Rotary plate positioning device, loading transmission system and plasma processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

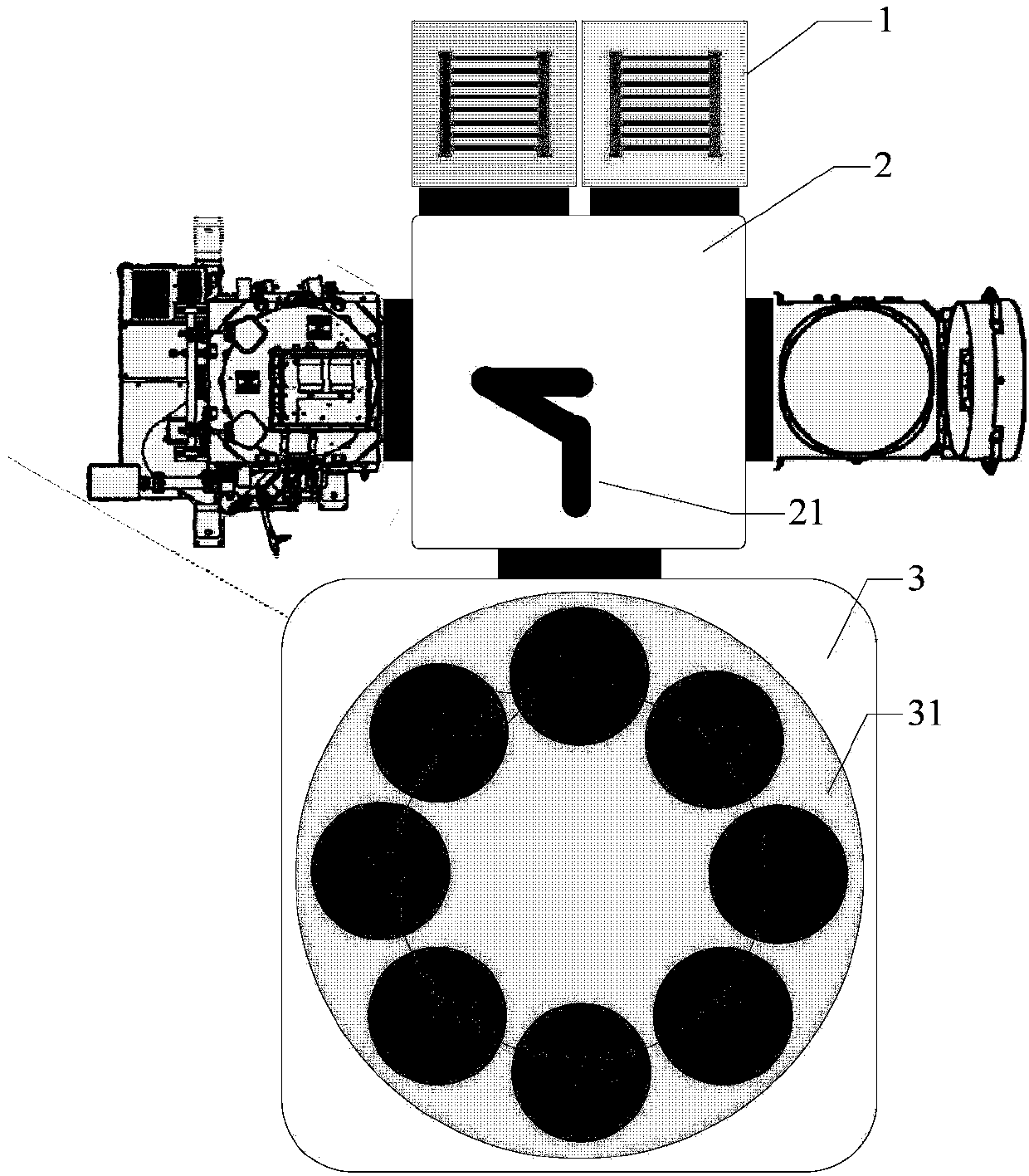

Image

Examples

Embodiment 1

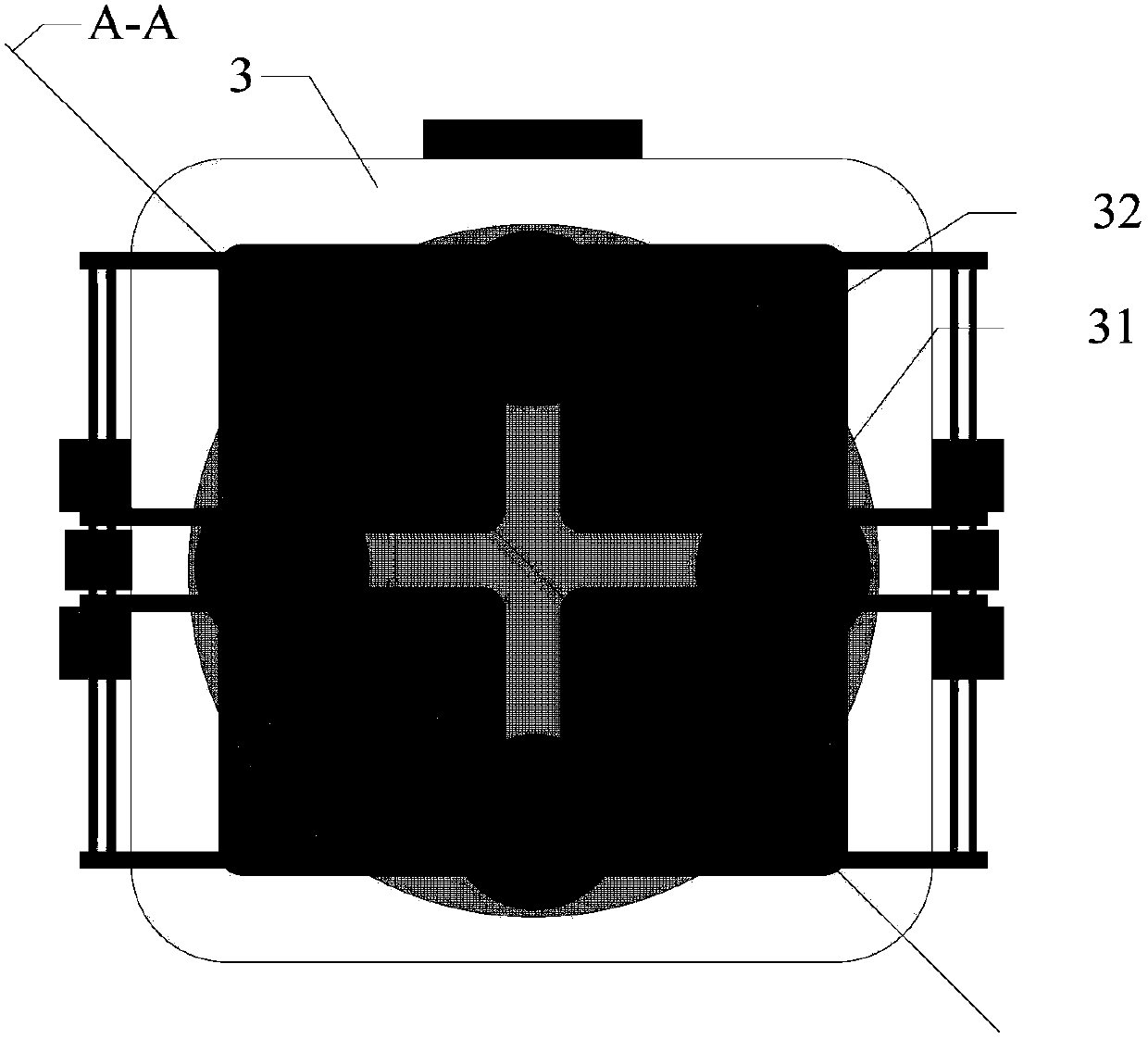

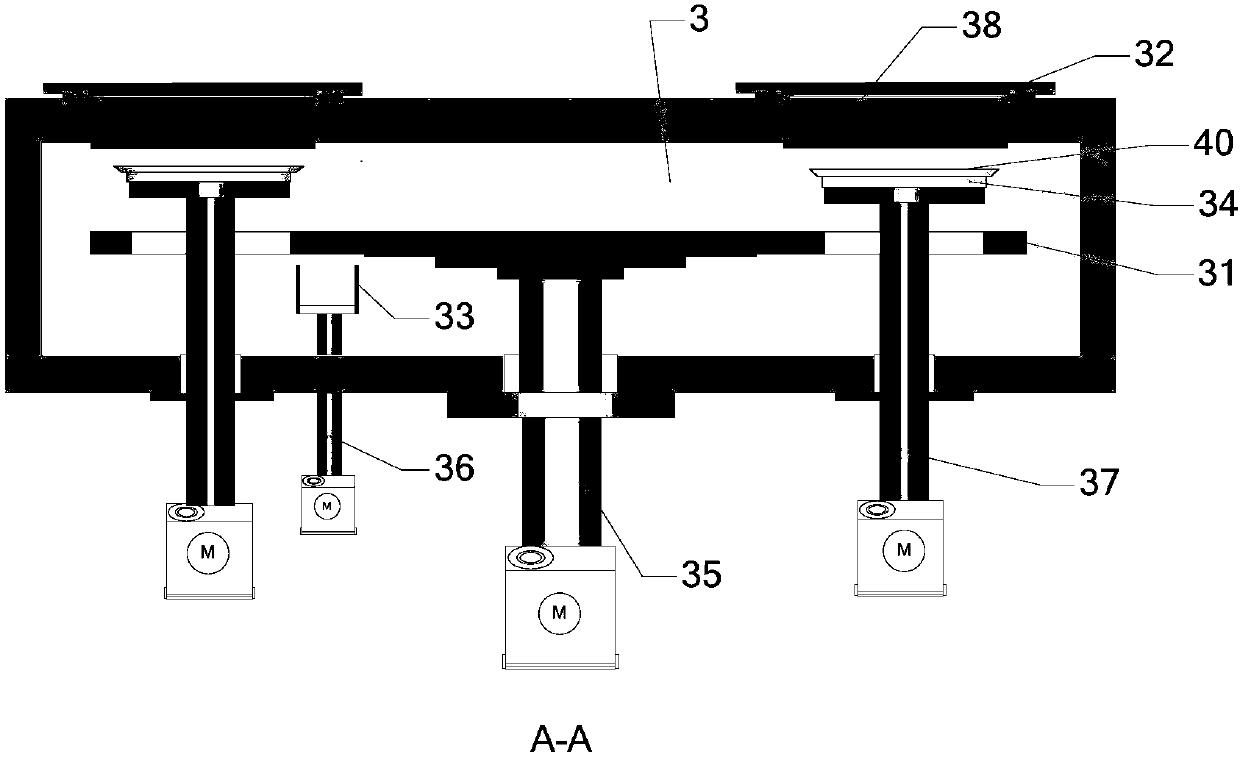

[0045] Figure 4A It is a top view of a turntable positioning device provided in Embodiment 1 of the present invention. Figure 4B for Figure 4A Side view on A upward. Please also refer to Figure 4A with Figure 4B , in this embodiment, the turntable 50 is provided with stations 51 , the number of stations 51 is multiple, and arranged at intervals along the circumference of the turntable 50 .

[0046] In the position detection unit, the first identification module includes a first protrusion 54, the first protrusion 54 is arranged on the outer peripheral wall of the turntable 50, and the number and position correspond to the number and position of the station 51 one by one; the first detection The module includes a first distance sensor 52 and a first controller (not shown in the figure), wherein the first distance sensor 52 is arranged on the periphery of the outer peripheral wall of the turntable 50, for when the turntable 50 rotates from its origin position, the A pa...

Embodiment 2

[0058] Figure 6A It is a top view of the turntable positioning device provided by Embodiment 2 of the present invention. Figure 6B for Figure 6A Sectional view along line A-A in middle. Please also refer to Figure 6A with Figure 6B , in this embodiment, the turntable 50 is provided with stations 51 , the number of stations 51 is multiple, and arranged at intervals along the circumference of the turntable 50 .

[0059] In the in-position detection unit, the first identification module includes a first through hole 61 that is arranged on the bearing surface where the station 51 of the turntable 50 is located (that is, the surface of the turntable for carrying workpieces) and penetrates through the thickness of the turntable 50, and The quantity and the position of the first through hole 61 correspond to the quantity and the position of the station 51 one by one; The radiation sensor 63 includes a transmitting end and a receiving end respectively arranged on the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com