Method for repairing connecting piece

A connecting piece and hinged technology, which is applied to metal processing machinery parts, clamping, supporting, etc., can solve the problems of increasing labor intensity of workers, taking away bolts, and failure to complete bolt maintenance operations smoothly, so as to reduce labor intensity and improve efficiency , to avoid the effect of shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

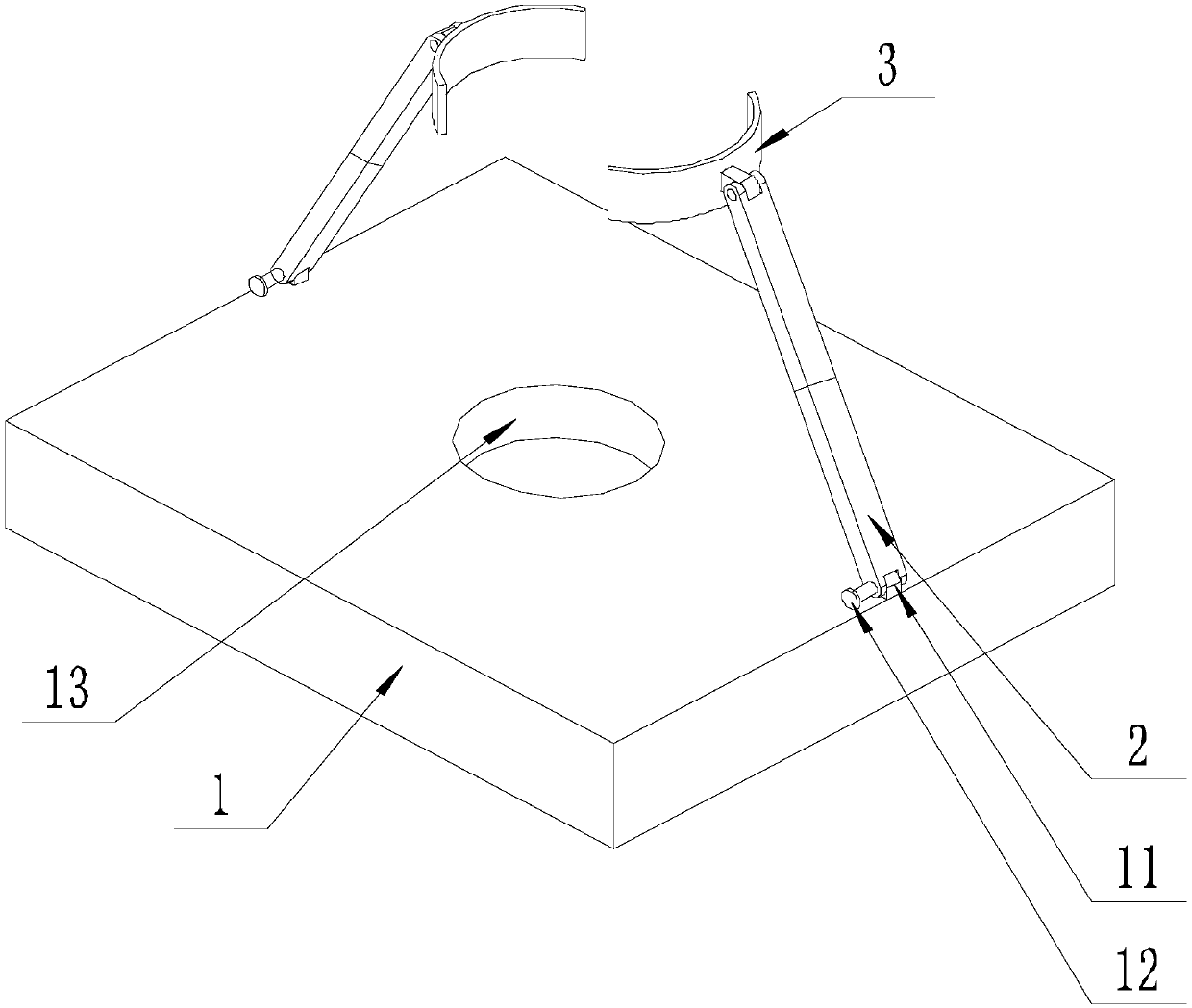

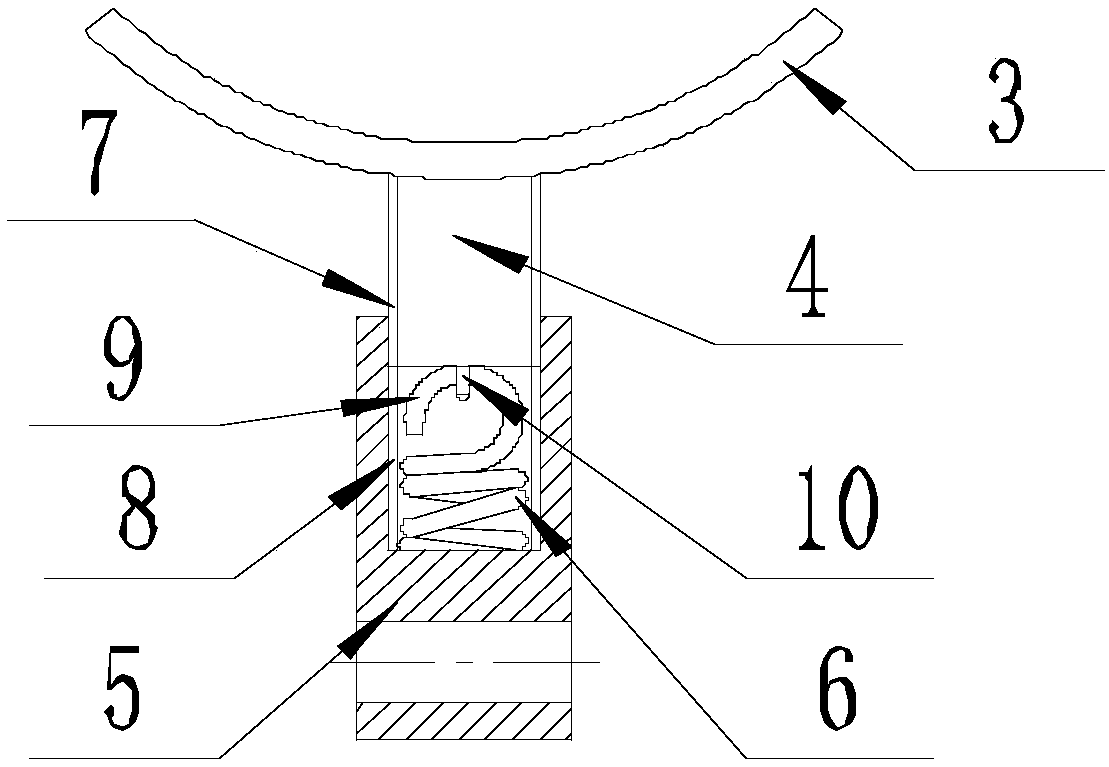

[0040] like Figure 1-Figure 4 As shown, a method for maintaining a connector of the present invention includes the following steps:

[0041] Step A: place the bolt to be repaired between the limit components, make the axis of the bolt perpendicular to the mounting plate 1, and make the head of the bolt contact the mounting plate 1;

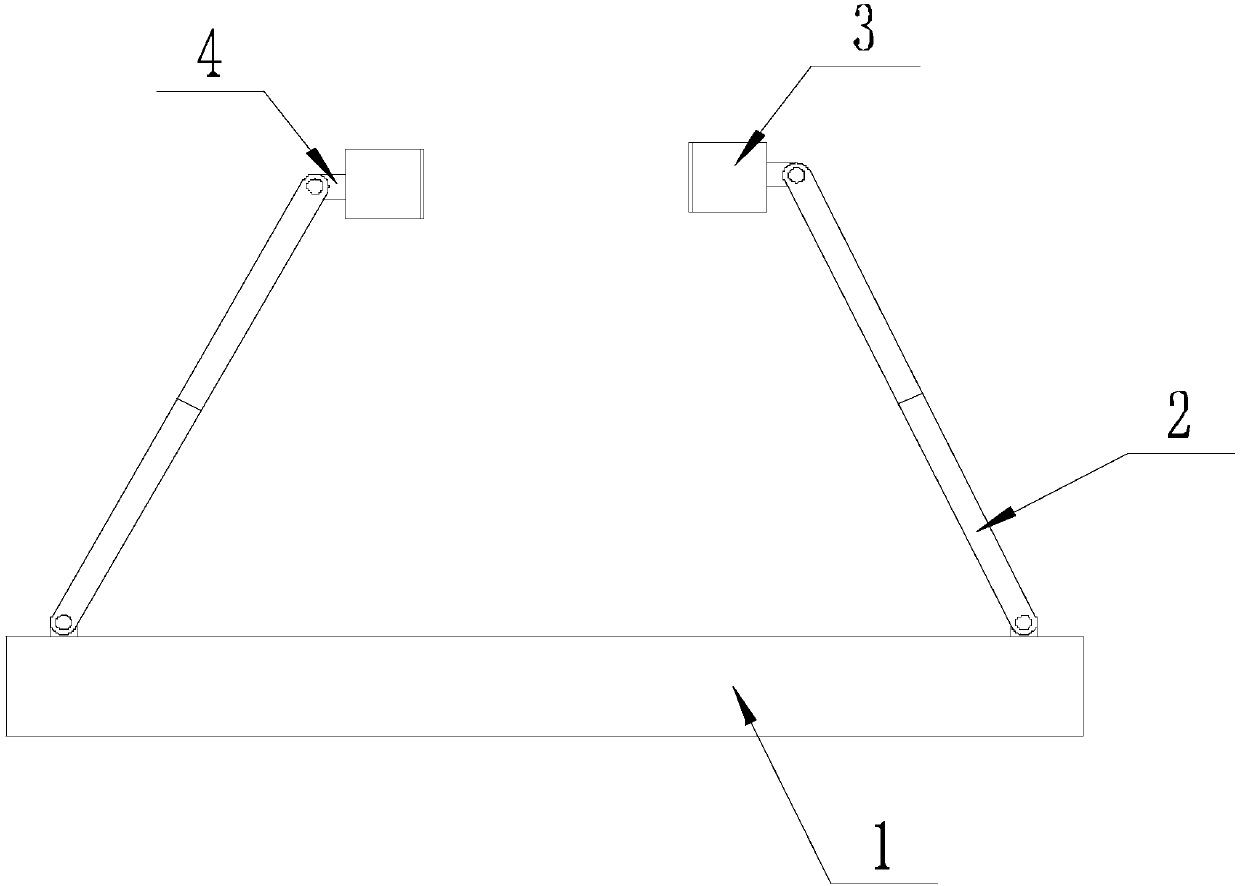

[0042] Step B: Rotate the support arm 2 in the limit assembly so that the limit plates 3 are close to each other;

[0043] Step C: Rotate the limit plate 3 so that the surface of the limit plate 3 away from the support arm 2 is perpendicular to the upper surface of the installation plate 1 and contacts the side wall of the bolt until the limit plate 3 limits the movement of the bolt ;

[0044]Step D: Then use a planer tool to remove the damaged thread at the end of the bolt's shank.

[0045] Through this method, not only the labor intensity of the workers is reduced, but also the situation that the bolts cannot be successfully completed due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com