A kind of red-veined semi-hard cheese and its preparation method

A semi-hard and cheese technology, applied in cheese substitutes, bacteria used in food preparation, dairy products, etc., can solve the problem that the flavor of imported cheese does not conform to the eating habits of domestic consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

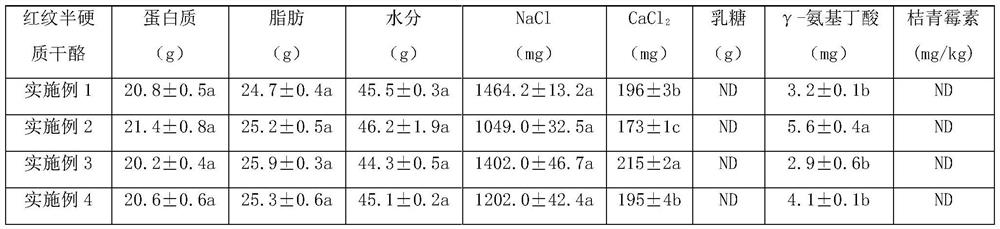

Embodiment 1

[0063] (1) Sterilize 100L raw milk at 72°C for 15s, then cool to 33°C;

[0064] (2) Add calcium chloride to the sterilized raw milk in a ratio of 9g / 100L, and stir evenly;

[0065] (3) Inoculate the lactic acid bacteria starter (Flora Danica of Co. Hansen Co., Ltd.) for fermentation. The amount of the lactic acid bacteria starter is 10U / 100L raw milk, and ferment at 33°C for 30min.

[0066] (4) Add chymosin (Danisco Company), the addition amount is 4.0g / 100L, stir slowly for 5min, then stand still for 55min to obtain curd;

[0067] (5) the curd is cut into 1cm 3 small pieces;

[0068] (6) Slowly and gently stir the curd block for 10min; then drain 20% of the whey in the container;

[0069] (7) Put the above-mentioned curd block into a mold at 15°C. After loading a layer of curd block, spread Monascus spore powder on the surface of the curd block, and then add the second layer of curd block. Repeat this process repeatedly. process until the curd block is molded. The spread...

Embodiment 2

[0077] (1) Sterilize 100L raw goat milk at 70°C for 60s, then cool to 28°C;

[0078] (2) Add calcium chloride to the sterilized raw milk at a rate of 11g / 100L

[0079] (3) Inoculate the lactic acid bacteria starter (Flora Danica of Co. Hansen Company) for fermentation, the amount of the lactic acid bacteria starter is 20U / 100L raw milk, and ferment at 28°C for 60min.

[0080] (4) Add rennet (Co. Hansen Company), the addition amount is 2.0g / 100L, stir slowly for 5 minutes, and then let it stand for 115 minutes to obtain curd;

[0081] (5) the curd is cut into 1.5cm 3 small pieces;

[0082] (6) Slowly and gently stir the curd block for 40min; then drain 40% of the whey in the container;

[0083] (7) The above-mentioned curd block is molded at 20°C. After one layer of curd block is installed, Monascus spore powder is spread on the surface of the curd block, and then the second layer of curd block is added. Repeat this process repeatedly until the curd block is molded. The sp...

Embodiment 3

[0091] (1) Sterilize 100L raw horse milk at 71°C for 45s, then cool to 30°C;

[0092] (2) Add calcium chloride to the sterilized raw milk at a rate of 10g / 100L

[0093] (3) Inoculate the lactic acid bacteria starter (MM100 starter from Danisco) for fermentation, the amount of the lactic acid bacteria starter is 15U / 100L raw milk, and ferment at 30°C for 45min.

[0094] (4) Add rennet (Danisco Company), the addition amount is 2.5g / 100L, stir slowly for 5min, then stand still for 75min to obtain curd;

[0095] (5) the curd is cut into 1.2cm 3 small pieces;

[0096] (6) Slowly and gently stir the curd block for 30min; then drain 30% of the whey in the container;

[0097] (7) The above-mentioned curd block is molded at 18°C. After one layer of curd block is installed, Monascus spore powder is spread on the surface of the curd block, and then the second layer of curd block is added. Repeat this process repeatedly until the curd block is molded. The spreading scope of red yeast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com