Air conditioner compressor tubing vibration reliability evaluation method

A compressor and reliability technology, applied in computer-aided design, special data processing applications, instruments, etc., can solve problems such as difficulty in comprehensively detecting piping stress, make up for test and test defects, reduce fatigue fracture risk, and improve vibration reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

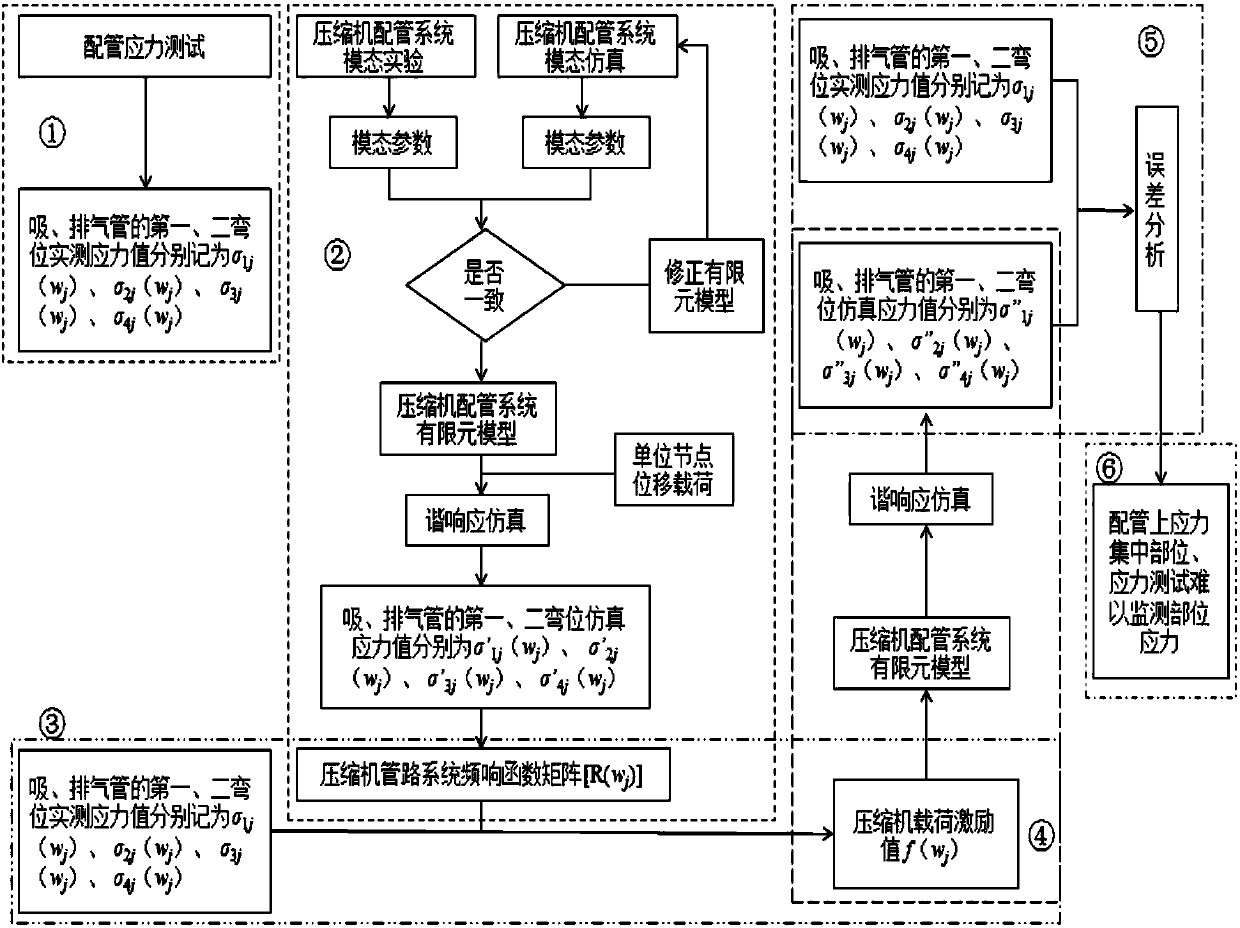

[0065] Such as figure 1 As shown, the air-conditioning compressor piping vibration reliability evaluation method in this embodiment includes the following steps:

[0066] In the first step, through the stress test, the stress values of the first and second bending positions of the suction and exhaust pipes of the inverter air conditioner in the stable operation state of each frequency point are obtained, respectively denoted as σ 1j (w j ), σ 2j (w j ), σ 3j (w j ), σ 4j (w j ), where j is the number of compressor operating frequency points. This part is the dynamic response in the classification of vibration problems.

[0067] The second step is to conduct modal experiments on the air conditioner compressor piping first, and obtain its first 20 order modal parameters, mainly the natural frequency w i (1≤i≤20), and then conduct modal simulation analysis on the air conditioner compressor distribution piping system, and obtain the first 20 modal parameters, mainly the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com