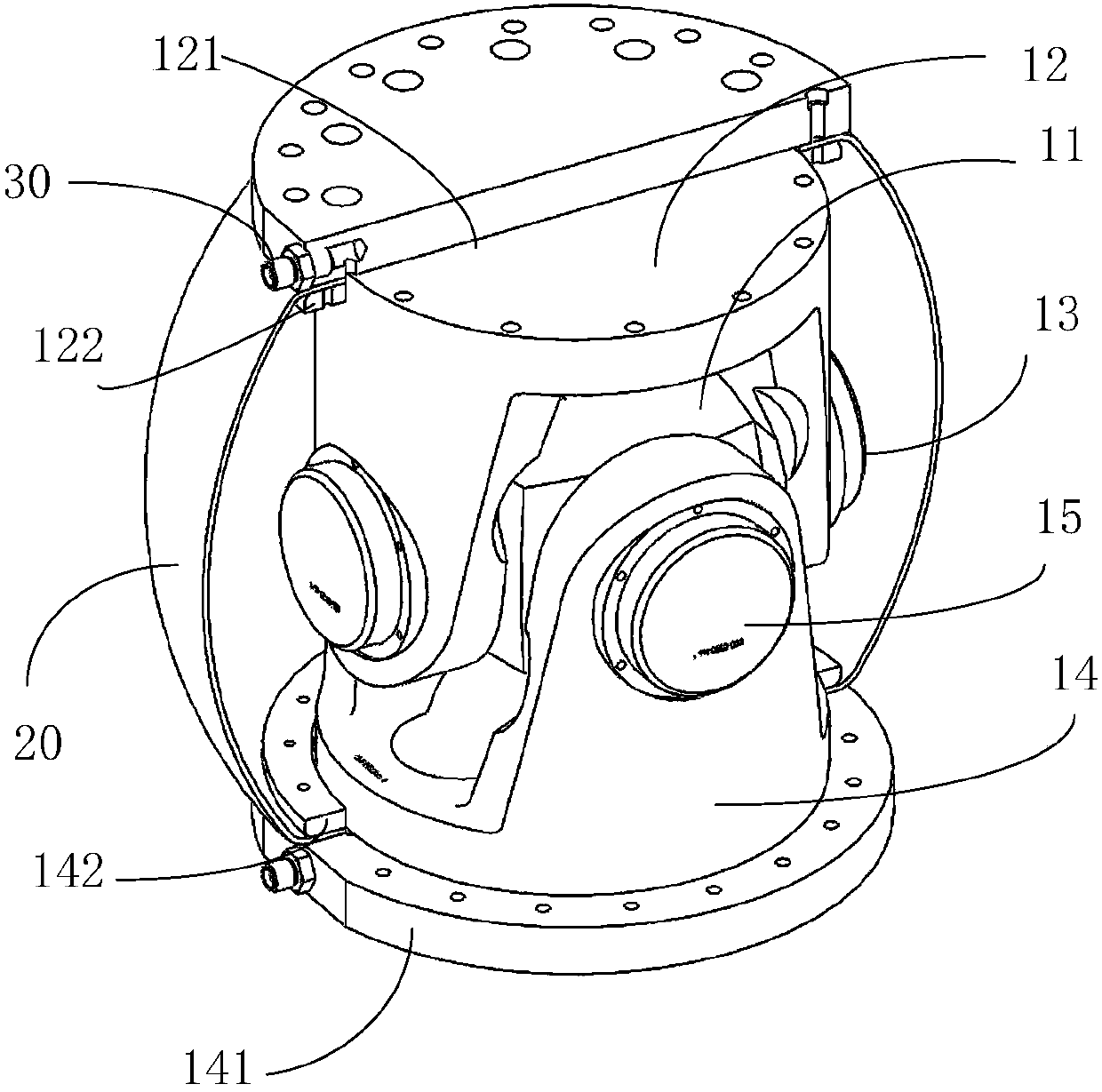

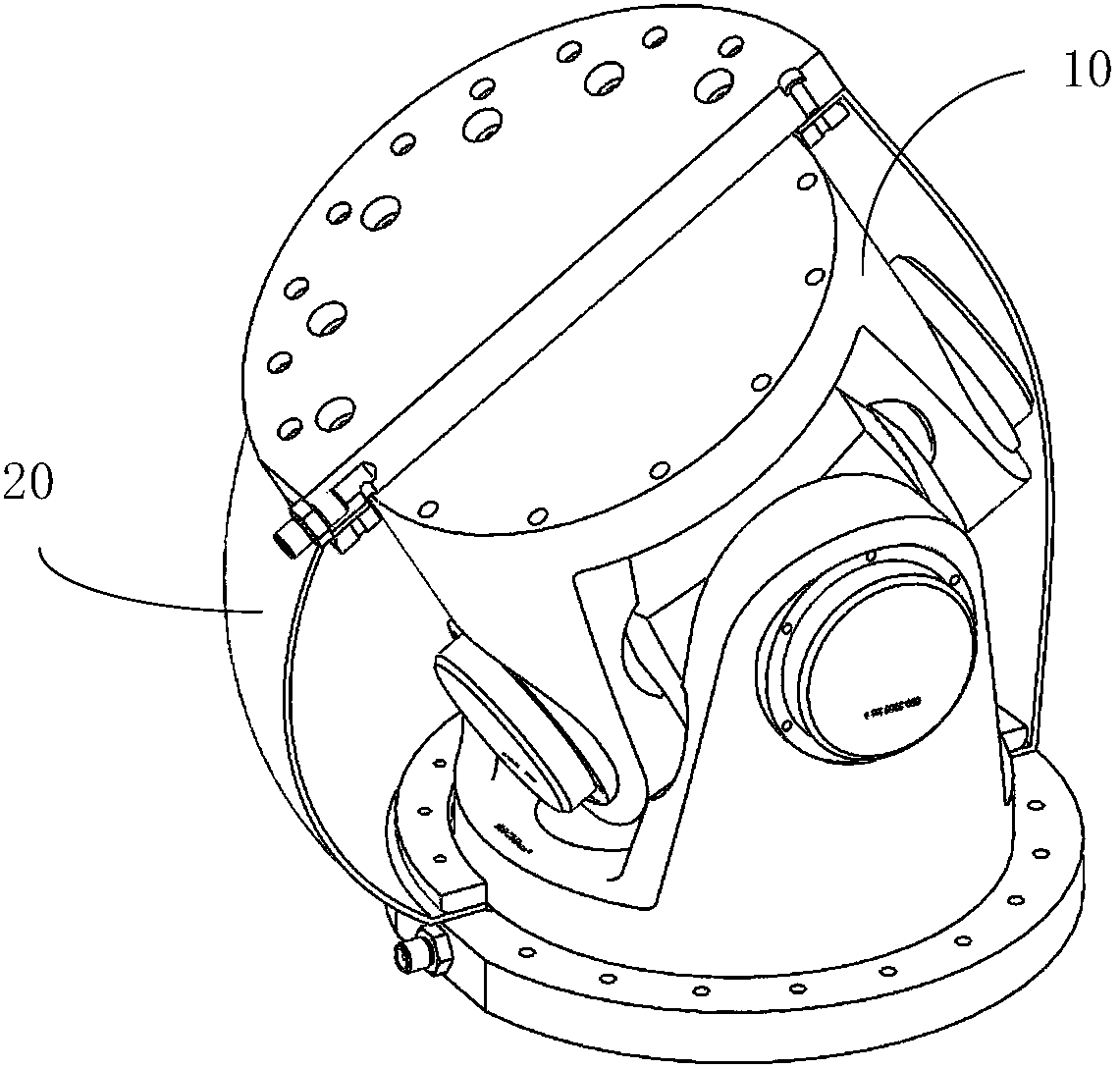

[0045] Such as figure 2 with image 3 As shown, an embodiment of the present invention proposes a universal transmission device for an underwater vibration system, which includes: a universal transmission component 10 and a flexible waterproof case 20 .

[0046]The universal transmission component 10 includes a base body 11, a first universal transmission joint 12, a first rotating shaft 13, a second universal transmission joint 14, and a second rotating shaft 15, and the first universal transmission joint 12 passes through the first rotating shaft 13 is rotationally connected with the base body 11 , and the second universal transmission joint 14 is rotationally connected with the base body 11 through the second rotating shaft 15 . A flexible waterproof sleeve 20 is on the base 11, the opening at the first end of the flexible waterproof sleeve 20 is in sealing connection with the first universal transmission joint 12, and the opening at the second end of the flexible waterpr...

Embodiment 2

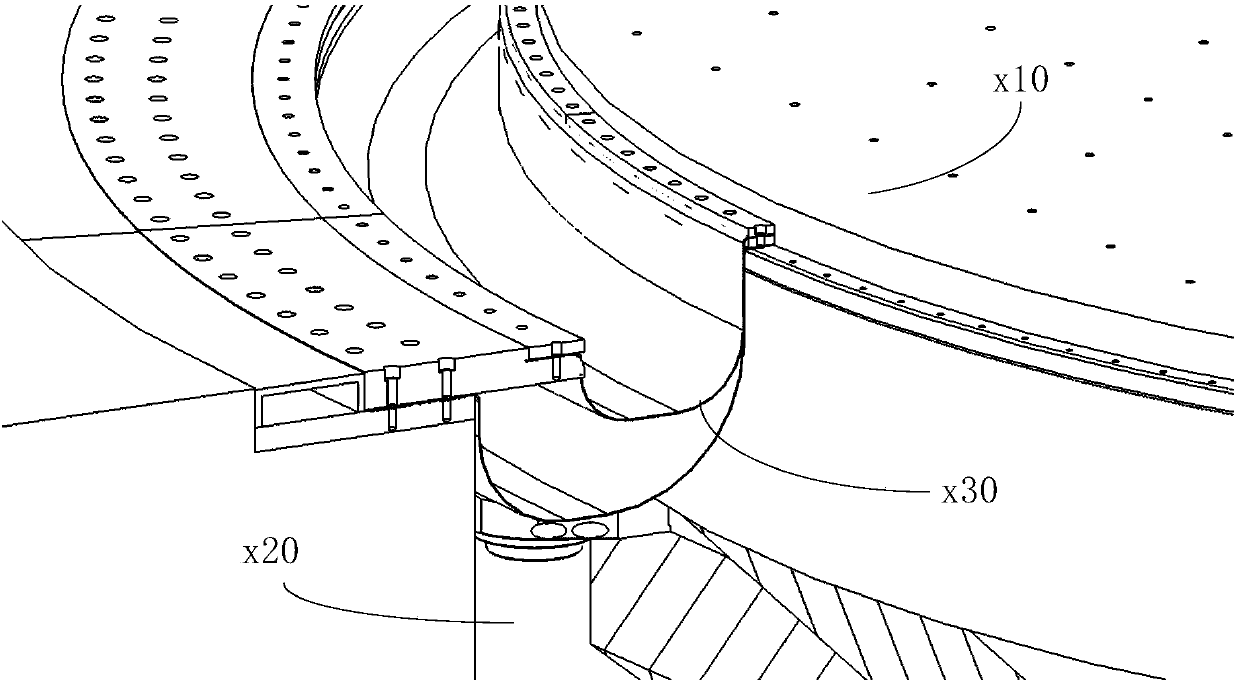

[0057] Such as Figure 4 with Figure 5 As shown, in another embodiment of the present invention, an underwater vibration system is provided. The underwater vibration system includes: a vibration table 100 , a hydraulic drive device 200 , and a multi-stage universal transmission device 300 .

[0058] The universal transmission device includes: universal transmission parts and a flexible waterproof cover. The universal transmission component includes a base body, a first universal transmission joint, a first rotating shaft, a second universal transmission joint, and a second rotating shaft, and the first universal transmission joint is rotatably connected to the base through the first rotating shaft , the second universal transmission joint is rotatably connected to the base body through the second rotating shaft. A flexible waterproof sleeve is put on the base body, the opening at the first end of the flexible waterproof sleeve is sealed and connected with the first universa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com