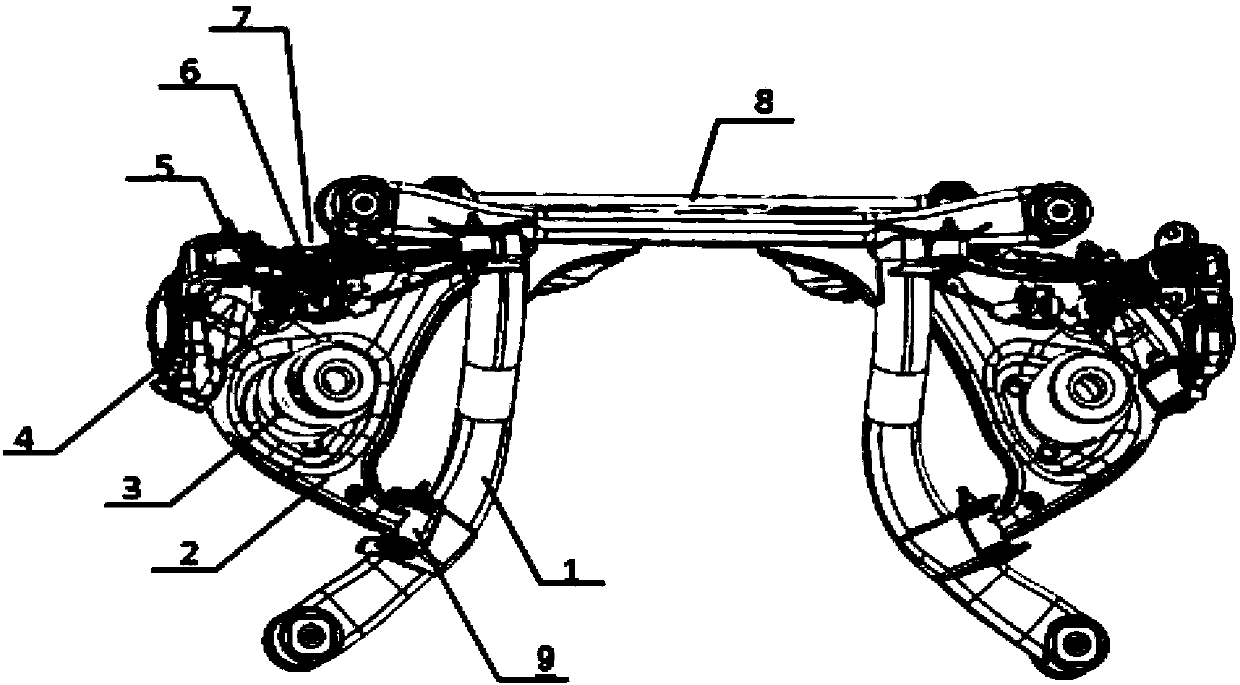

Swing arm bush and swing arm bush assembly

A technology of bushings and steel sleeves, which is applied to vehicle parts, transportation and packaging, and cantilevers mounted on pivots, etc., which can solve the impact of vehicle stability and NVH performance, and the control of stiffness in all directions must meet the requirements and affect the vehicle. Driving safety and other issues to achieve the effect of improving NVH and comfort, easy processing, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

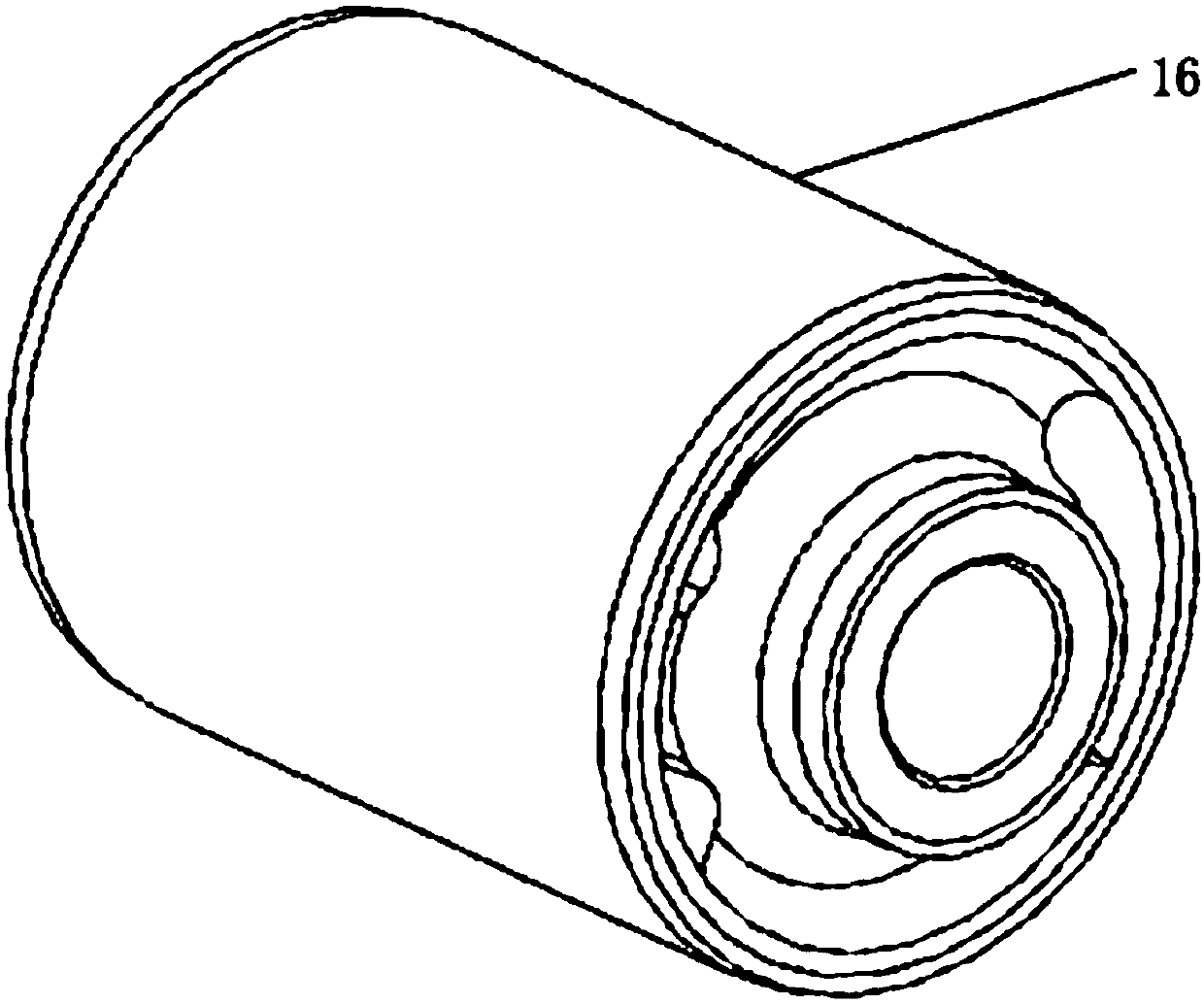

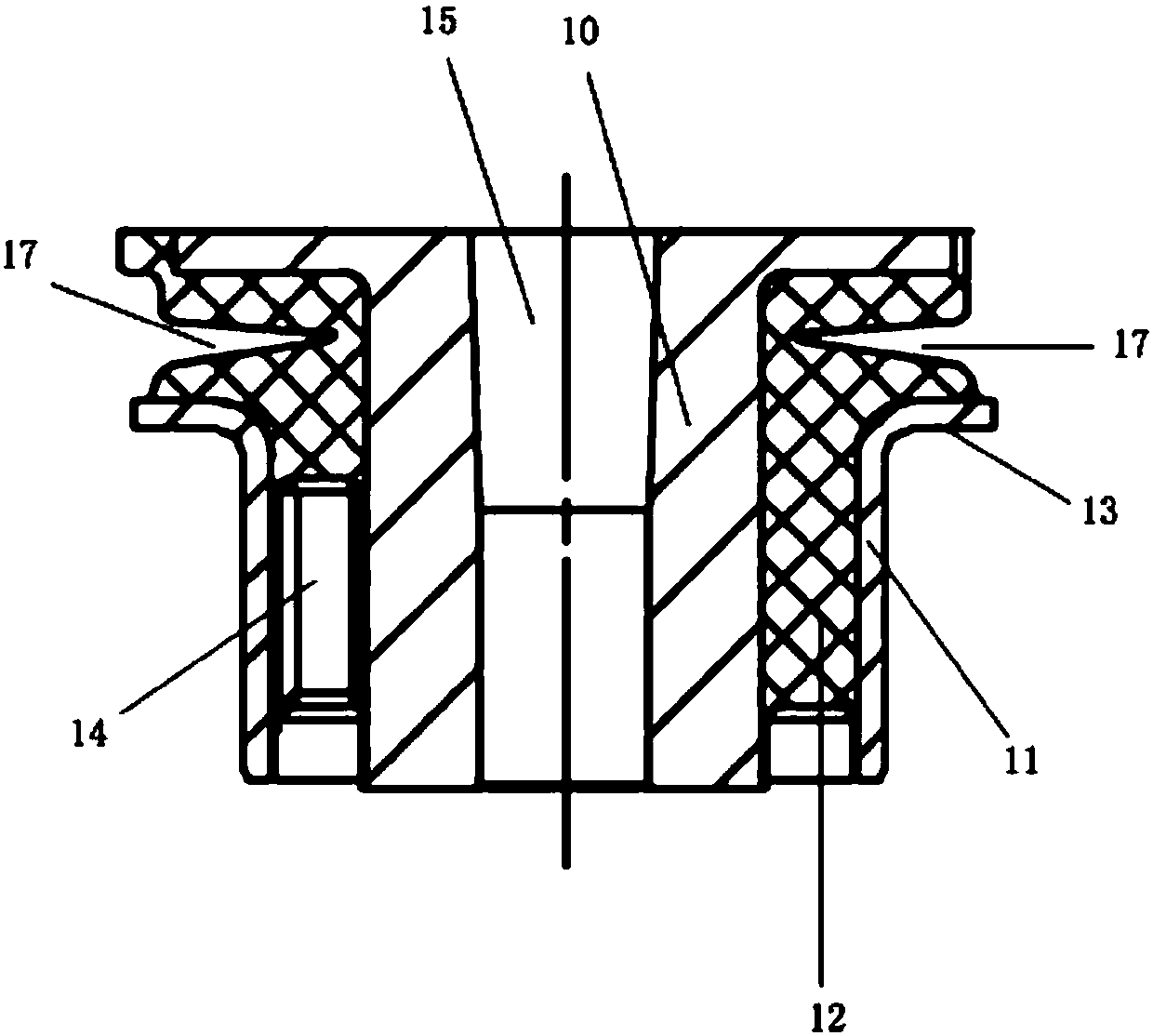

[0032] The following with attached Figure 3 to Figure 7 A swing arm bush and a swing arm bush assembly of the present invention are further described in detail.

[0033] A swing arm bushing of the present invention, please refer to Figure 3-7 , including an inner liner 10, a rubber main spring 12, an outer liner 11 and a mounting hole 15 which are sequentially socketed from inside to outside, the outer wall of the inner liner 10 is against the inner wall of the rubber main spring 12, and the rubber main The outer wall of the spring 12 is in contact with the inner wall of the outer lining pipe 11, and the upper end of the outer lining pipe 11 is provided with a horizontal flange 13 extending horizontally outward, and the inner wall of the upper surface of the flange 13 is in contact with the rubber main spring 12. The outer wall of the bending part is against each other, and the installation hole 15 penetrates through the central position of the inner liner pipe 10 from top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com