Manual tool and method for tab flattening of flexibly-packaged power batteries

A power battery and tab technology, which is applied in the field of manual tooling for soft pack power battery tab flattening, can solve problems such as poor tab flattening consistency, poor tab contact, poor welding, etc., to improve welding efficiency, The effect of light weight and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

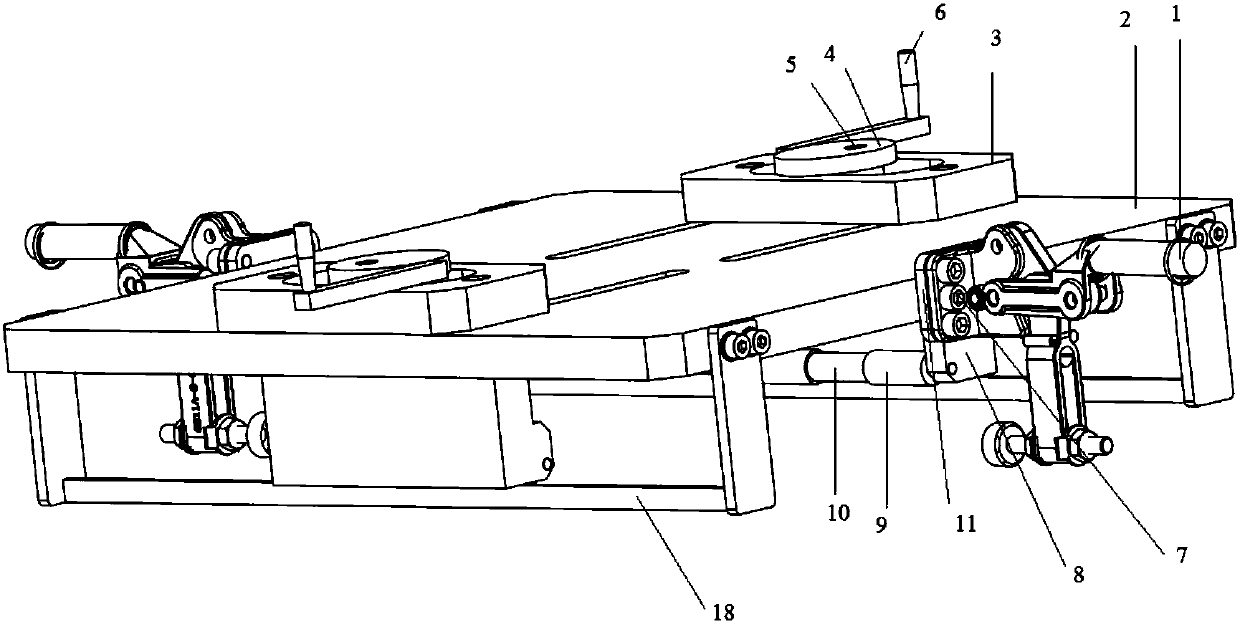

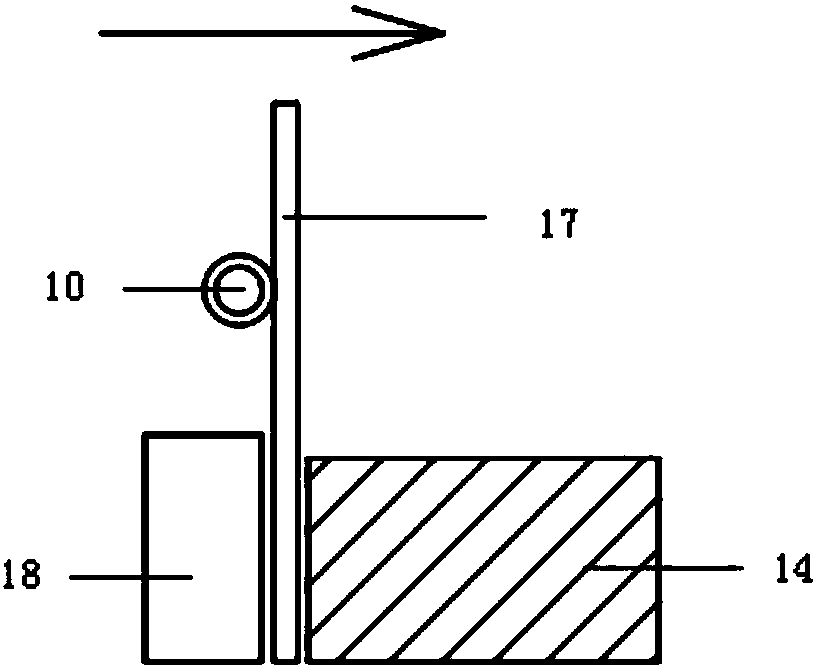

[0032] In this embodiment, the size specification of the power battery 16 is 500mm×178mm×255mm, the height of the battery tab 17 is 25mm, and the width is 45mm.

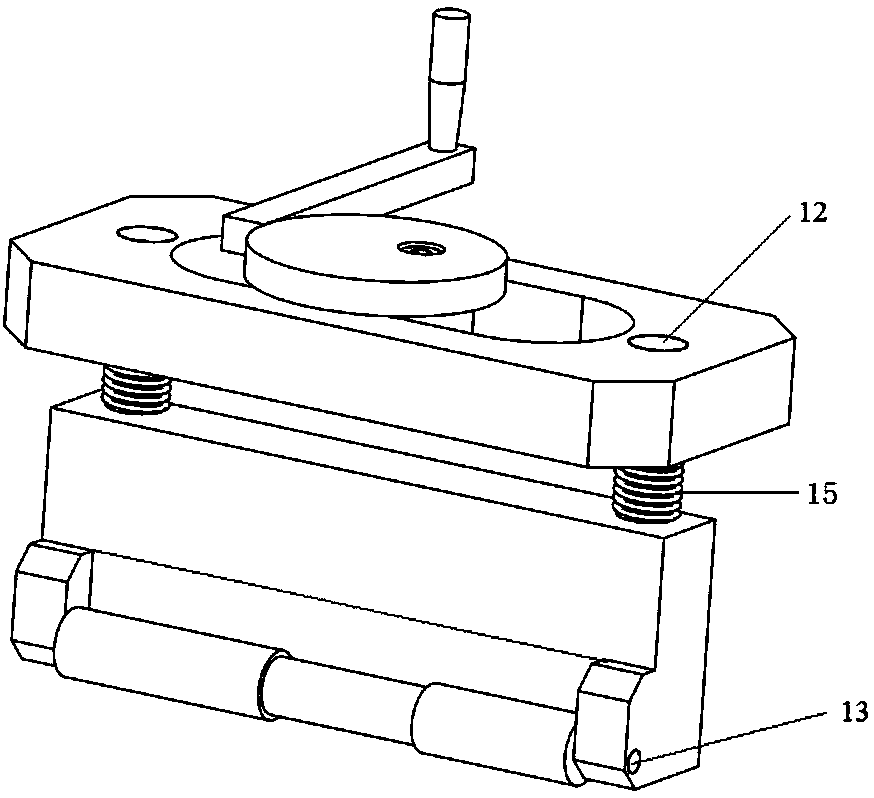

[0033]When working, turn the handle of the elbow clamp first, clamp the power battery with the elbow clamp 1, and fix the whole device on the power battery 16; then turn the handle 6 on the cam 4, and the eccentric mechanism will drive the flattening mechanism below it to move, Usually, the pressure can be set in advance. If the pressure is too high, the pressure spring 15 will be triggered to drive the push plate and other flattening mechanisms to spring up to prevent the tab 17 from being crushed. The push plate 8 is equipped with a bearing 13, and the pressure roller 10 for flattening the lug 17 is installed on the bearing 13. The movement of the push plate 8 drives the pressure roller 10 to move together, and the gap between the two pressure rollers 10 is adjusted according to the difference of the battery module....

Embodiment 2

[0035] In this embodiment, the size specification of the power battery 16 is 700mm×190mm×250mm, the height of the battery tab is 25mm, and the width is 45mm.

[0036] Working principle is the same as embodiment 1. The stroke of the push plate 8 is 70 mm, and the distance between the two tabs 17 is 60 mm. The two push plates 8 can work together to flatten two tabs 17 at one time; the diameter of the pressure roller 10 is 10 mm, and the insulation treatment part 9 The diameter is 8mm, the length is 120mm, and the diameter series of the pressure roller 10 also includes 12mm, 14mm, 8.5mm and so on.

[0037] The invention is simple in structure, easy to operate, can be operated by a single person, and has reliable flattening function; the size of the eccentric mechanism and the bottom plate 2 can be adjusted according to the model of the battery module, so as to realize the flattening of battery lugs of various specifications The present invention can also be used in series to fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com