A method for rapid construction of ultra-low interfacial tension between biosurfactant and crude oil

A biological surface and interfacial tension technology, applied in chemical instruments and methods, drilling compositions, instruments, etc., can solve problems such as difficult to study complex structure recombination behavior, difficult to guide construction work, and large differences in crude oil properties. Achieve the effect of reducing indoor screening time, high accuracy and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

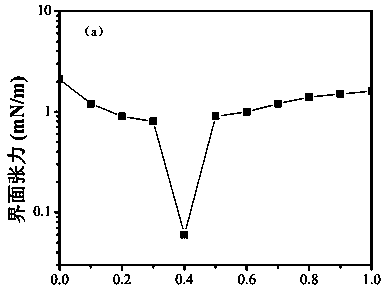

[0049] In a block H of Dongxin Oil Production Plant, the reservoir temperature is 75°C and the permeability is 650×10 -3 μm 2, the ground viscosity of crude oil is 8761mPa·s, the salinity of produced water is 55920mg / L, Ca 2+ / Mg 2+ The ion content is 3278mg / L, and the recoverable reserves are 2.5×10 4 t, the average water cut of oil wells is 95.2%. The main development contradictions of this block at this stage are: high viscosity of crude oil, active edge water, large difference in oil-water mobility ratio, and low water flooding efficiency. Aiming at the fact that the water content of the oil wells in this block increases and the output decreases, the method of the present invention is used to construct a biosurfactant composite oil displacement system to reduce the interfacial tension between the crude oil and the displacement fluid, and reduce the oil-water mobility ratio, thereby effectively reducing Comprehensive water cut of oil reservoir, enhanced oil recovery. T...

Embodiment 2

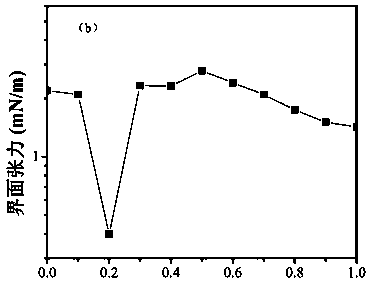

[0072] In a block G of Binnan Oil Production Plant, the reservoir temperature is 82°C and the permeability is 900×10 -3 μm 2 , the ground viscosity of crude oil is 3456mPa·s, the salinity of produced water is 10538mg / L, and the recoverable reserves are 7.5×10 4 t, the average water cut of oil wells is 96.5%. The main contradictions in the development of this block at this stage are: high viscosity of crude oil, large difference in oil-water mobility ratio, and low water flooding efficiency. Aiming at the fact that the water content of the oil wells in this block increases and the output decreases, the method of the present invention is used to construct a biosurfactant composite oil displacement system to reduce the interfacial tension between the crude oil and the displacement fluid, and reduce the oil-water mobility ratio, thereby effectively reducing Comprehensive water cut of oil reservoir, enhanced oil recovery. The specific construction steps are as follows:

[0073]...

Embodiment 3

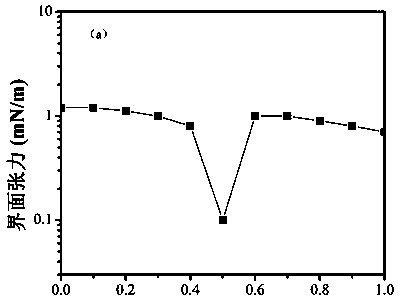

[0095] In a block L of Hekou Oil Production Plant, the reservoir temperature is 80°C and the permeability is 1200×10 -3 μm 2 , the surface viscosity of crude oil is 8756mPa·s, the salinity of produced water is 9794mg / L, and the recoverable reserves are 4.0×10 4 t, the average water cut of oil wells is 97.2%. The main development contradictions of this block at this stage are: high reservoir permeability, large difference in oil-water mobility ratio, and low water flooding efficiency. Aiming at the fact that the water content of the oil wells in this block increases and the output decreases, the method of the present invention is used to construct a biosurfactant composite oil displacement system to reduce the interfacial tension between the crude oil and the displacement fluid, and reduce the oil-water mobility ratio, thereby effectively reducing Comprehensive water cut of oil reservoir, enhanced oil recovery. The specific construction steps are as follows:

[0096] 1. On-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com