Mutually-inserted and nested type vessel fast-open door

A nested, container technology, applied in the direction of pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of large axial space, inconvenient operation, weakened flange pressure bearing capacity, etc., to achieve pressure bearing Good performance, axial space saving and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

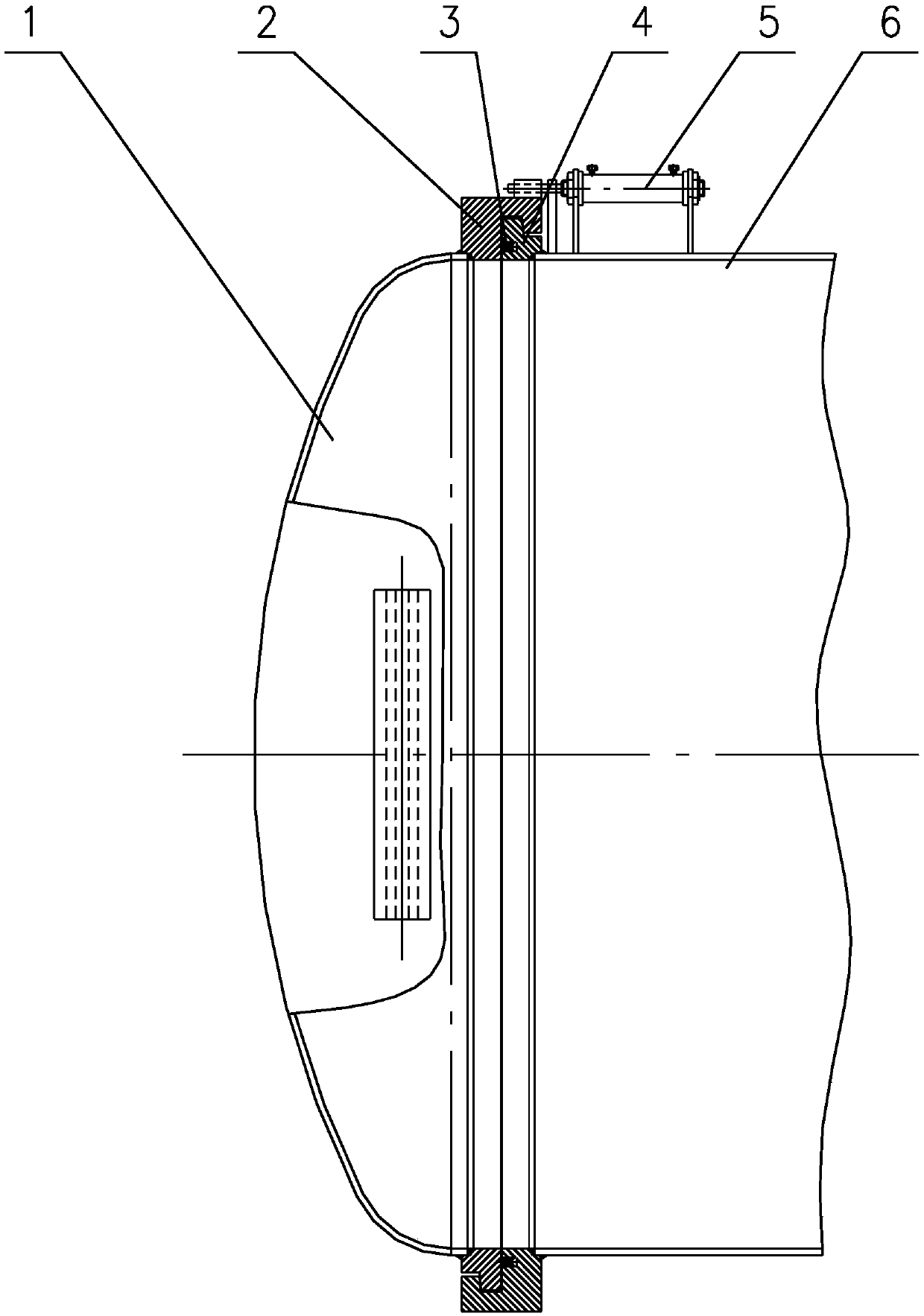

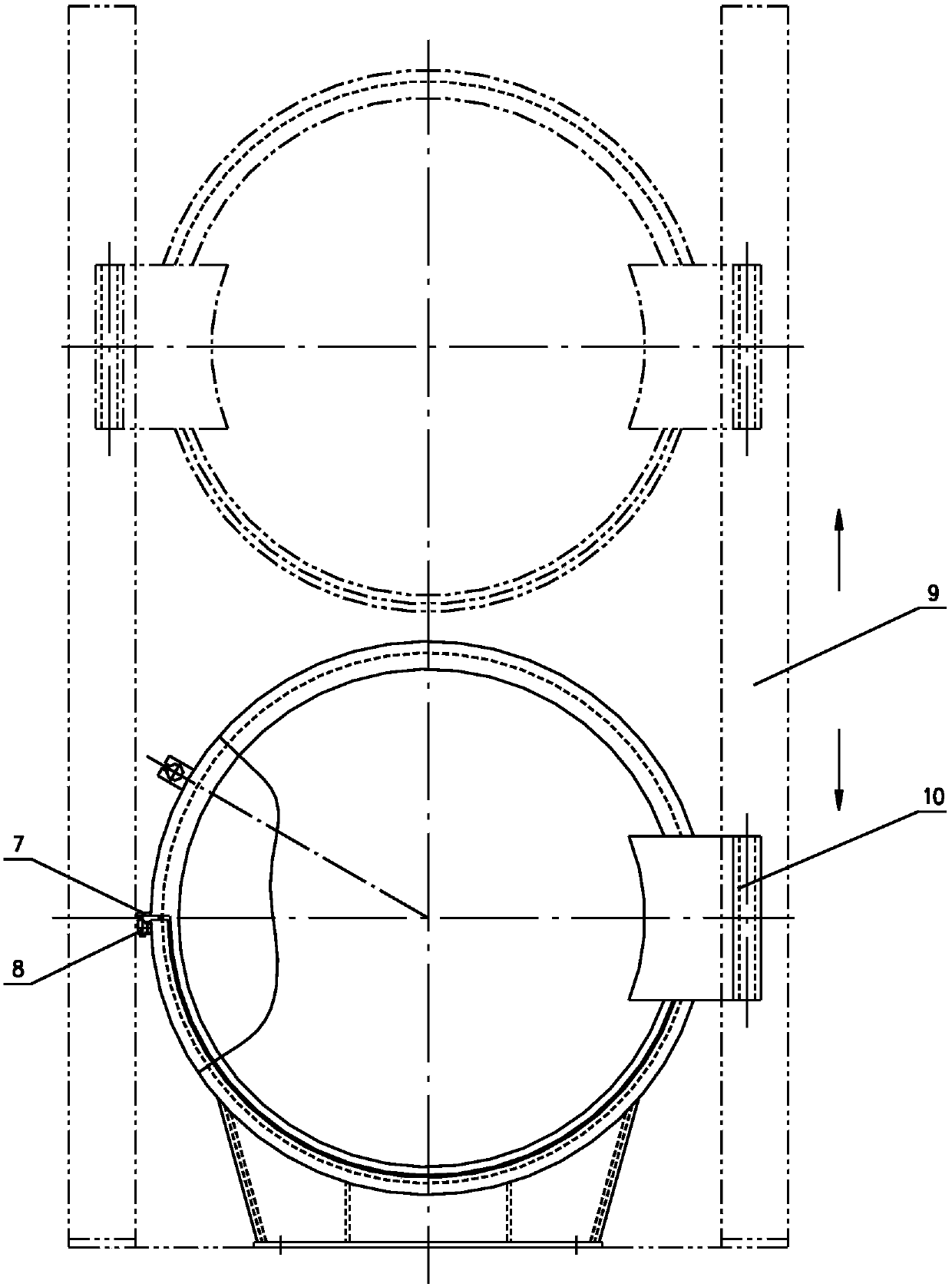

[0032] Embodiment 1, when the quick-opening door needs to be closed, the head flange 2 and the container head 1 are translated along the guide rail 9 perpendicular to the axis of the container cylinder 6 through the guide block 10, so that the head of the head flange 2 The flange shoulder 2-1 part is inserted into the cylinder flange clamp ring 4-2 of the cylinder flange 4, and the head flange clamp ring 2-2 part of the head flange 2 hooks the cylinder When the stopper 7 of the head flange 2 hits the stroke control switch 8 on the part of the flange shoulder 4-1 of the flange 4, the head flange 2 stops moving, and the cylinder flange 4 and the head method The flange 2 forms a complete nesting structure. At this time, it can be started and put into the safety interlock device 5, and then the intake (steam) pressure is increased, and the container production system is running. If the stopper 7 on the head flange 2 does not touch If the upstroke control switch 8, the cylinder fla...

Embodiment 2

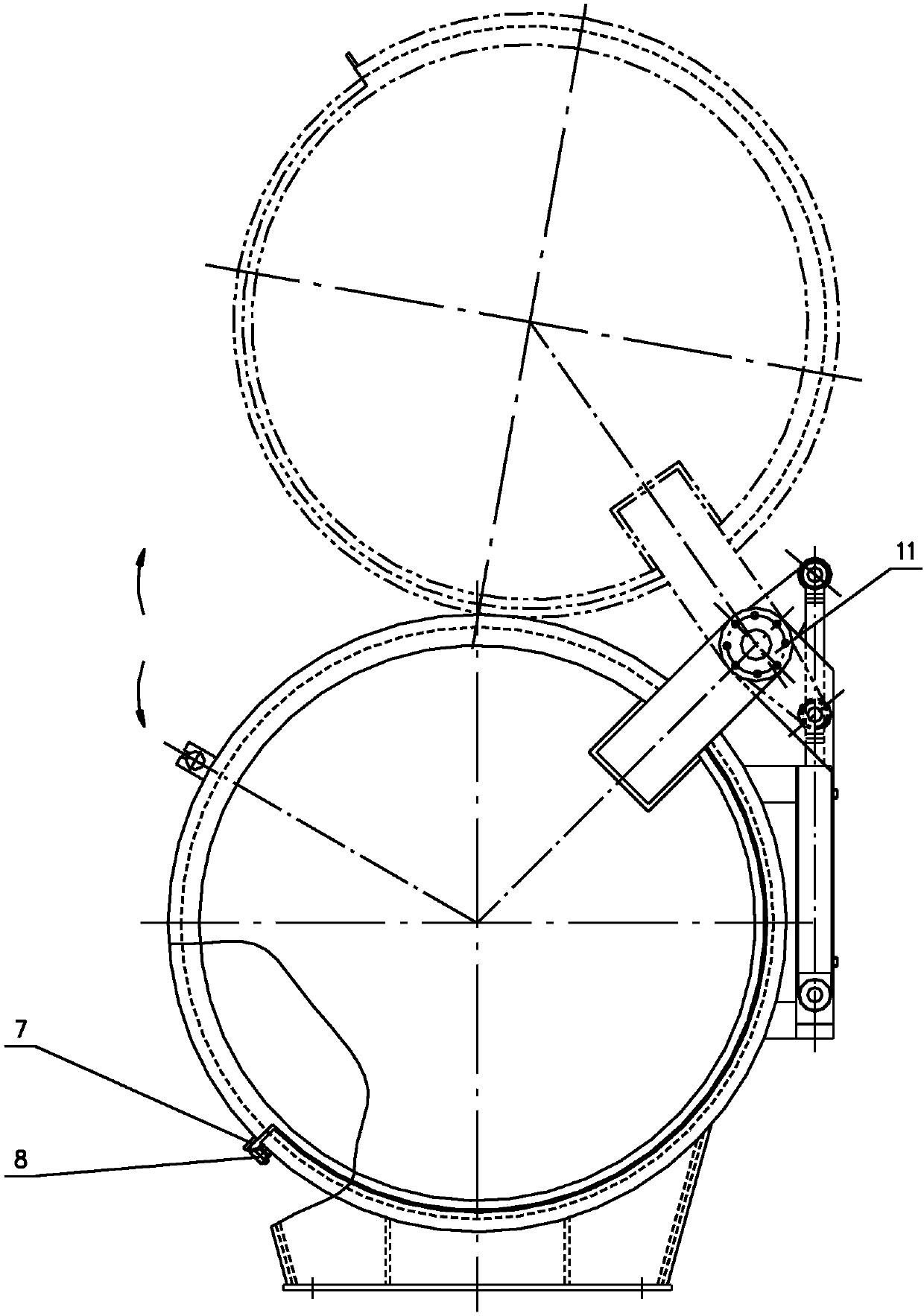

[0034] Embodiment 2, the difference from Embodiment 1 is that the radial translation of the opening and closing cover is changed to horizontal rotation around the rotation axis, and the container head 1 is rotated through the translational opening device 11 to realize the head flange 2 and the cylinder flange. 4's are fully nested or separated.

[0035] For the whole product, the opening and closing cover only needs radial translation or horizontal rotation, no other steps are required, the operation is extremely convenient, and it is easy to set up intelligently, and the axial space is saved because there is no need for axial movement or outward rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com