Gas circulation flow-guiding system used for heat treatment furnace

A heat treatment furnace and gas circulation technology, which is applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as poor furnace temperature uniformity and poor air flow consistency, and achieve improved furnace temperature uniformity, simple installation, and convenient structure expansion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

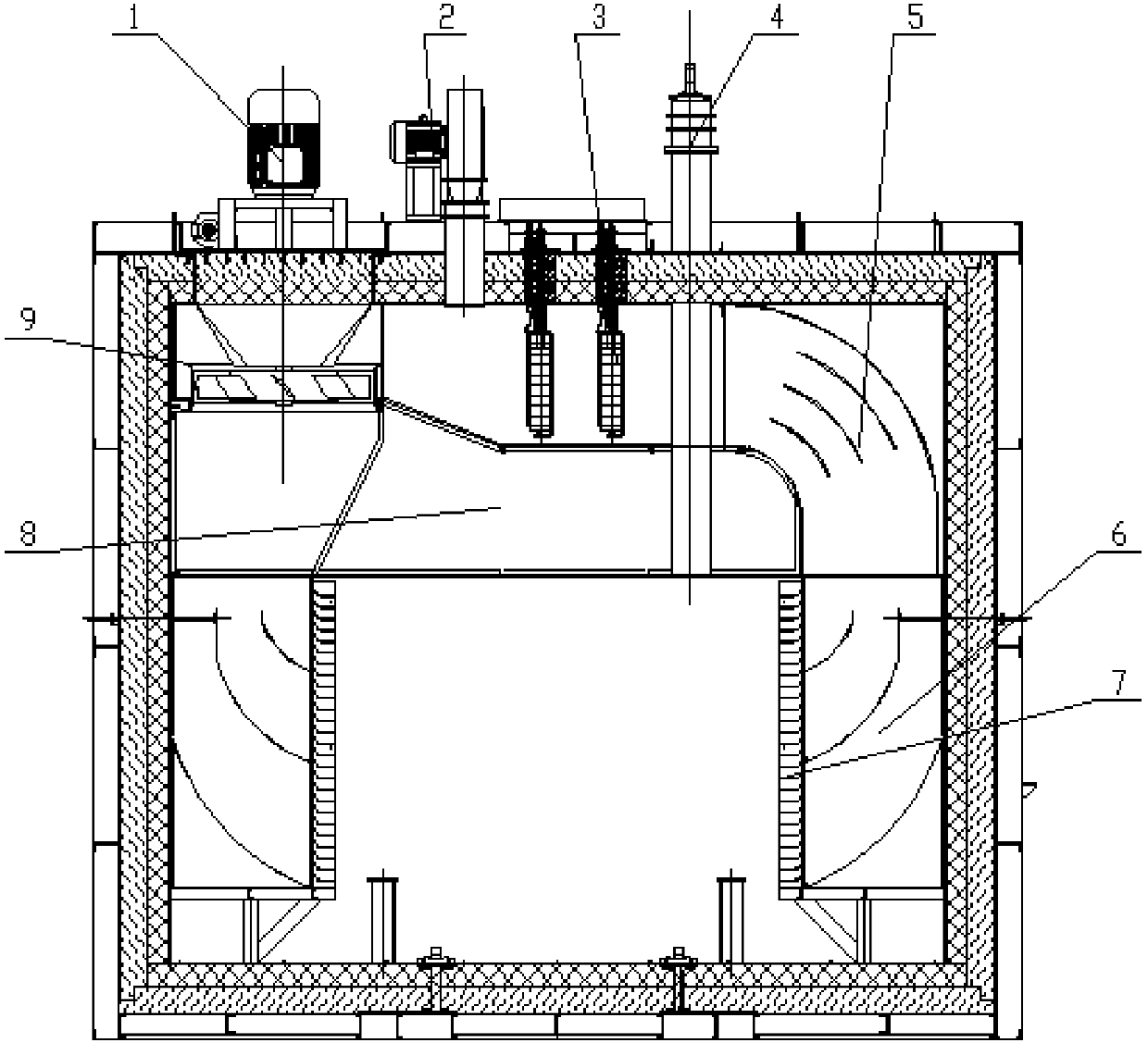

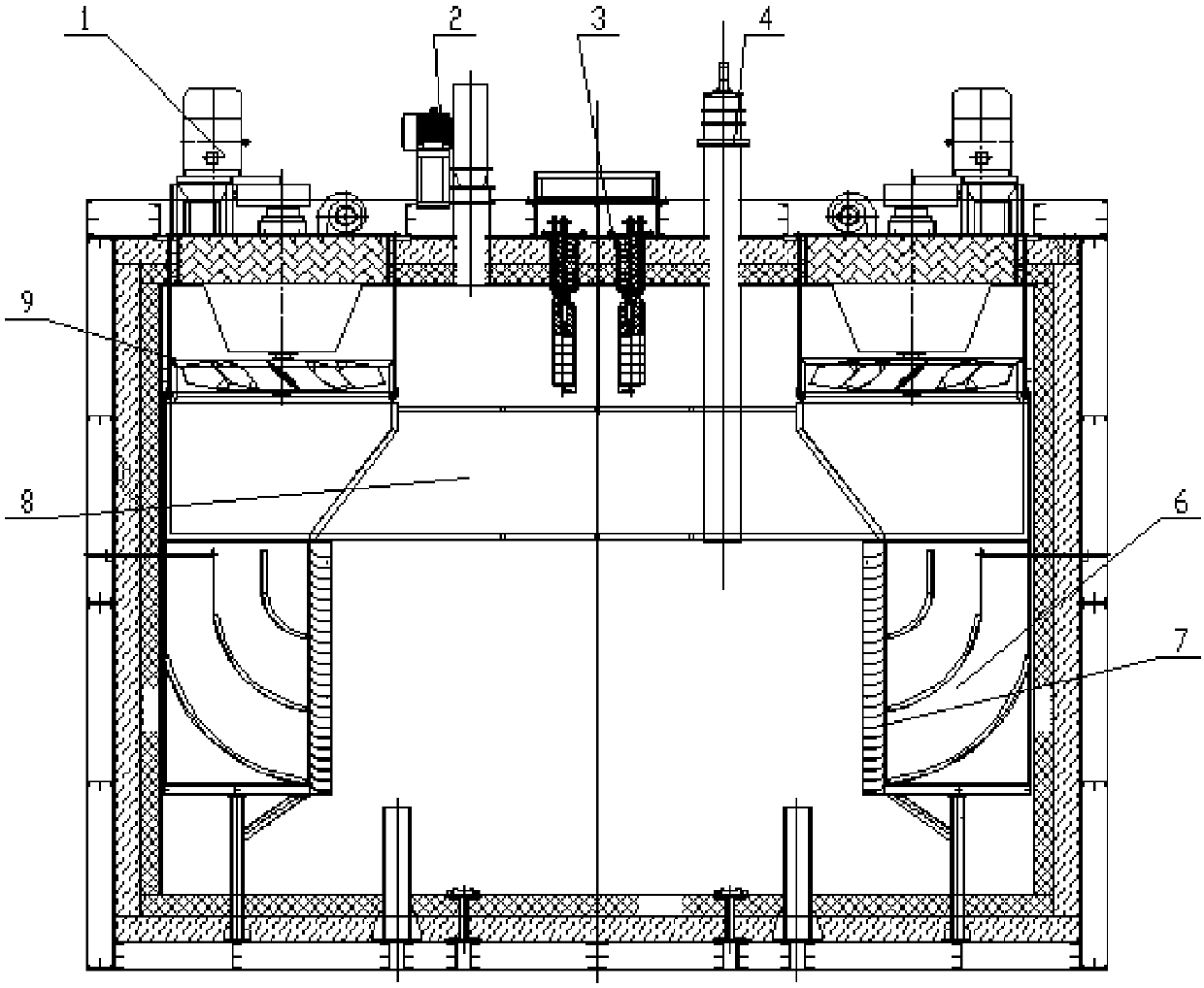

[0037] Below in conjunction with accompanying drawing the present invention is described in further detail, please refer to Figures 1 to 2 .

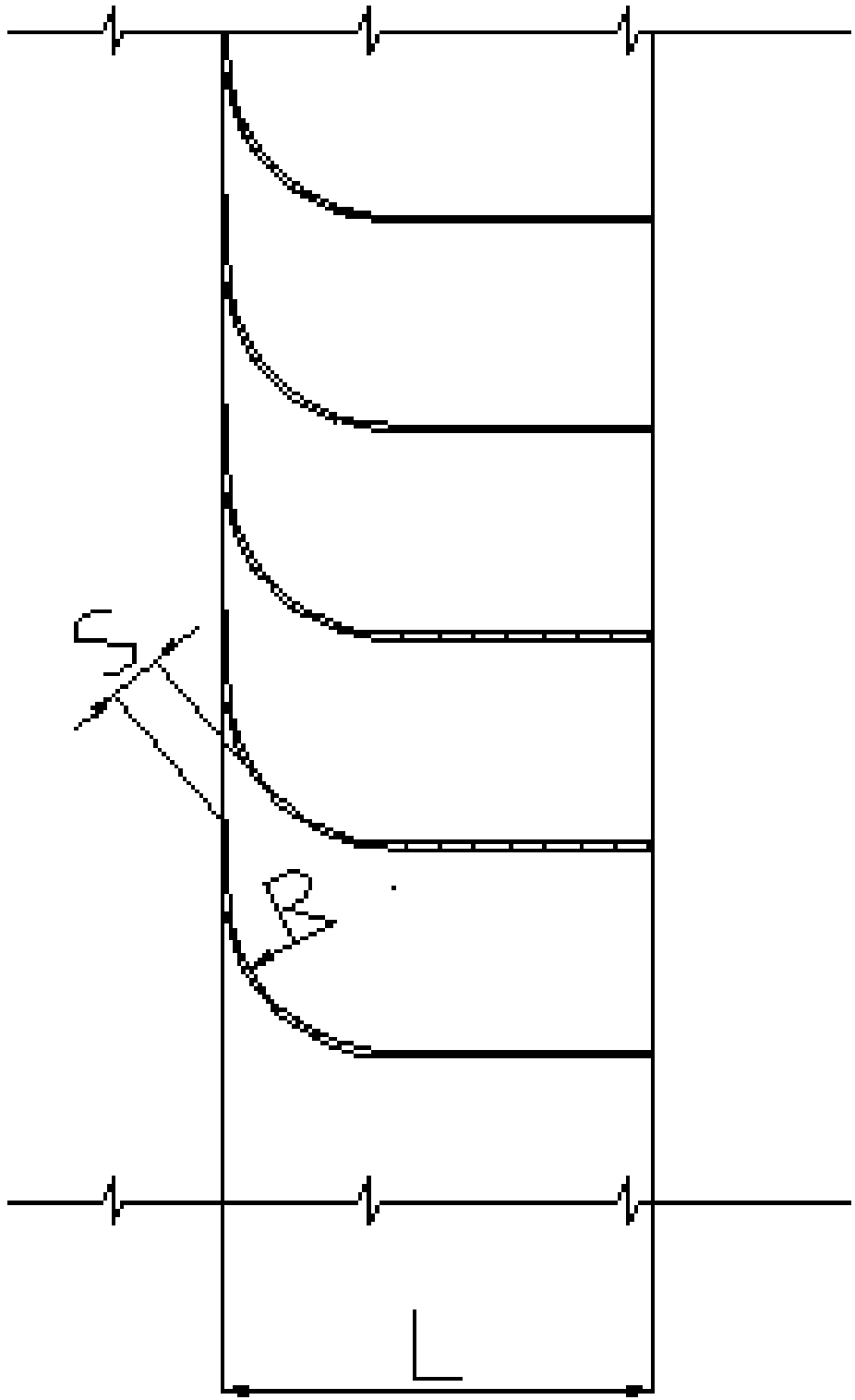

[0038] The present invention relates to an embodiment, including a circulating fan, a cold air device, a heating device, an exhaust device, a 90° steering deflector, an equalizing air box, an arc-shaped louver frame, an air duct separation frame and an air guide tube;

[0039] The circulation fan is installed on the heat treatment furnace, and the gas outside the furnace is introduced into the furnace;

[0040] The 90° diversion deflector, the air channel partition frame and the pressure equalizing air box are arranged in the furnace cavity of the heat treatment furnace to jointly form an annular air channel;

[0041] The air guide tube communicates with the annular air channel, and guides the gas sent by the circulating fan into the annular air channel;

[0042] The 90° turning guide device is used as a part of the annular air chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com