Double-faced automatic feeding device

An automatic feeding technology, which is applied in animal feeding devices, animal drinking devices, applications, etc., can solve the problems of feed waste, easy access to troughs, trampling and waste of feed, etc., and achieves improved feeding quality, simple structure, and simplified structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

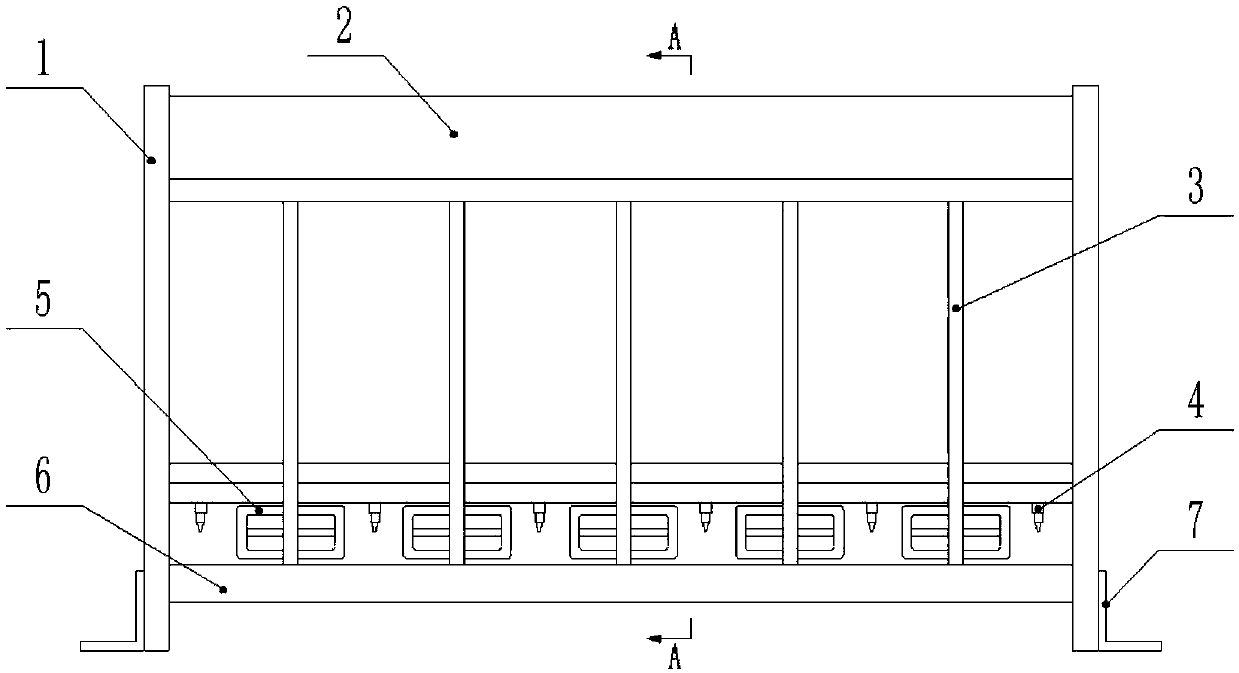

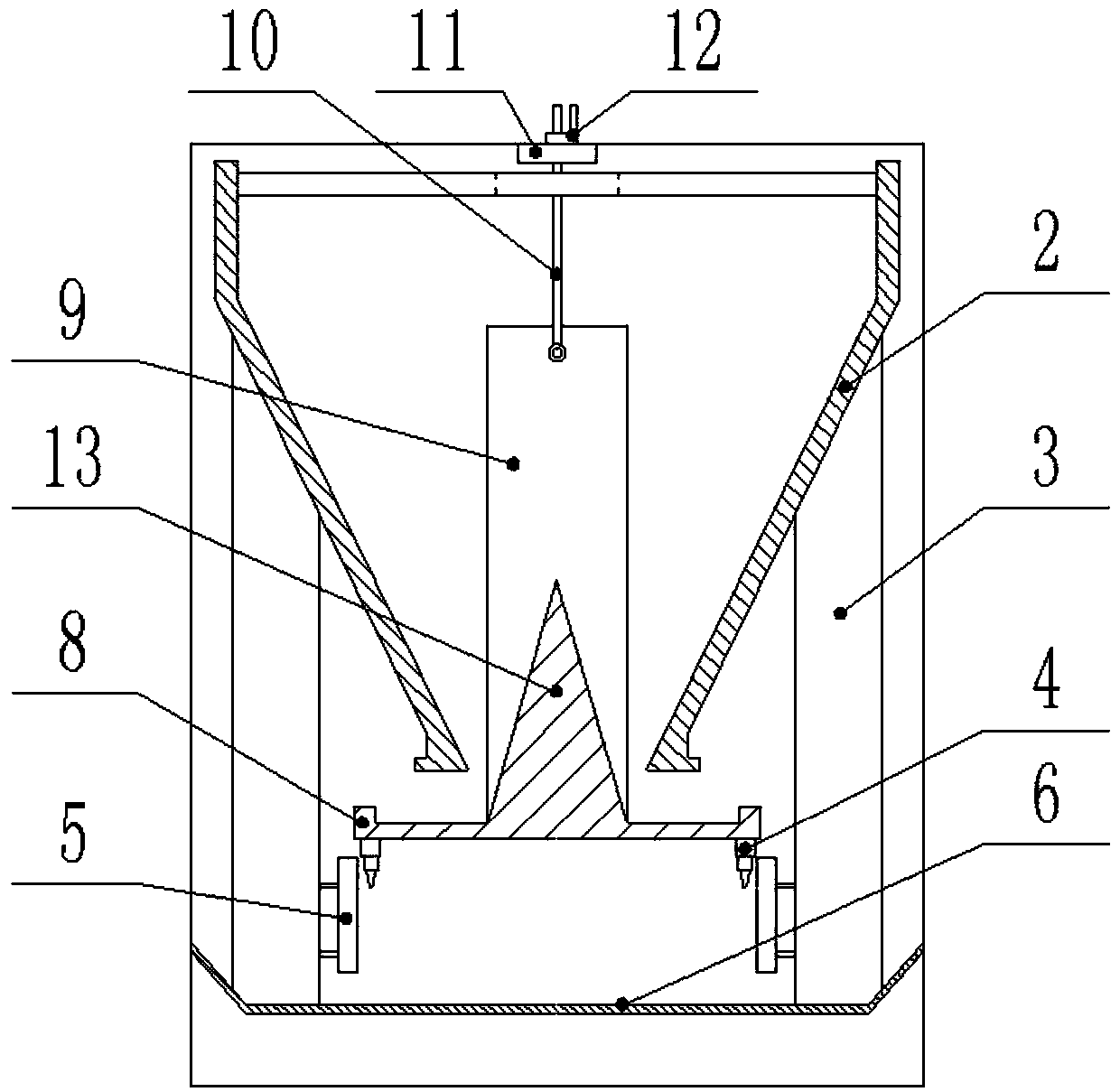

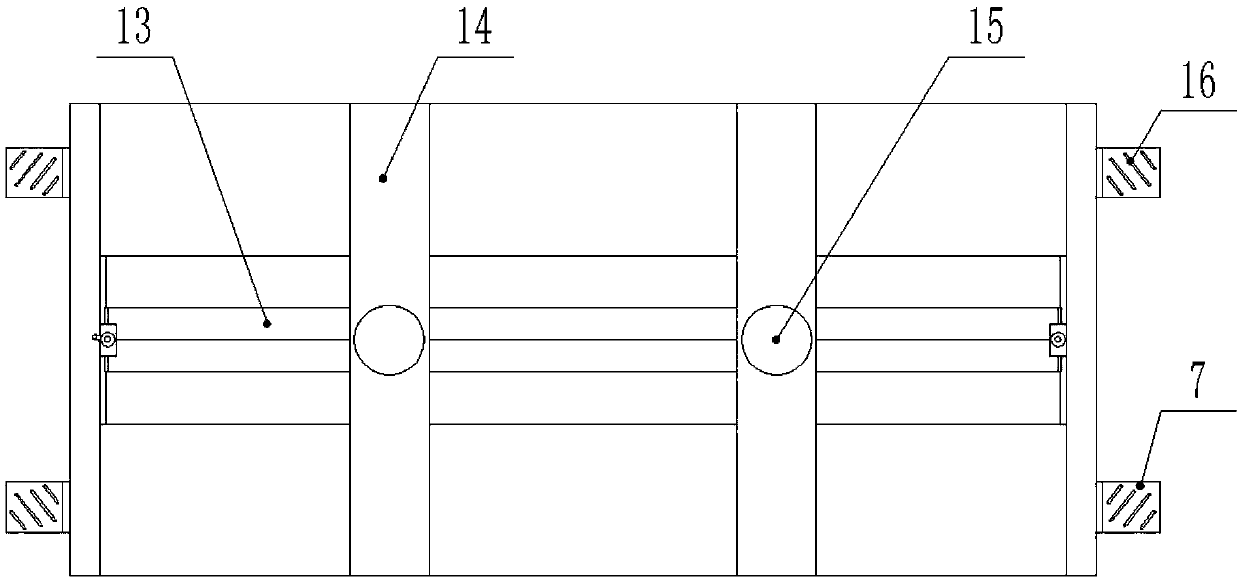

[0014] Such as Figure 1-4 As shown, a double-sided automatic feeding device has a bracket 1, a feeding bin 2 and a feeding tank 8, the feeding bin 2 is arranged on the upper part of the bracket 1, and the feeding tank 8 is arranged below the feeding bin 2. Bracket 1 is composed of two rectangular vertical plates parallel to each other, two side plates parallel to each other and perpendicular to the two rectangular vertical plates are arranged between the two rectangular vertical plates, two rectangular vertical plates and two side plates Surrounded by a feeding bin 2, the feeding bin 2 is in the shape of a funnel with a large top and a small bottom, and the bottom of the feeding bin 2 has a rectangular opening.

[0015] Feed trough 8 is respectively fixed with the connecting plate 9 that size is less than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com