Automobile wire winding and sorting device

A kind of wire rod and regularization technology, which is applied in the field of automotive wire rod winding and regularizing devices, can solve the problems of irregular and smooth winding, unstable take-up tension, and insufficient flexibility, so as to achieve neat and standardized collection of cables, convenient winding of cables, and good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

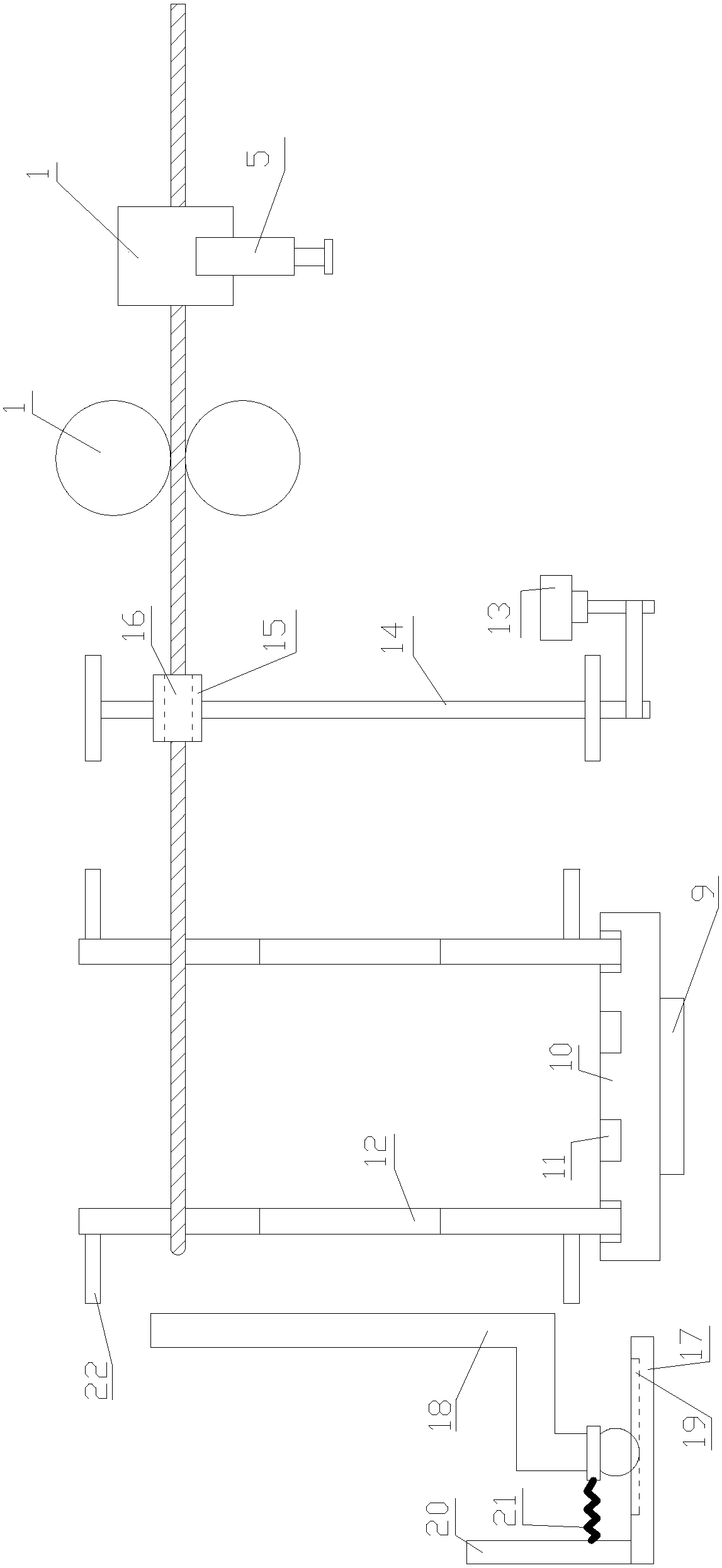

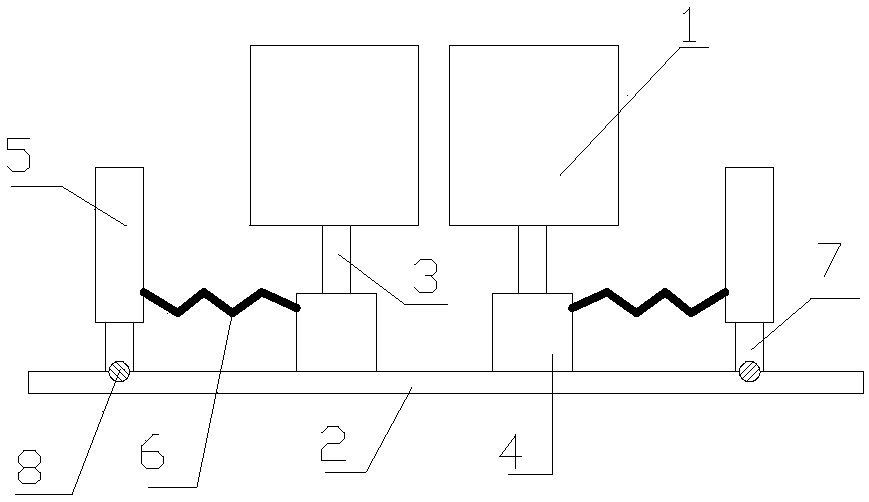

[0026] refer to figure 1 , 2 : a kind of automobile wire rod winding regularization device that the present invention proposes, comprises the roll-up mechanism that is used to roll up cable, is used to the first auxiliary mechanism that cable is rubbed, and this first auxiliary mechanism includes at least 2 rubbing units, The kneading unit includes two rollers 1, the central shafts 3 of the two rollers 1 are arranged in parallel, and a kneading channel for kneading cables is formed between the two rollers 1; the central shafts of the rollers 1 in the two kneading units The angle between 3 is not equal to 0 degrees.

[0027] Use the kneading unit to properly squeeze and knead the cable, effectively avoiding the sagging of the insulating rubber layer, and effectively ensuring the quality of the cable.

[0028] can be combined with figure 1 It is understood that this design can squeeze and knead different positions on the cable, and the effect is better; the number of specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com