Preparation method of L-shaped PVC rubber

A technology of L-shaped rubber, applied in the field of preparation of L-shaped PVC rubber, which can solve the problems of calendering production, product elongation, and unstable peel strength, etc., and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

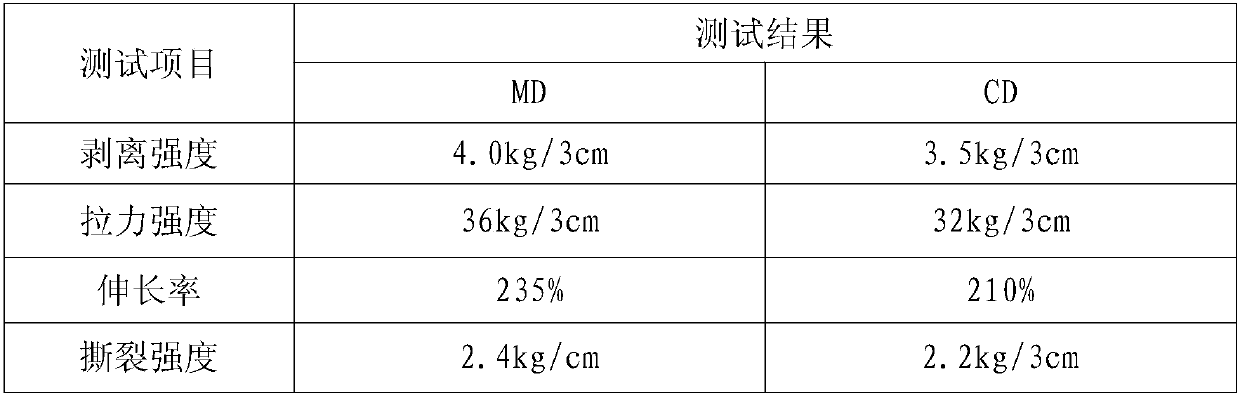

Examples

specific Embodiment 1

[0020] A kind of preparation method of L-type PVC rubber, described L-type PVC production process, comprises the following steps: (1) the production of L-type PVC rubber semi-finished base material; (2) the production of L-type PVC rubber semi-finished fabric; (3) Laminating and embossing integral molding; (4) Surface treatment step;

[0021] The specific operation is as follows:

[0022] (1) described L-type PVC rubber semi-finished product bottom material production step comprises following operation successively:

[0023] a. Mix polyvinyl chloride resin, calcium carbonate, diisononyl citrate, stabilizer, modifier, colorant, etc. through a mixer at high and low speeds, and the material temperature is 100-140°C;

[0024] b. Pass the mixed material through a 10,000-horsepower machine to make it further plasticized, and use a four-roller calender to calender the material at a calendering temperature of 150-210°C, and then undergo embossing, cooling and coiling to obtain a PVC ...

specific Embodiment 2

[0032] A kind of preparation method of L-type PVC rubber, described L-type PVC production process, comprises the following steps: (1) the production of L-type PVC rubber semi-finished base material; (2) the production of L-type PVC rubber semi-finished fabric; (3) Laminating and embossing integral molding; (4) Surface treatment step;

[0033] The specific operation is as follows:

[0034] (1) described L-type PVC rubber semi-finished product bottom material production step comprises following operation successively:

[0035] a. Mix polyvinyl chloride resin, calcium carbonate, diisononyl citrate, stabilizer, modifier, colorant, etc. through a mixer at high and low speeds, and the material temperature is 100-140°C;

[0036] b. Pass the mixed material through a 10,000-horsepower machine to make it further plasticized, and use a four-roller calender to calender the material at a calendering temperature of 150-210°C, and then undergo embossing, cooling and coiling to obtain a PVC ...

specific Embodiment 3

[0044] A kind of preparation method of L-type PVC rubber, described L-type PVC production process, comprises the following steps: (1) the production of L-type PVC rubber semi-finished base material; (2) the production of L-type PVC rubber semi-finished fabric; (3) Laminating and embossing integral molding; (4) Surface treatment step;

[0045] The specific operation is as follows:

[0046] (1) described L-type PVC rubber semi-finished product bottom material production step comprises following operation successively:

[0047] a. Mix polyvinyl chloride resin, calcium carbonate, diisononyl citrate, stabilizer, modifier, colorant, etc. through a mixer at high and low speeds, and the material temperature is 100-140°C;

[0048] b. Pass the mixed material through a 10,000-horsepower machine to make it further plasticized, and use a four-roller calender to calender the material at a calendering temperature of 210°C, and then undergo embossing, cooling and coiling to obtain a PVC semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com