Fault prediction and health management method applied to automatic production line

An automated production line and health management technology, applied in neural learning methods, general control systems, biological neural network models, etc., to achieve the effects of reducing maintenance costs, protecting property, and reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing and embodiment

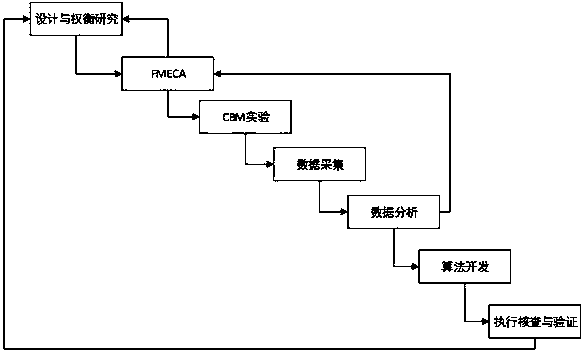

[0038] Such as figure 1 with 2 As shown, the present invention includes: design and trade-off study, FMECA analysis, CBM experiments, data collection, data analysis, algorithm development, execution check and validation. details as follows:

[0039] 1. The main role of design and trade-off research is to find the best or most balanced solution for the diagnosis and prediction of key component / subsystem failure modes in order to achieve the most ideal CBM / PHM.

[0040] 2. FMECA analysis collects previous machine failure data in order to predict failure evolution and plan existing human resources to perform maintenance operations.

[0041] 3. Perform data collection. The operating data of the equipment includes internal data and external parameters: internal data include: equipment operating frequency, error correction times, workload and other data that can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com