Hydrodynamic plain bearing and exhaust-gas-driven turbocharger

A sliding bearing, hydrodynamic technology, applied in sliding contact bearings, bearings in rotary motion, bearings, etc., to achieve the effect of reducing oil pressure demand, improving bearing capacity, and low noise emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

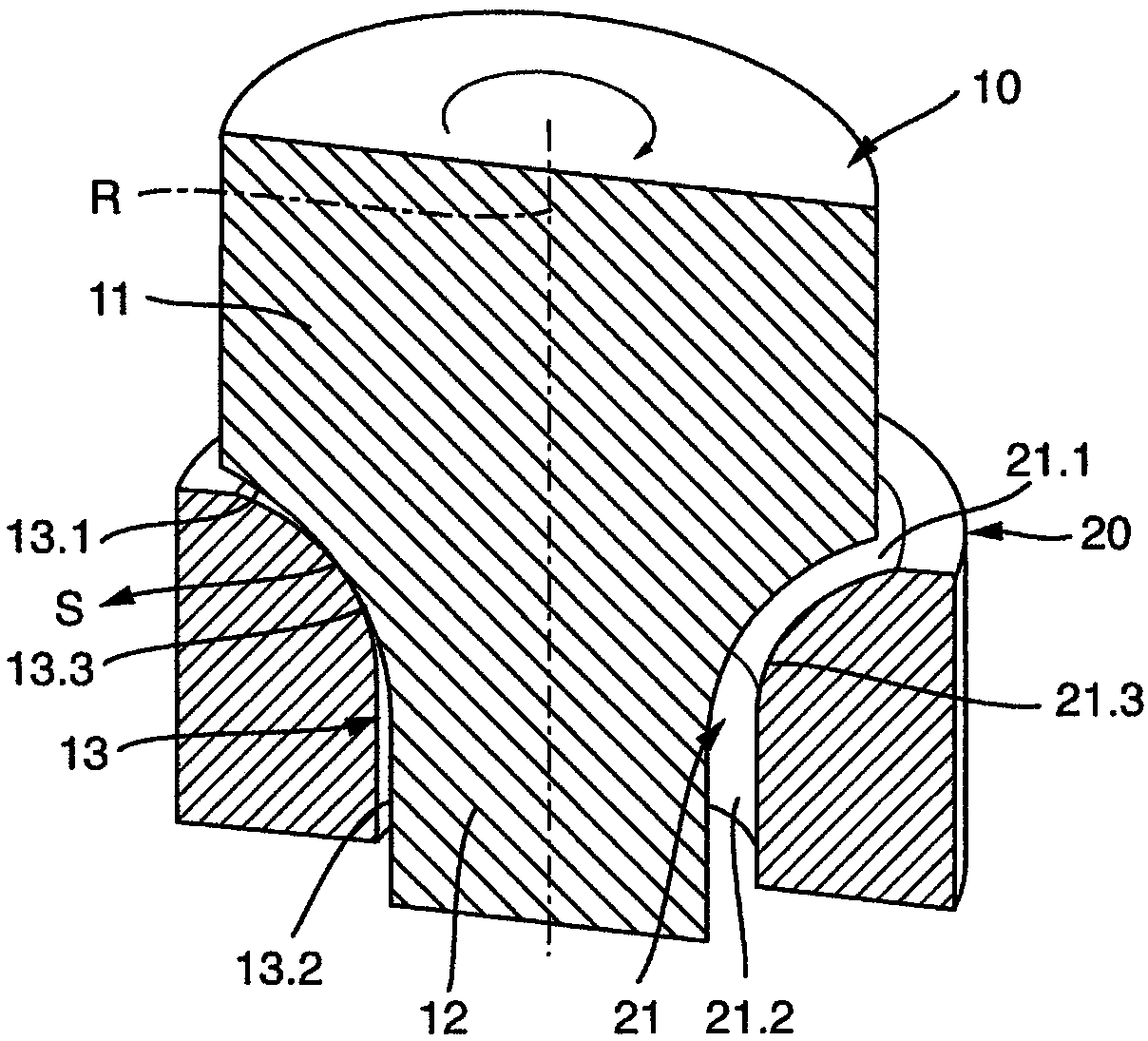

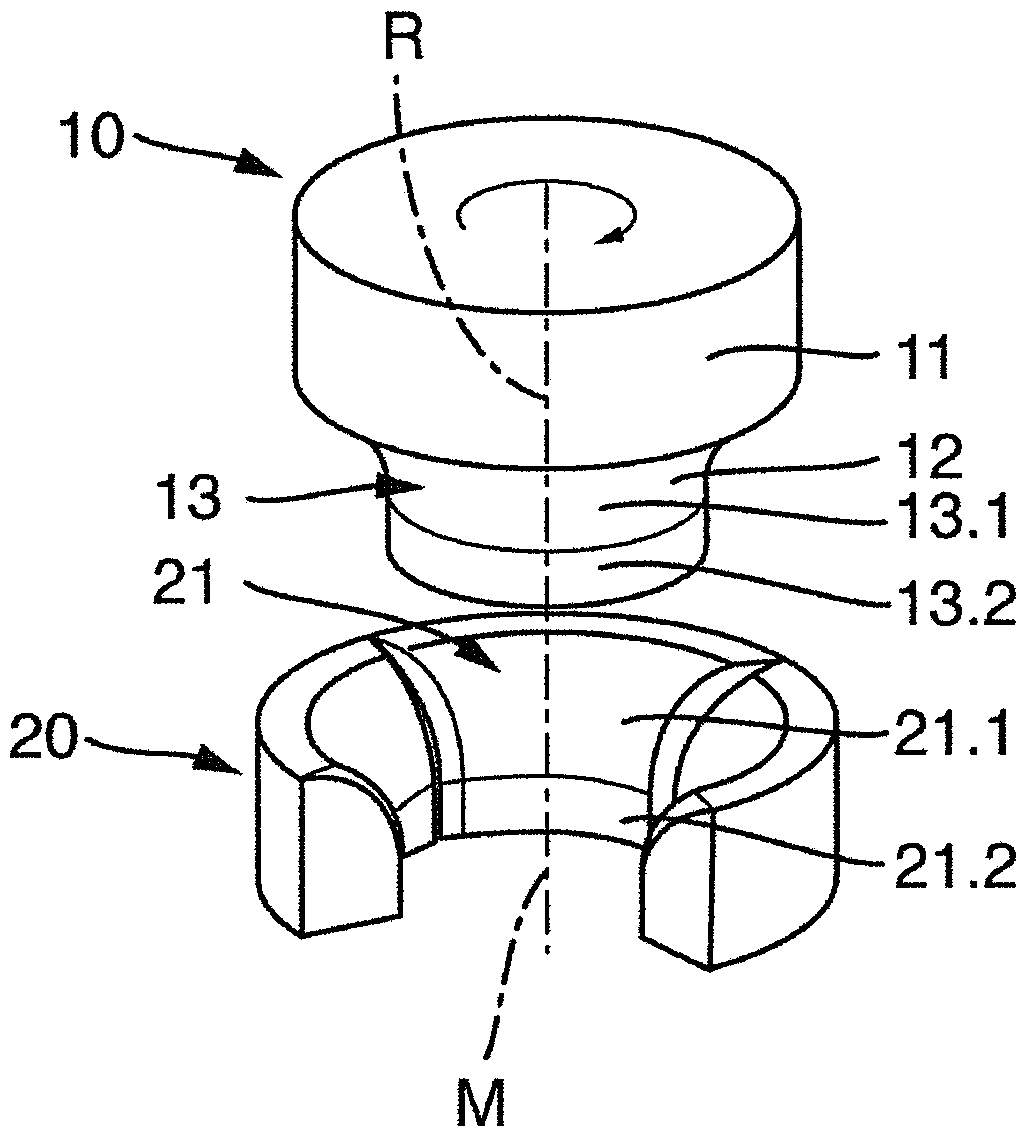

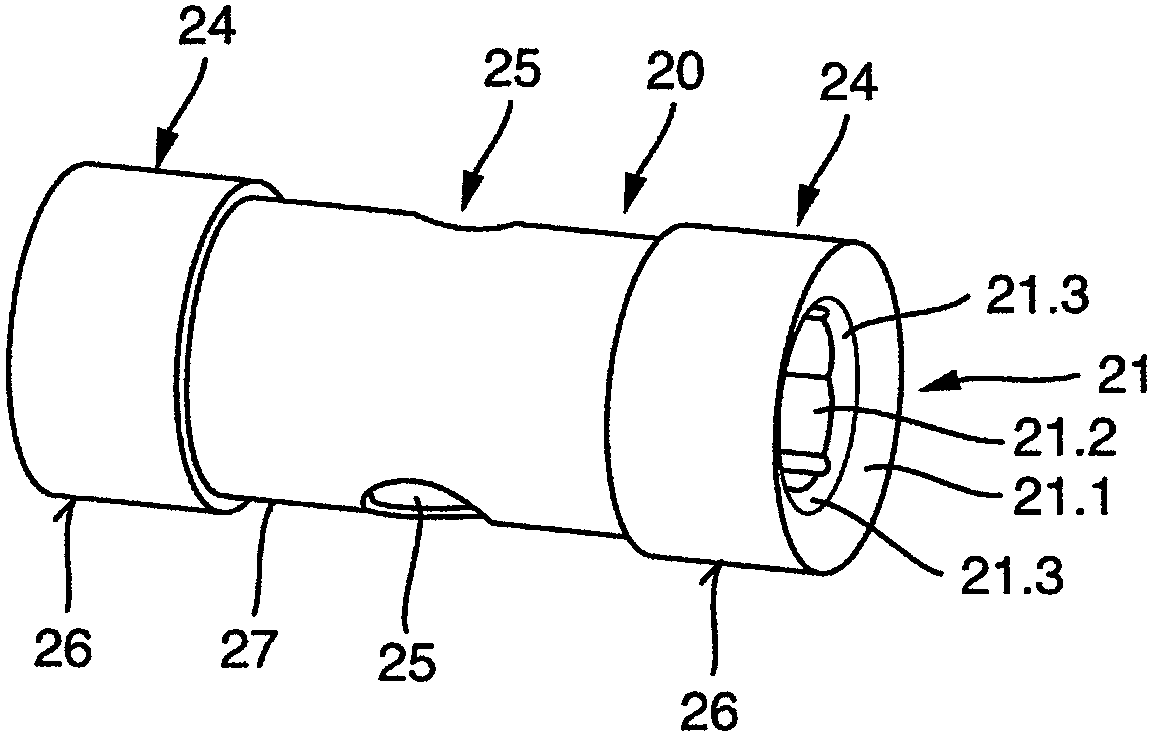

[0037] figure 1 and figure 2 A hydrodynamic plain bearing with a rotor 10 and a stator 20 is shown. For this purpose, a schematic sectional view along the rotor axis R of the rotor 10 is selected. The rotor 10 has a coupling piece 11 to which a bearing segment 12 is connected. A mechanical component such as a gear or the like can be indirectly or directly connected to the coupling piece 11 . The bearing segment 12 has a particularly rotationally symmetrical rotor bearing surface 13 . For this purpose, the rotor bearing surface 13 forms a continuous bearing contour in the direction of the rotational axis of the plain bearing. The support contour is formed by two contour sections 13.1, 13.2 and a transition section 13.3. In the invention, therefore, the distance of the bearing contour from the axis of rotation can vary along the axis of rotation (longitudinal center axis).

[0038] According to the invention and in particular according to figure 1 As shown in the variant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com