High-temperature and high-pressure hot blast stove mixing coal with gas

A high temperature and high pressure, hot blast stove technology, applied in air heaters, fluid heaters, gas fuel burners, etc., can solve the problems of flue gas failing to meet environmental protection requirements, many exhaust gas treatment equipment, and insufficient combustion, achieving structural Simple, reasonable design, and the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

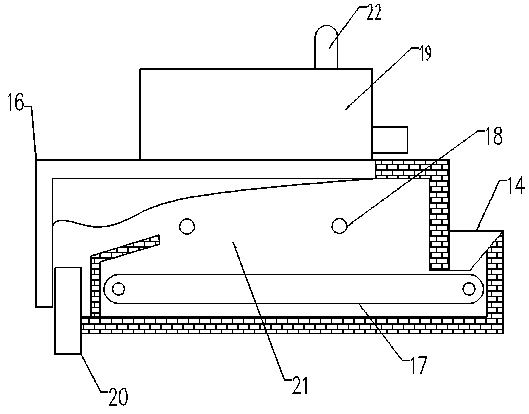

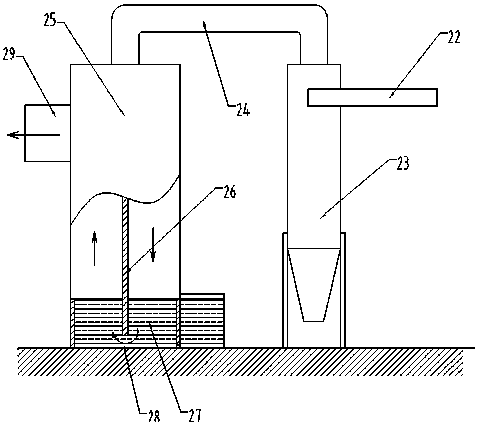

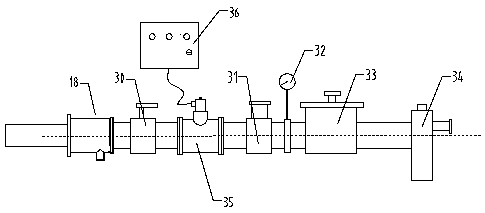

[0027] Examples such as Figure 1-4 As shown, a high-temperature and high-pressure hot blast stove mixed with gas belt coal includes a furnace body 16. A furnace 21 is arranged inside the furnace body 16. A fire grate 17 is arranged at the bottom of the furnace 21. Both sides of the furnace 21 are close to the position above the fire grate 17. Two natural gas jet combustion devices 18 are respectively arranged at a certain distance, and each natural gas jet combustion device 18 includes a position fixedly installed on the outside of the furnace body 16 near the top of the fire grate 17 respectively.

[0028] One end of the furnace body 16 is provided with an upper hopper 14 close to the position above the fire grate 17 , and the upper hopper 14 transports the fuel to the fire grate 17 .

[0029] A slag extractor 20 is provided at the end of the bottom of the furnace 21 along the direction of the fuel, and the slag extractor 20 discharges the completely burned waste slag.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com