Welding method for cantilever structure with rib plates

A welding method and ribbed plate technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems that affect the overall quality and performance of the product, difficult to guarantee dimensional accuracy, deformation of structural components, etc., to reduce the risk of fatigue fracture , Reduce welding deformation, reduce the effect of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

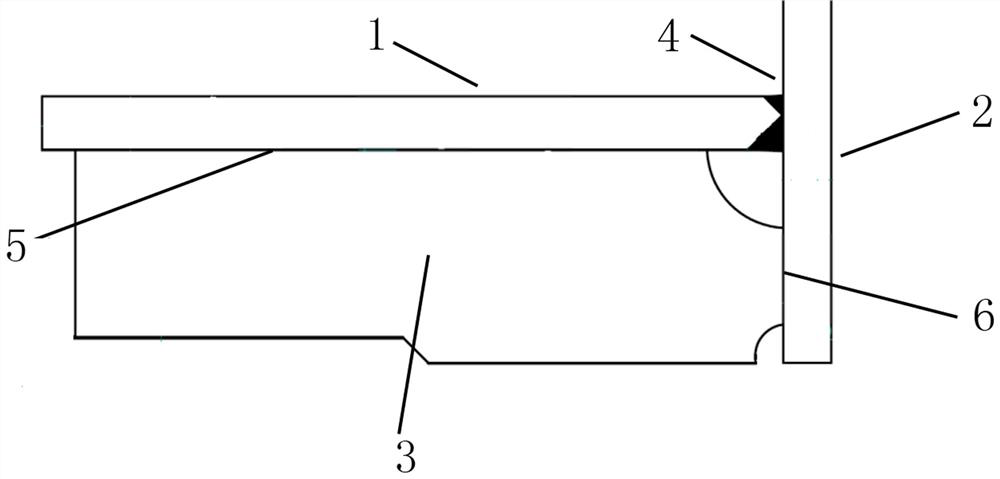

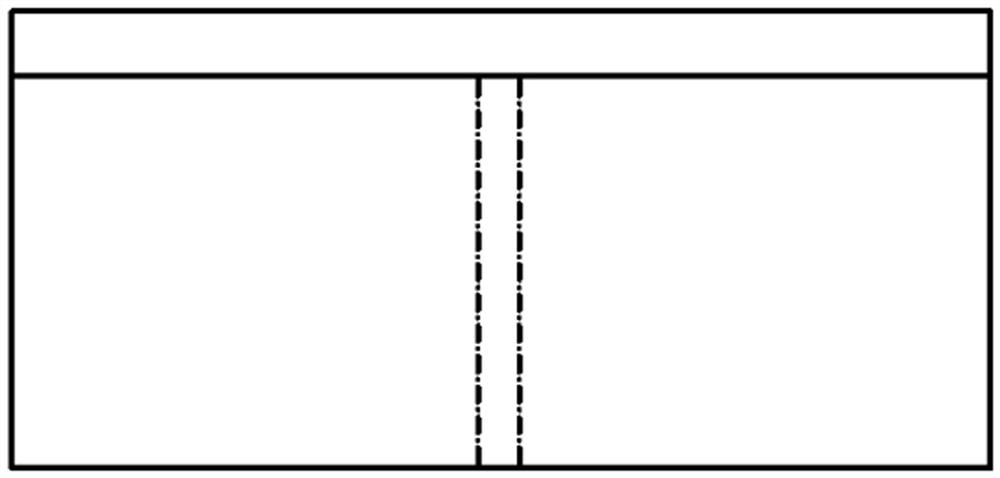

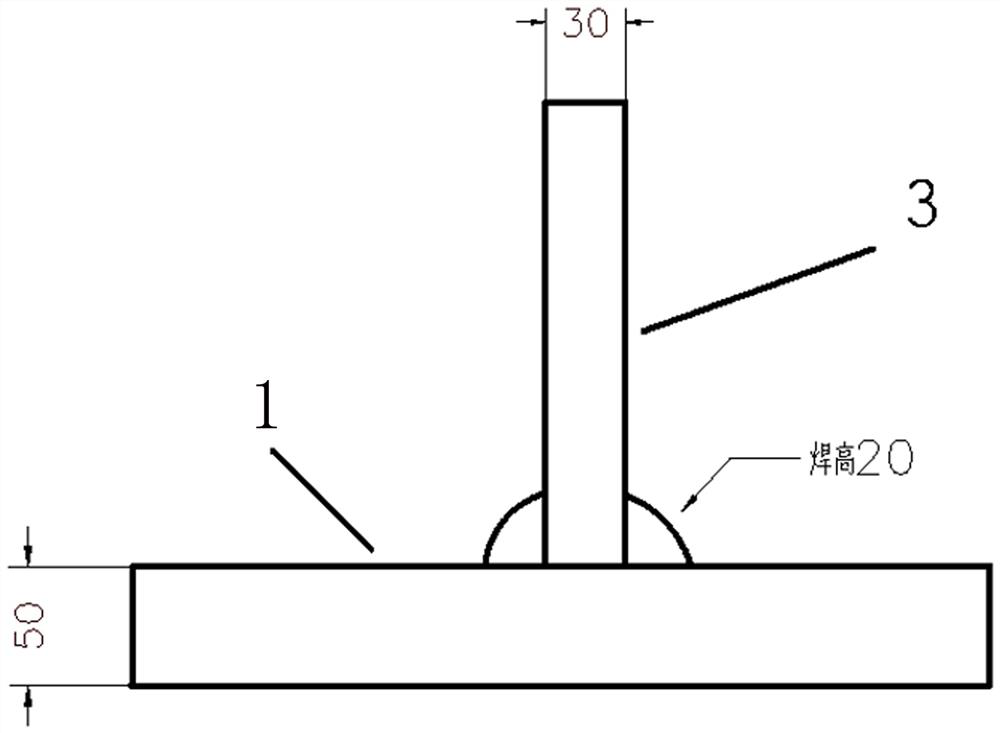

[0041] Provide flat plate 1, vertical plate 2 and vertical rib plate 3 with steel plate material of Q345. The thickness of flat plate 1, vertical plate 2 and vertical rib plate 3 are 50mm, 80mm and 30mm respectively, and the length of flat plate 1 is 1500mm and the width is 800mm. The K-shaped grooves of the flat plate 1 and the vertical plate 2 are designed to be 17mm in depth at the upper part and 33mm in the lower part. The vertical rib plate 3 is welded with the flat plate 1 and the vertical plate 2 by fillet welding, and the welding height is 20mm.

[0042] The flat plate 1 and the vertical rib plate 3 are connected by fillet welding. Since the flat plate 1 and the vertical rib plate 3 can be flipped freely, first turn the flat plate 1 over with the lower part facing up, adjust the level, and design the vertical rib plate 3 on the flat plate 1. The position is installed and positioned, and the gap is controlled at 0~1mm; then preheat the fillet weld and the range of 200mm...

Embodiment 2

[0051] Provide flat plate 1, vertical plate 2 and vertical rib plate 3 with steel plate material of Q235. The thickness of flat plate 1, vertical plate 2 and vertical rib plate 3 are 15mm, 20mm and 10mm respectively. The groove design is 10mm deep on the upper groove and 5mm on the lower part. The vertical rib plate 3 is welded with the flat plate 1 and the vertical plate 2 by fillet welding, and the welding height is 10mm.

[0052] First turn the plate 1 over, with the lower part facing up, adjust the level, install and position the vertical rib plate 3 at the designed position on the plate 1, and control the gap at 0~1mm; then preheat the fillet weld and its sides within 200mm. , start welding after the preheating temperature reaches the process requirements; first weld the fillet weld 5~10mm between the vertical rib plate 3 and the flat plate 1 side, and then weld 5~10mm on the other side; check the vertical rib plate 3 after welding If the vertical rib plate 3 is offset t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com