Main engine cabin cover of pesticide sprayer

A technology for spraying pesticides and canopy covers, which can be used in aircraft parts, devices for capturing or killing insects, and building fasteners, etc., which can solve problems such as increased operation difficulty, loose main engine canopy cover, and difficulty in processing and manufacturing. Low production cost, easy to manufacture and assemble, and easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

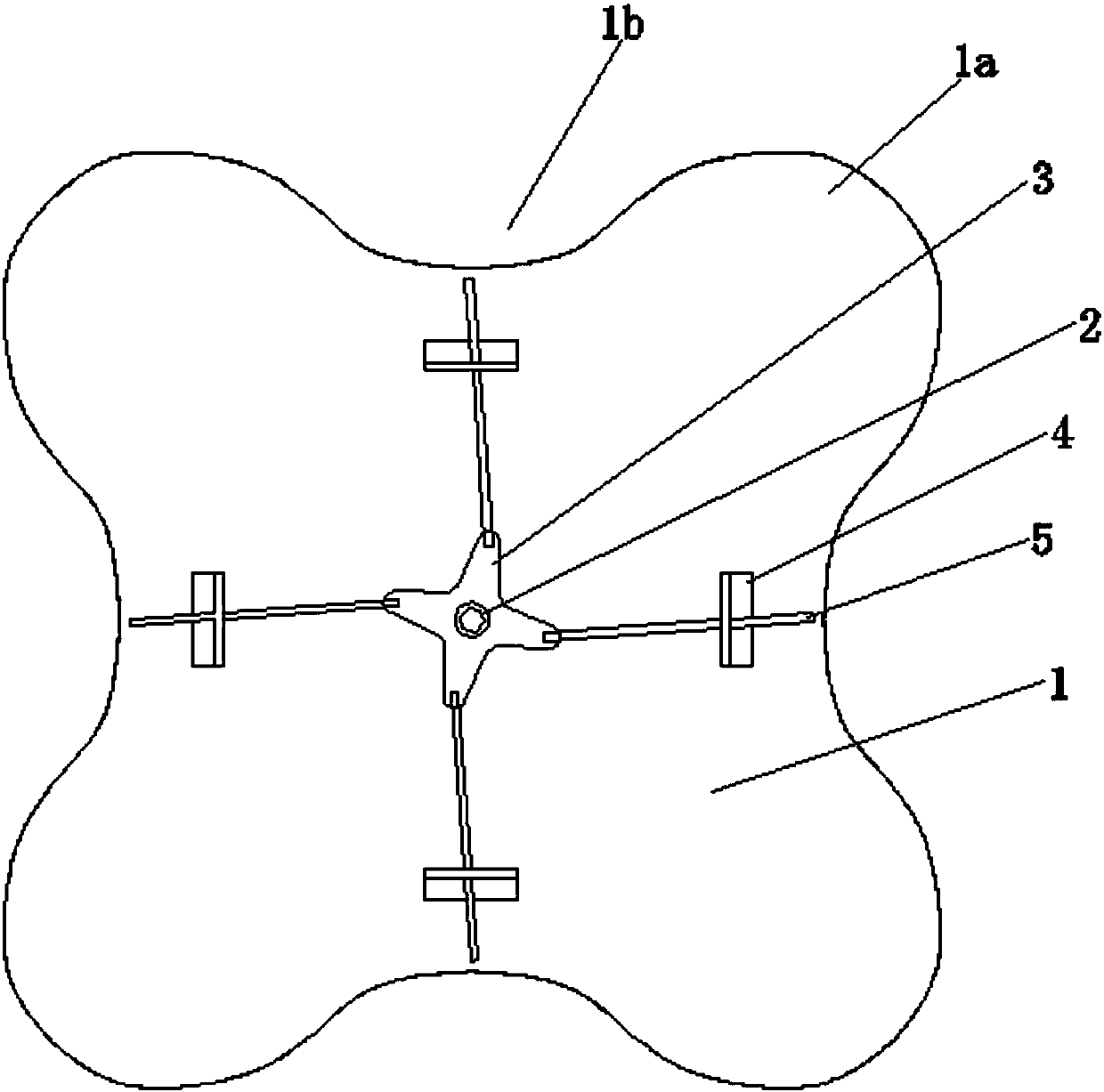

[0015] Such as figure 1 As shown, the main cabin cover of the pesticide spraying machine has a cover body 1, and the cover body 1 is a spherical structure with a high center and a low edge. The outer edge of the cover body 1 is integrally formed with four flanges 1a uniformly distributed on the circumference. The flanges 1a are arc-shaped, and there is a smooth transition between two adjacent flanges 1a through depressions 1b. A lock is embedded in the center of the cover 1 , and the lock core 2 of the lock exceeds the bottom surface of the middle part of the cover 1 downward. The lower end of the lock core 2 is provided with a follower block 3, which is in the shape of a "ten" and is stamped from stainless steel. The follower block 3 is sleeved on the lower end of the lock core 2 and locked by a nut.

[0016] Such as figure 1 As shown, the four free ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com