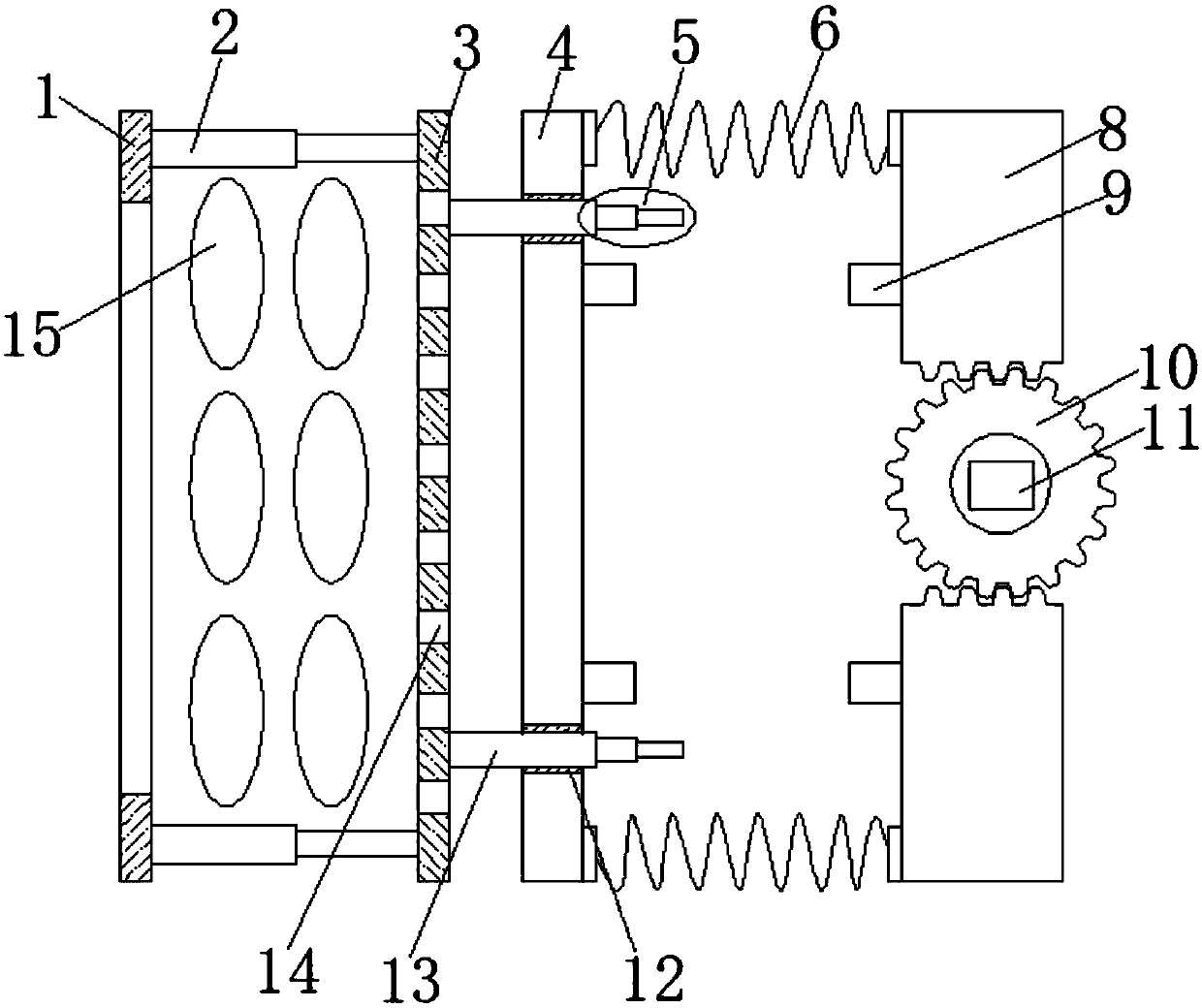

Pulse power amplifier overload protection device

A technology of overload protection and pulse power, applied in the direction of thermal switch components, etc., can solve the problems of metal sheet heating, insufficient metal sheet bending, affecting the service life of amplifiers, etc., to maintain normal use and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

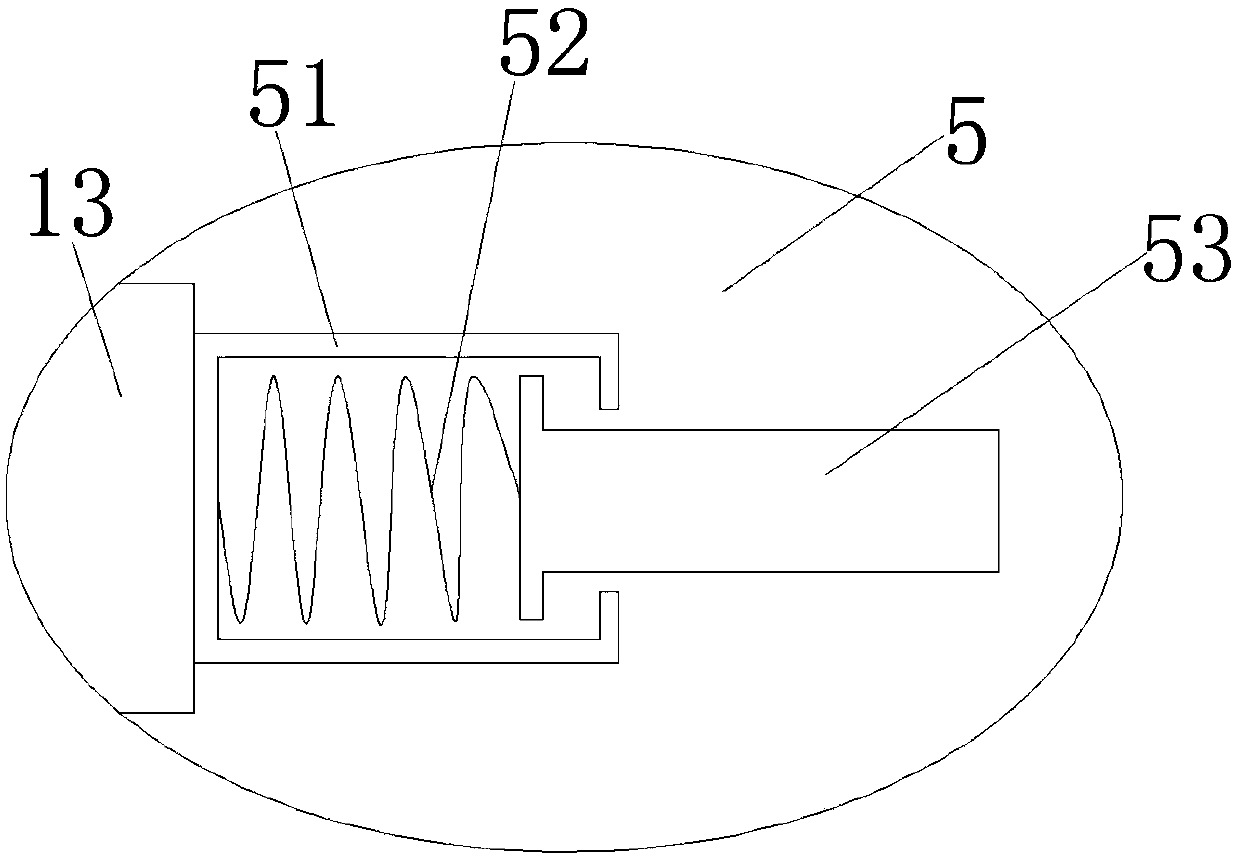

[0018] Example: When the internal current of the amplifier increases rapidly and the amplifier device is overheated, the heat generated by the device will rapidly increase the volume of the airbag 15 in the baffle 2 through the ventilation net, and then push the push plate 3 and drive the linkage rod 13 along the slide rail 12 moves to make the linkage rod 13 drive the shock absorber 5 to push the second contact plate 8 away from the first contact plate 4 quickly, and the contacts 9 are disconnected, which protects the circuit from overload and protects the amplifier. Function: After the temperature of the equipment drops to normal temperature, the temperature controller transmits the signal to the temperature sensor, and the temperature sensor receives the signal to make the reduction motor 11 drive the gear to rotate, and the gear 10 meshes to drive the second contact plate 8 to move closer to the first contact plate 4. Make the contacts 9 contact each other and energize, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com