Wall surface self-adaptive four-caterpillar wall climbing robot

A wall-climbing robot and four-track technology are applied in the field of wall-climbing robots and wall-climbing robots with four-track self-adaptive wall-climbing obstacles. , Simple structure, stable adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

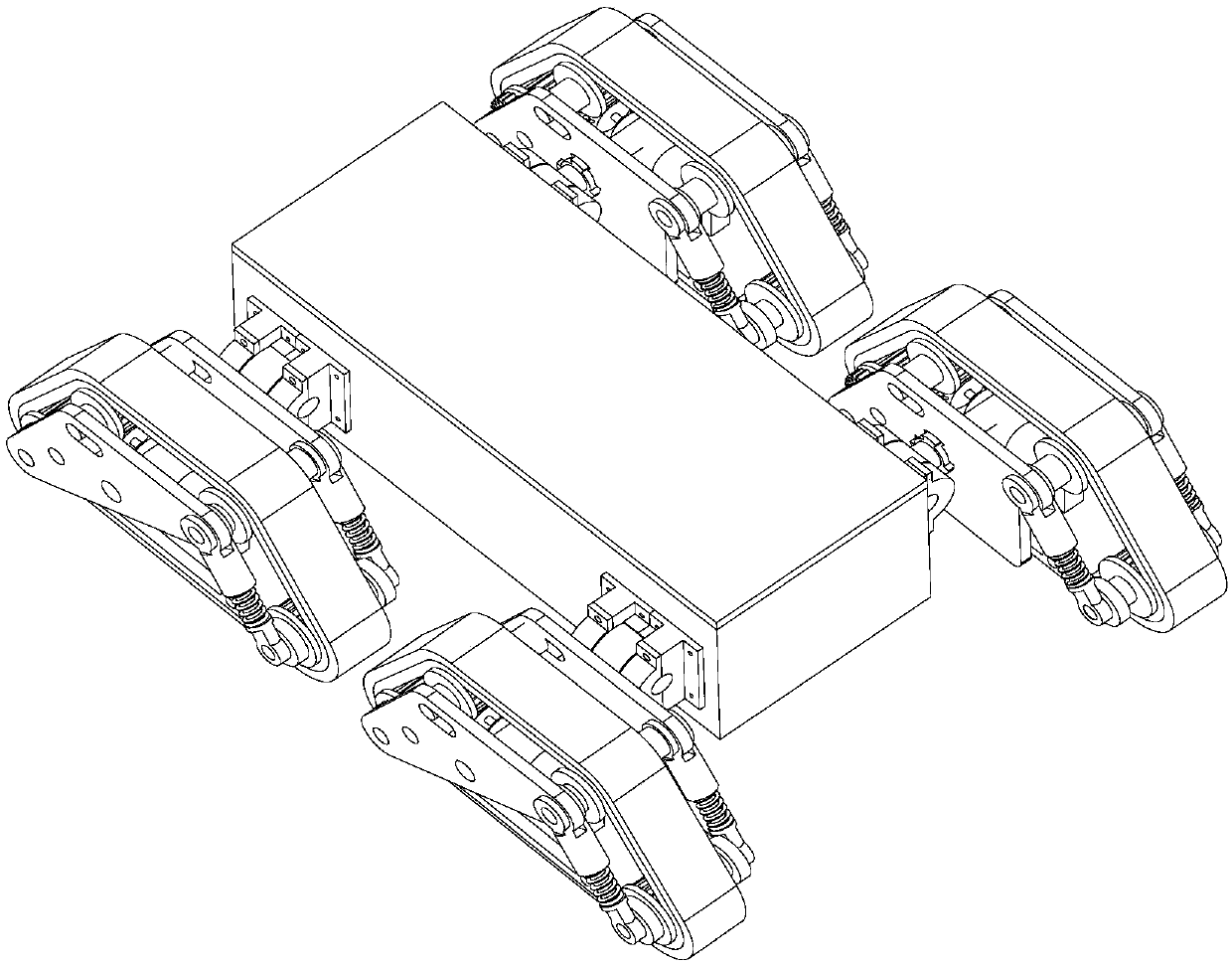

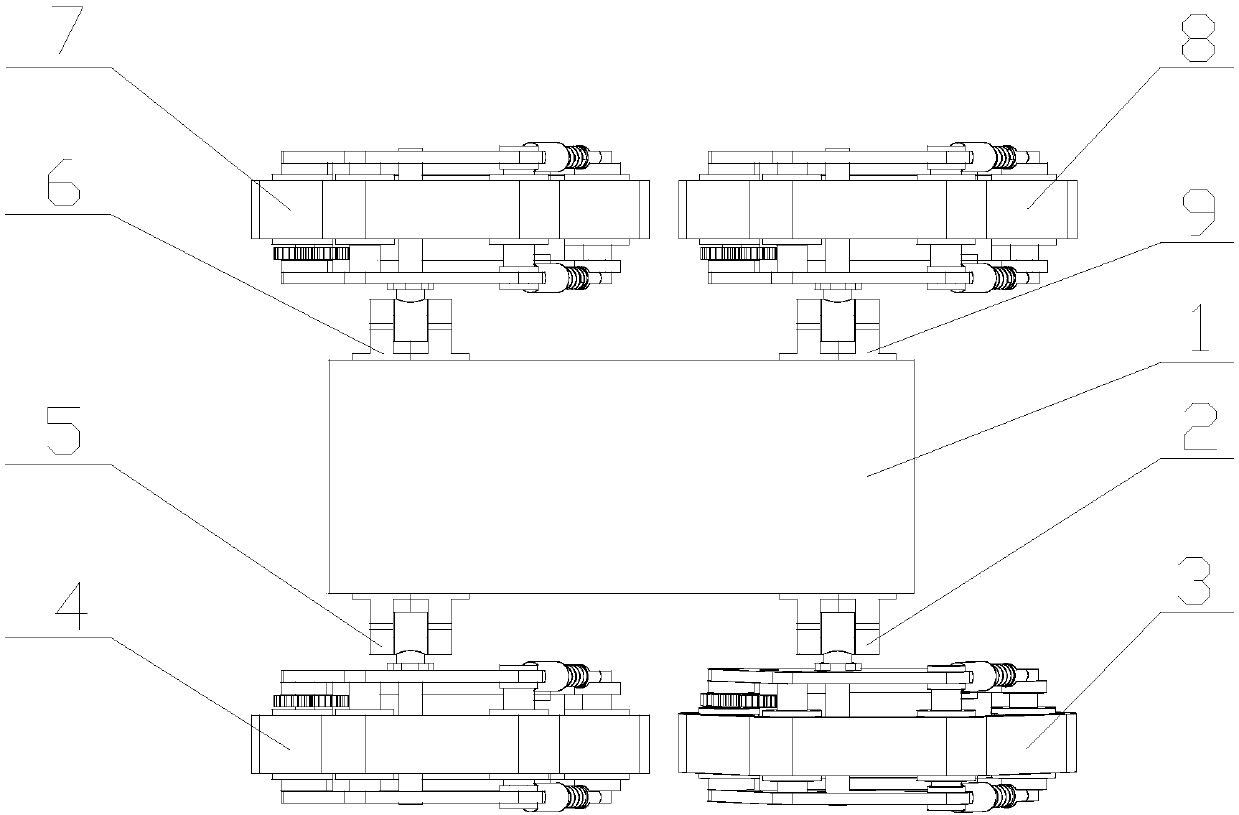

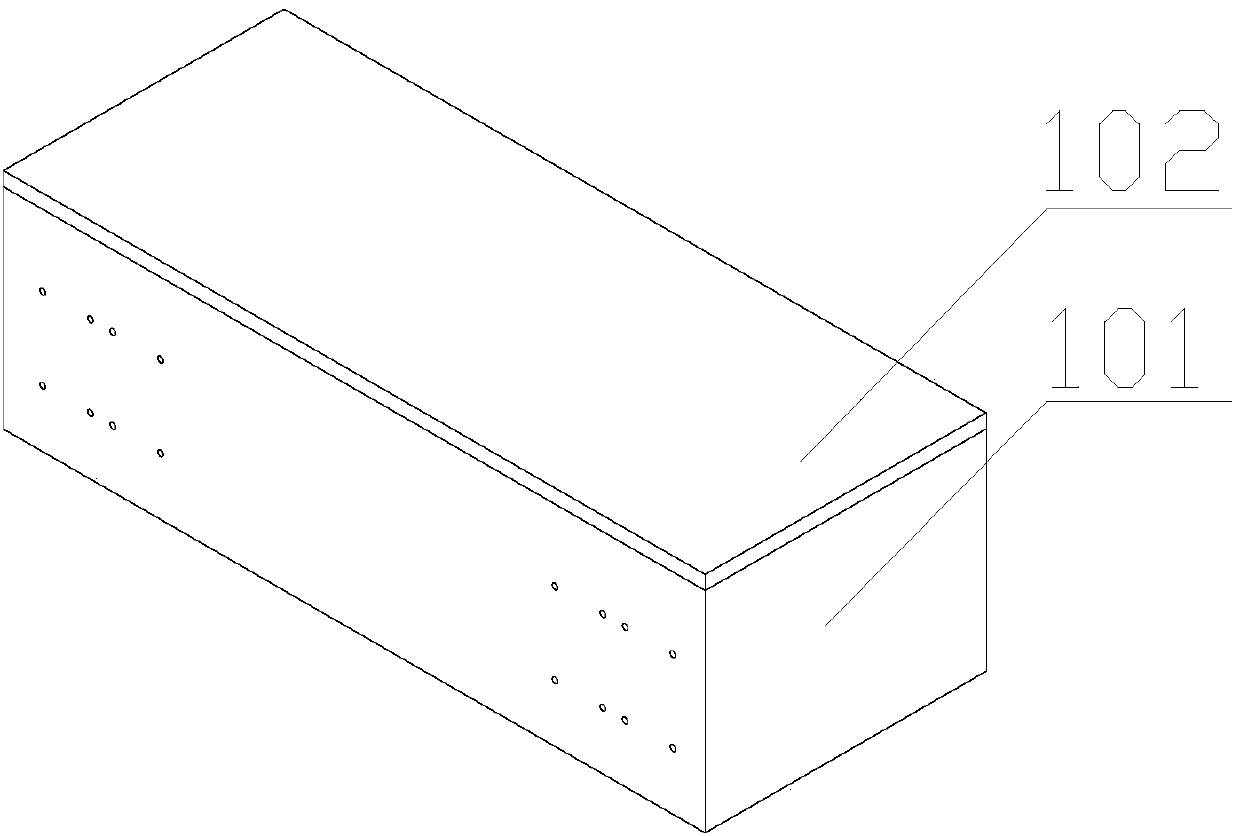

[0032] An adaptive wall-climbing robot with four crawlers, such as figure 1 and figure 2 As shown, it includes four mutually independent car body modules and an intermediate platform 1, and the four mutually independent car body modules are respectively a left front car body module 8, a left rear car body module 7, a right front car body module 3, a right The rear body module 4 and the four body modules have the same structure and are symmetrically arranged around the center platform 1 . The body modules on the left and right sides have two degrees of freedom of rotation relative to the middle platform 1 . The four car body modules are connected to the middle platform 1 through four limit joints with two degrees of freedom. The four limit joints are the front right limit joint 2, the rear right limit joint 5, and the rear left limit joint. J...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com