High-precision positioning device and high-precision positioning assisting method

A positioning device and high-precision technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of aggravated wear and can not solve the problem of low-speed and large-load precision positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described below based on the drawings.

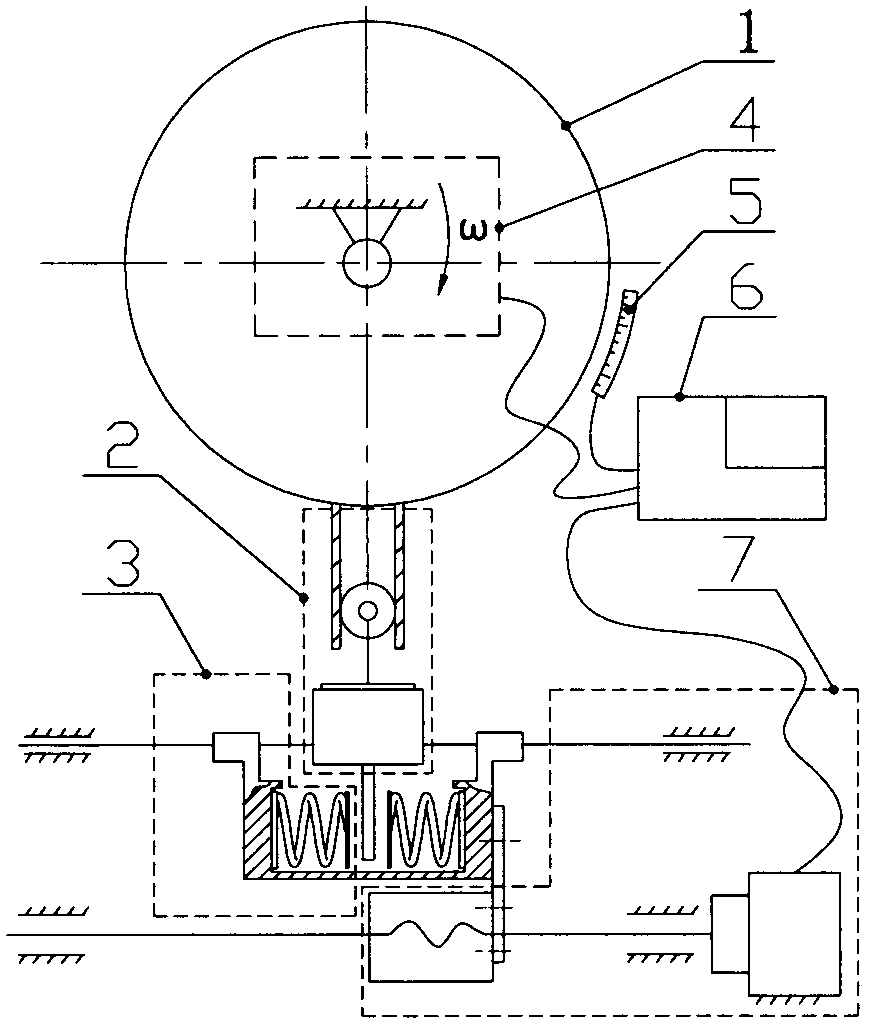

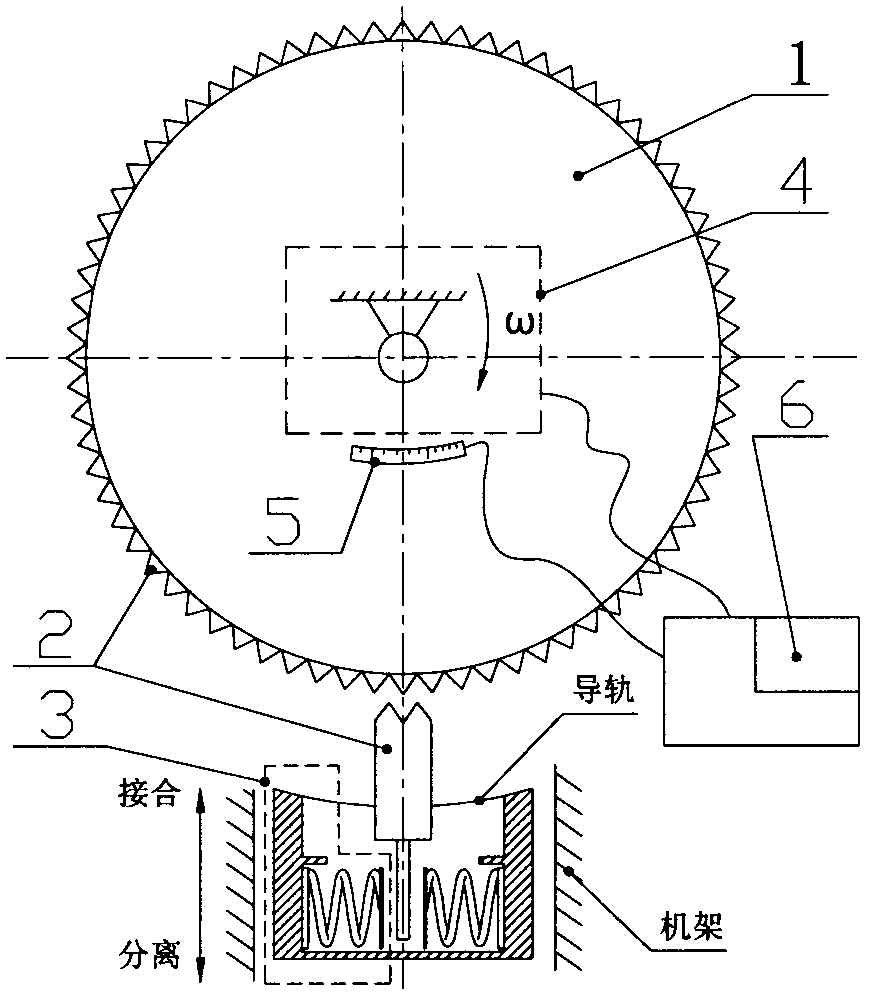

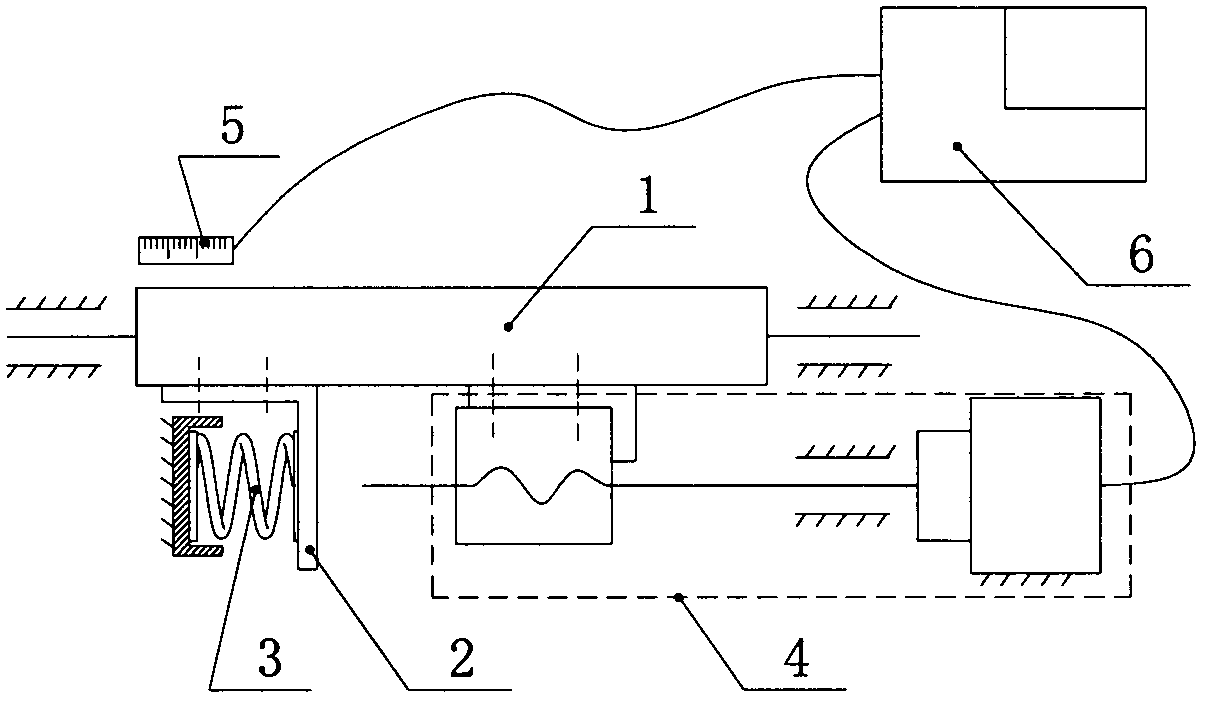

[0025] Structure of high precision positioning device

[0026] The first structural schematic diagram of a high-precision positioning device of the present invention is as follows: figure 1 As shown, it is applied to small-angle rotary indexing occasions; the second structural schematic diagram of a high-precision positioning device of the present invention is shown in figure 2 As shown, the elastic damper (3) can move radially along the worktable (1) under the action of an external force (the external force can be electromagnetic force, hydraulic pressure, etc.), and the radial movement makes the elastic damper (3) and The workbench (1) produces a clutch action, which makes the second structure applicable to large-angle rotary indexing occasions; the third structural schematic diagram of a high-precision positioning device of the present invention is as follows image 3 As shown, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com