Dual web H-shaped aluminum alloy frame structure allowing pipelines to pass

A frame structure and double-web technology, applied in the field of building structure research, can solve the problems of self-heavy, easy to be corroded, increase construction cost, etc., and achieve the effect of reducing self-weight, easy processing and forming, and saving the cost of manual maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

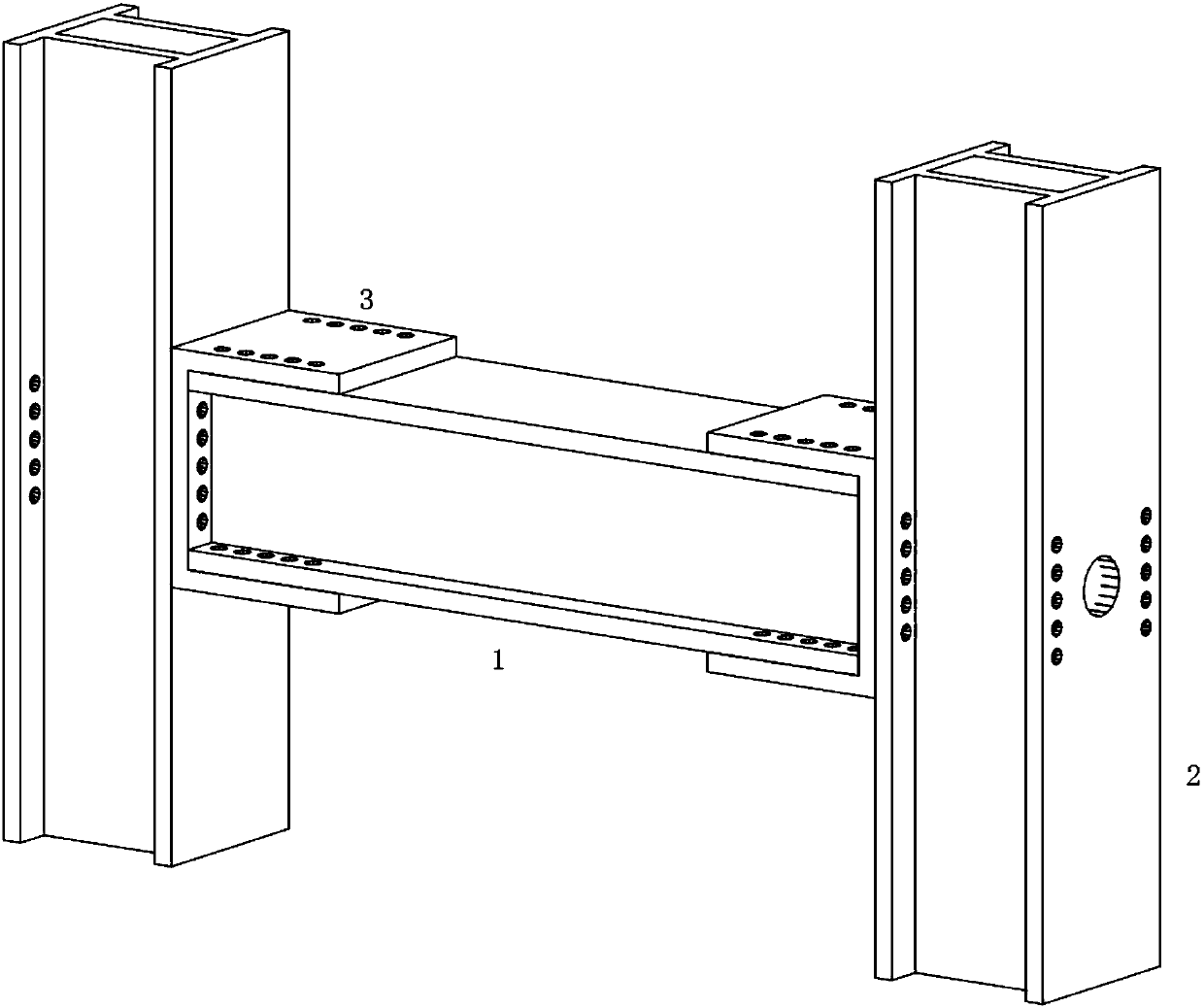

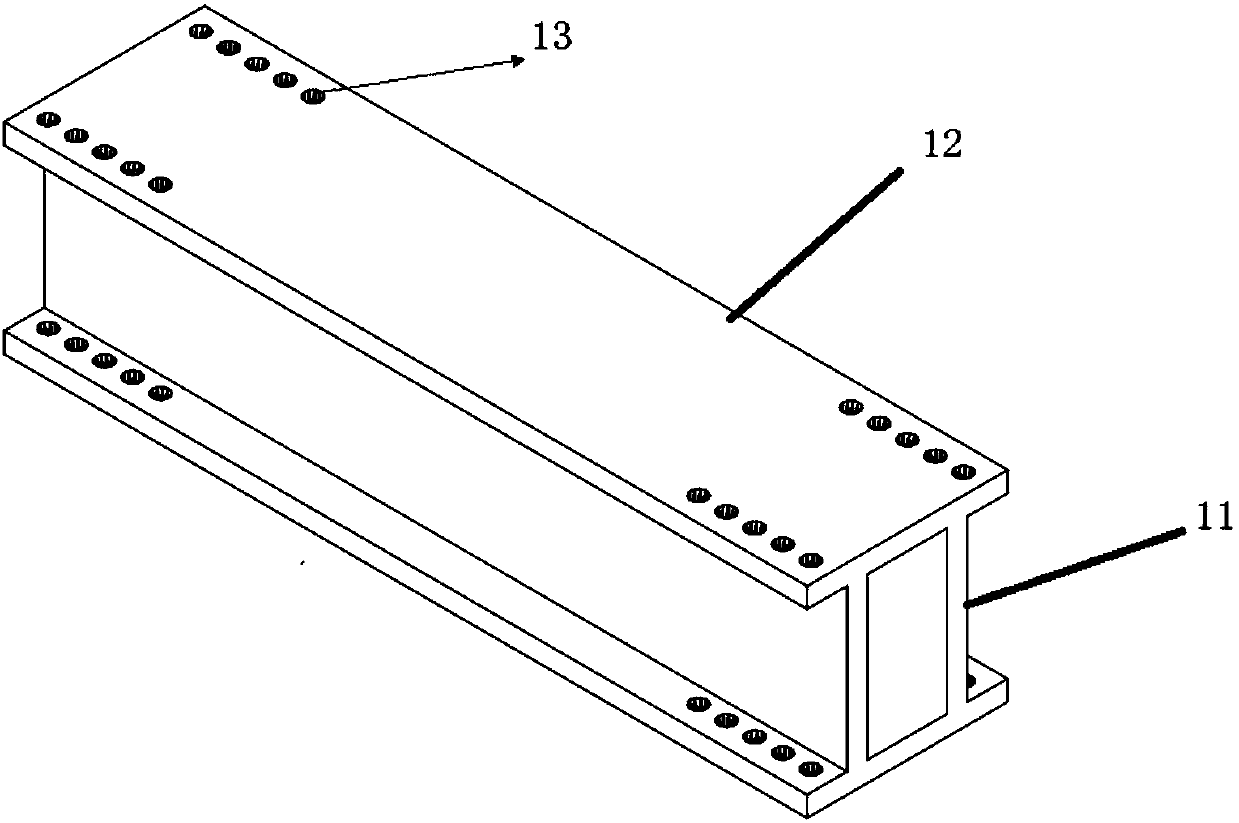

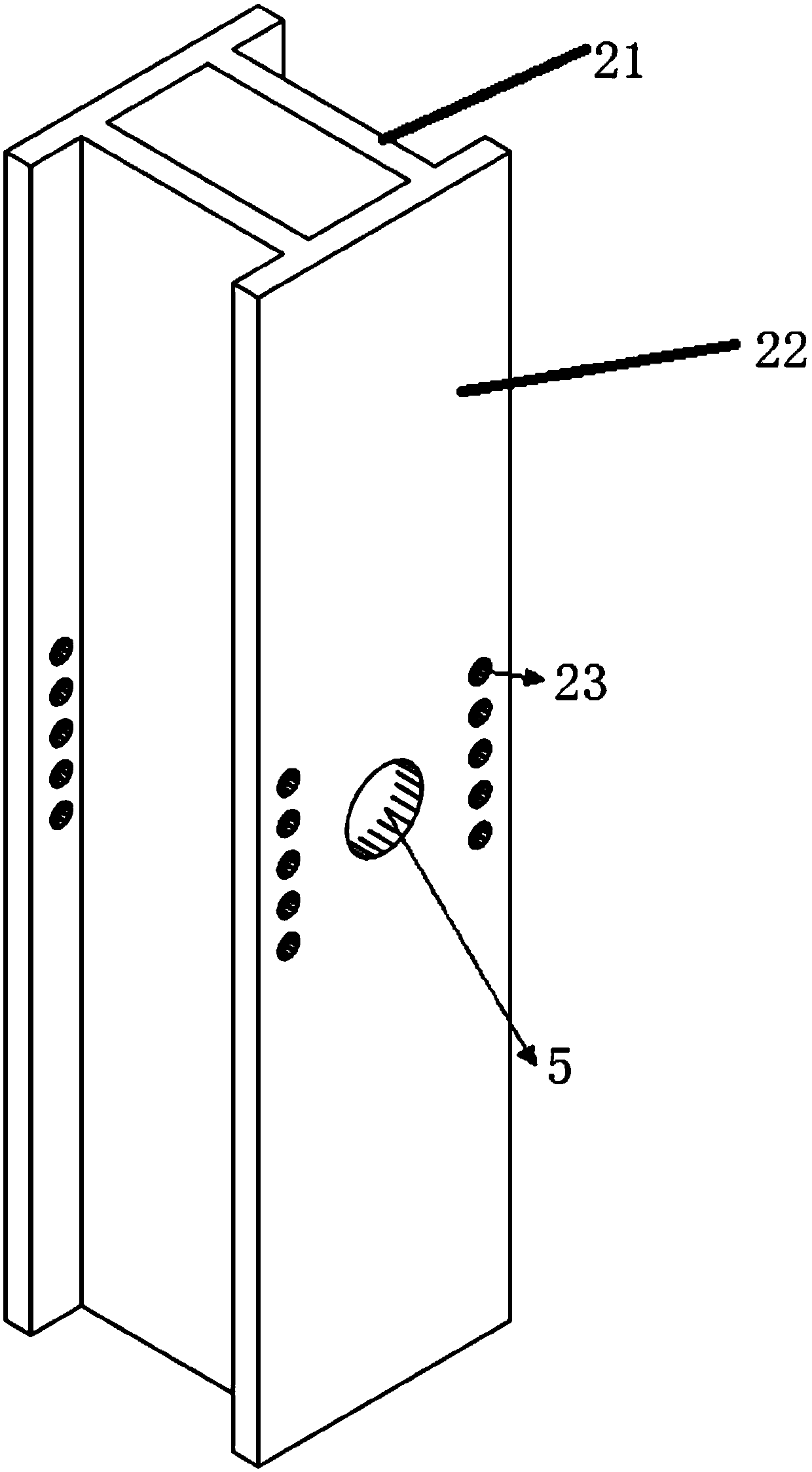

[0030] see Figure 1~5 , the present invention relates to a novel double-web H-shaped aluminum alloy frame structure that can penetrate pipelines, mainly consisting of four parts: a double-web H-shaped aluminum alloy beam member (1), a double-web H-shaped aluminum alloy column The component (2), the C-type connected aluminum alloy plate component (3) and the connector are composed. Firstly, the required beam-column section size is calculated according to the load combination, and the shear bearing capacity of the connectors on the C-shaped aluminum alloy plate member (3) is checked to determine the number and arrangement of the connectors. During the factory prefabrication process of each component, on both sides of the flange of the double-web H-shaped aluminum alloy beam member (1), on both sides of the flange of the double-web H-shaped aluminum Holes are opened at the corresponding positions of the alloy plate member (3), and holes of the size required for the connectors a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com