Calibration bench for calibration of pressure transmitter

A technology of transmitter and calibration bench, applied in the direction of force/torque/work measuring instrument calibration/test, instruments, measuring devices, etc., can solve the problem of difficult vertical placement of the transmitter, and reduce external interference The influence of factors, the effect of convenient installation and reasonable arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

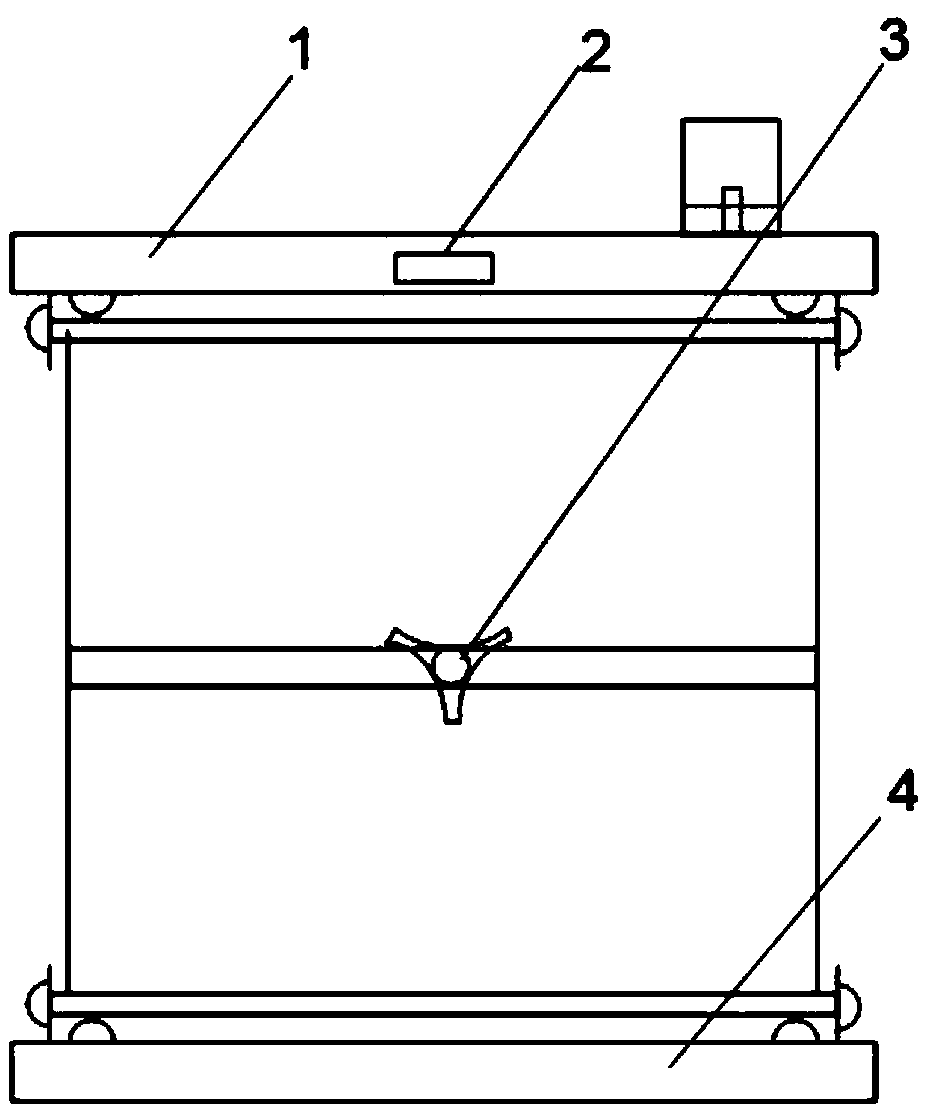

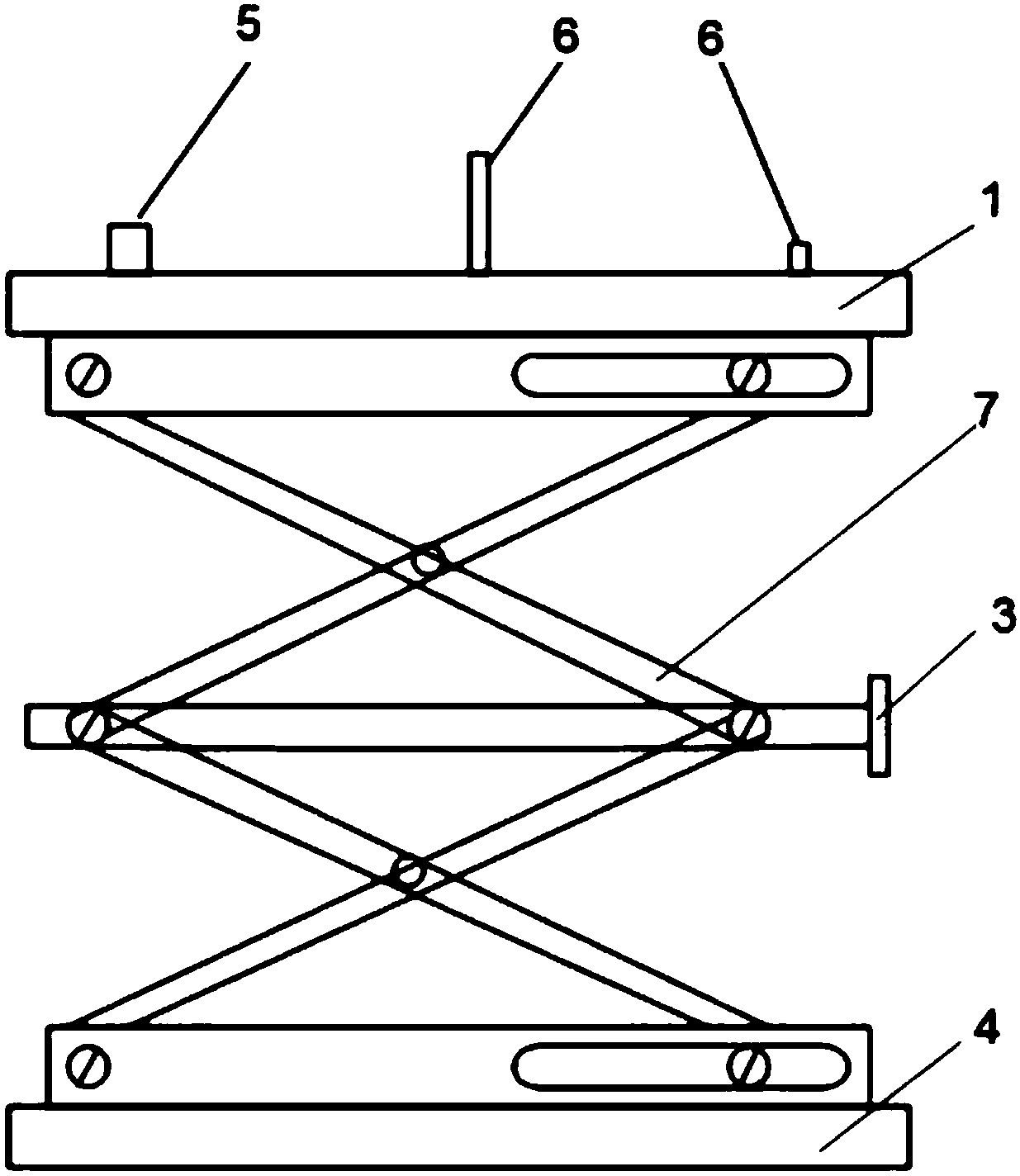

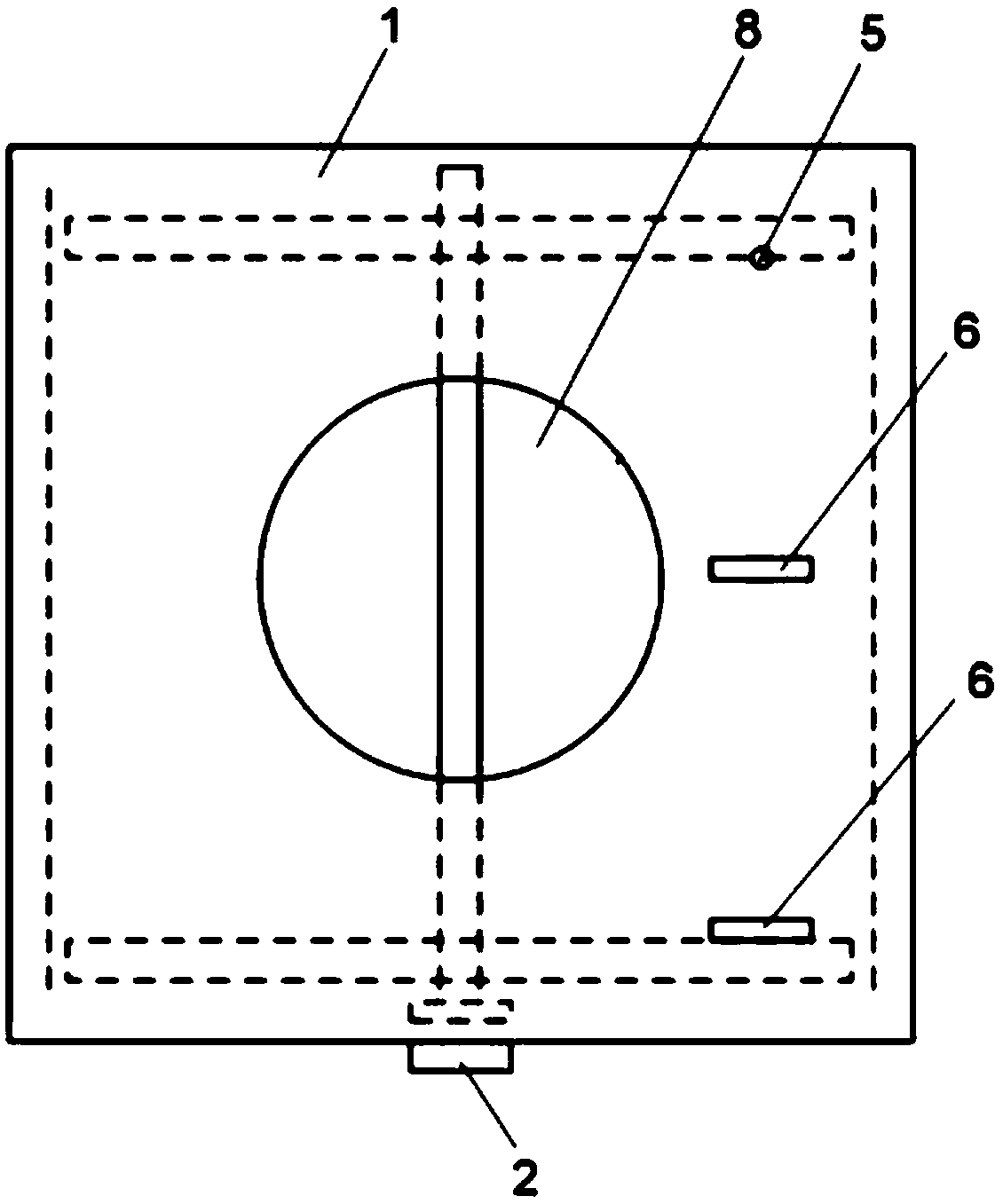

[0017] A calibration bench for pressure transmitter verification, such as Figure 1 to Figure 3 As shown, it includes a table top 1, a base 4 and a lifting frame 7. The upper and lower ends of the lifting frame are installed on the table top and the base, and a buckle 2 is installed on the side of the table top to fix the pressure transmitter. A lifting handle 3 is provided in the middle of the lifting frame to adjust the stretching degree of the lifting frame, and then adjust the height of the table top. There is an installation groove 8 for placing the pressure transmitter to be calibrated in the center of the table, and a nut 5 for installing a standard device (such as an intelligent digital pressure calibrator) and a nut for installing a hand operator are arranged beside the installation groove The card station 6 realizes the reasonable ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com