Coal grinding head and tail pulverized coal bin dedusting system

A technology of dust removal system and pulverized coal bin, which is applied in the field of dust removal system of coal mill head and tailing coal dust bin, can solve the problems of negative impact on clinker quality, unfavorable calcination, large increase in coal consumption, etc., achieve good economic benefits, reduce waste gas, The effect of reducing the number of coal breaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

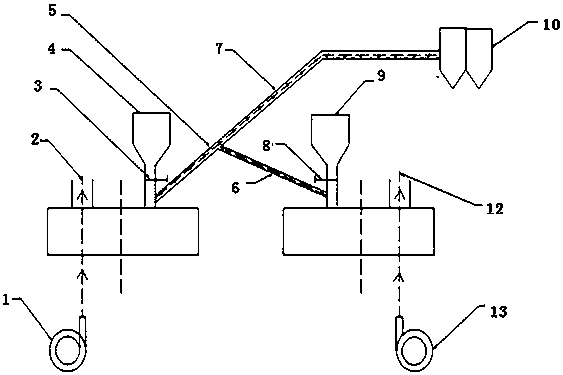

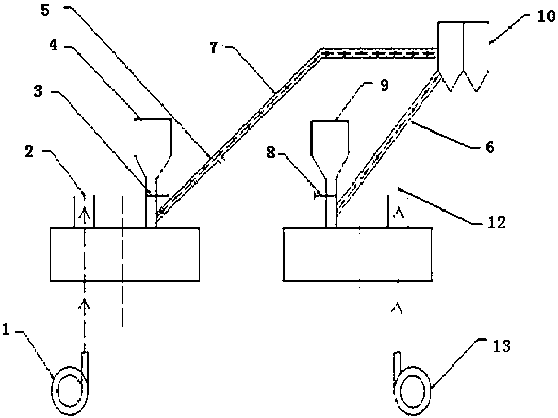

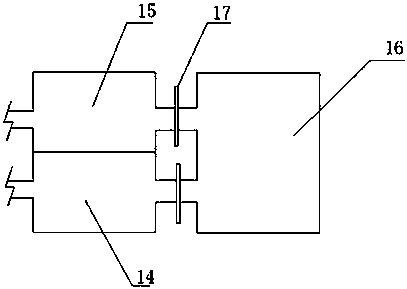

[0016] as attached figure 1 In the process, the pulverized coal is fed through the head coal bunker 9 and the tail coal bunker 4, and then is measured by the first rotor scale 3 and the second rotor scale 8, and then blown by the head coal bunker fan 13 and the tail coal bunker fan 1 respectively, and the coal The powder is blown to the burner and calciner respectively. The head coal bunker 9 and the tail coal bunker 4 have the head coal bunker pipeline 6 and the tail coal bunker pipeline 5 respectively, and are connected to the pipeline 7 together. The wind blown by the head coal bunker fan 13 and the tail coal bunker fan 1 will enter the first The fine pulverized coal before the first rotor balance 3 and the second rotor balance 8 is blown into the bag dust collector 10 . The power of the tail coal bunker fan 1 is greater than that of the head coal bunker fan 13. If the head coal bunker pipeline 6 and the tail coal bunker pipeline 5 are connected by air, the head coal bunke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com