Splash-proof automatic slurry cleaning device and automatic slurry cleaning method for water thorn head

A water thorn head and anti-sputter technology, which is applied in the field of water thorn head anti-sputter automatic slurry cleaning device, can solve the problems of large product quality stability, product quality not up to standard, product compounding is not complete, etc., to avoid Stop the machine to clean up the pulp accumulation, ensure the strength, and ensure the thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

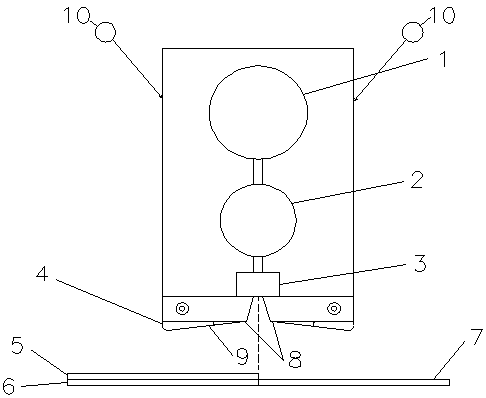

[0010] Embodiment 1: with reference to attached figure 1 . A water thorn head anti-splash automatic pulp cleaning device, including a water thorn head, the lower end plates of the anti-sputter automatic pulp cleaning boards 4 on both sides of the water thorn head are in the shape of an outer high inner low inclined plate 9 and the edge of the inclined plate 9 Adhere to edge 8 of the jet nozzle of the spunlace head. The angle α formed by the plate edge of the inclined plate 9 and the nozzle edge 8 of the water thorn head is greater than 5 degrees and less than 40 degrees (such as 5, 6, 7, 8, 9, 10, 11, 12, 13, 14 , 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39 , 40). The corner that the automatic slurry board 4 changes to the inclined panel 9 by the vertical plate is an arc corner.

Embodiment 2

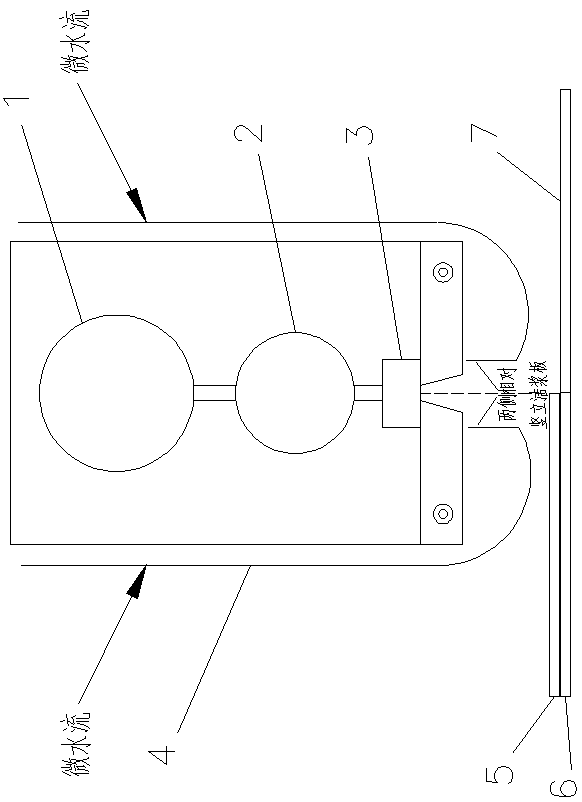

[0011] Embodiment 2: On the basis of Embodiment 1, an automatic slurry cleaning method of a water jet head anti-sputtering automatic slurry cleaning device, the water flow ejected from the water pipe 10 located on both sides of the water jet head directly acts on the slurry cleaning plate surface 4, and form a micro-water flow surface on the clean pulp plate surface 4, the micro-water flow surface flows down along the clean pulp plate surface and flows directly to the bottom of the inclined plate along the inclined plate after bypassing the arc-shaped corner at the lower end of the clean pulp plate The edge of the board, so that the wood pulp fibers splashed onto the inclined board cannot stay, and flow along the micro-water flow to the nozzle of the spunlace head, and then be washed away by the water jetted from the nozzle of the spunlace head, so that pulp deposits cannot be formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com