Bill transport mechanism of highway toll station sentry box

A technology of high-speed toll station and conveying mechanism, applied in the direction of conveyor, conveyor object, object supply, etc., can solve the problem of long distance between toll booth and toll vehicle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

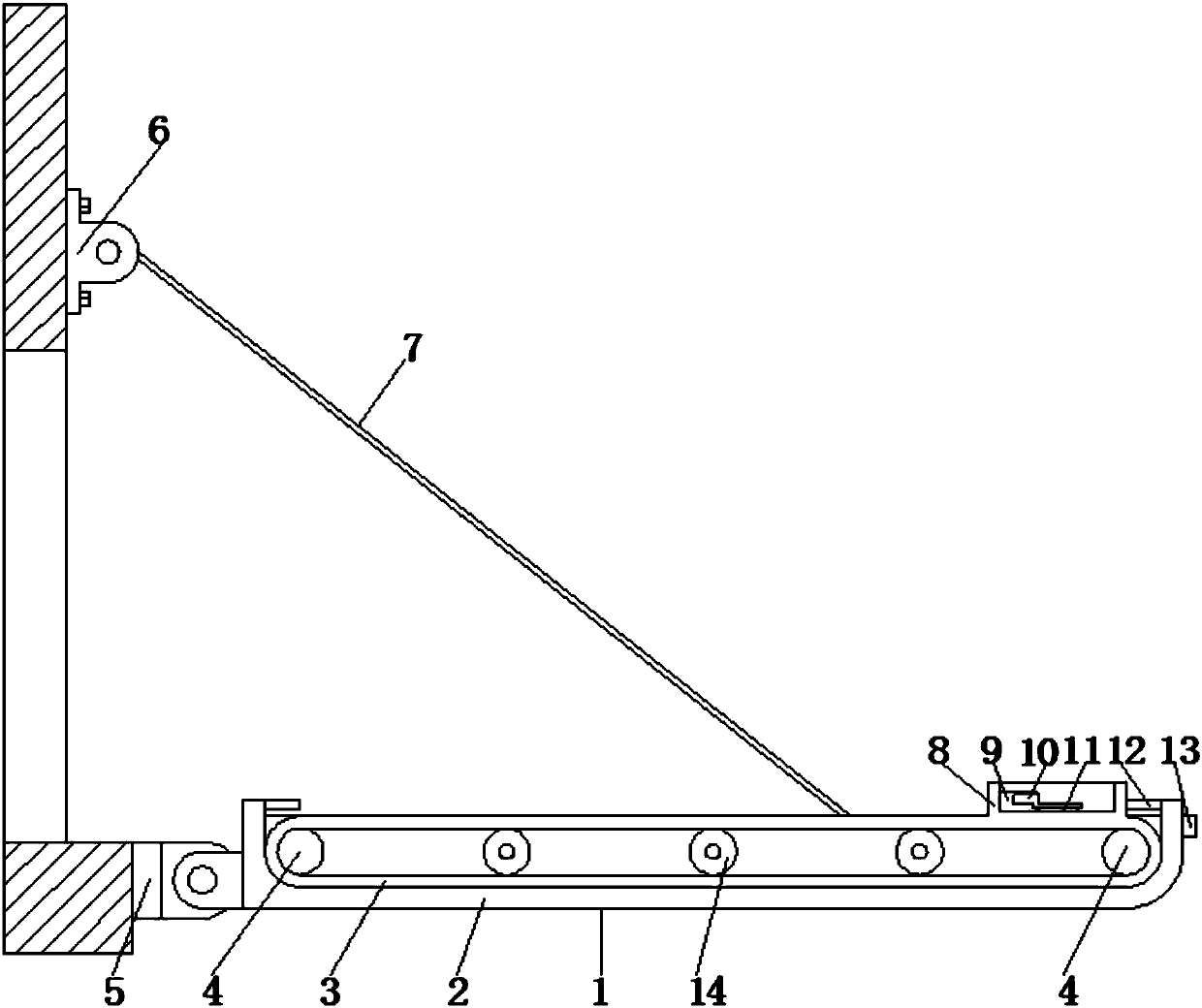

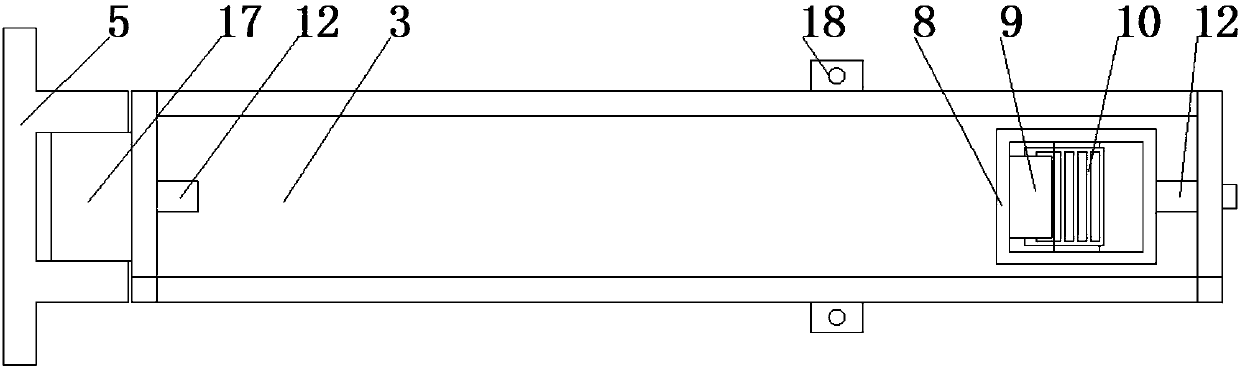

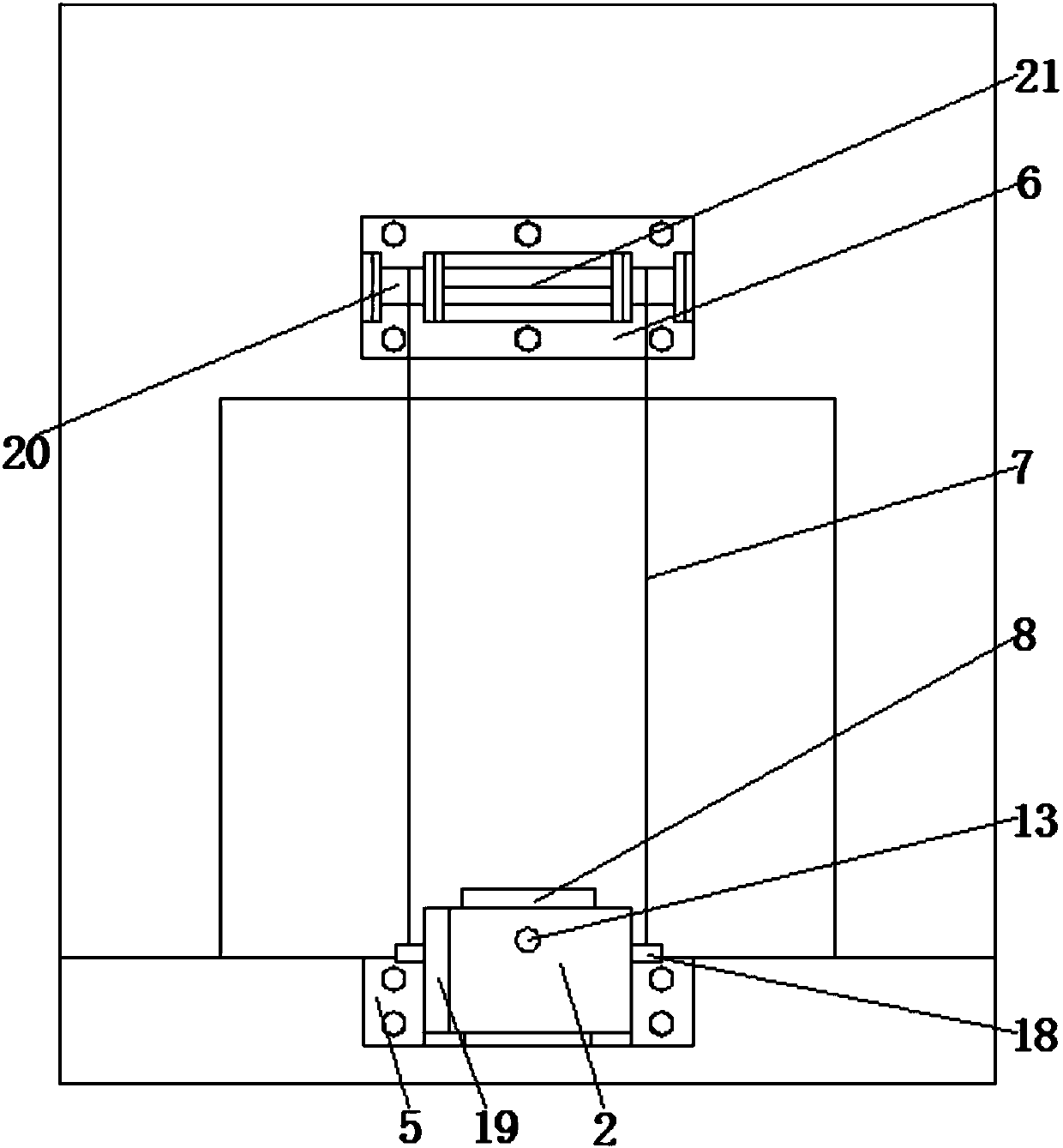

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The invention provides a ticket transmission mechanism for a sentry box at a high-speed toll station, which includes a device body 1, a rotating cantilever 2, a conveyor belt 3, a transmission motor 4, a rotary base 5, a lifting base 6, a steel wire rope 7, an item placement cylinder 8, a clamping Block 9, clamping plate 10, rubber pad 11, limit switch 12, driver operation switch 13, support cylindrical roller 14, bearing 15, transmission motor spindle 16, rotation mounting block 17, wire rope mounting block 18, side baffle 19 , a winding roller 20, a lifting motor 21 and a fixed inner cavity 22, the bottom of the device body 1 is provided with a rotating cantilever 2, and the top of the rotating cantilever 2 is provided with a fixed inner cavity 22; Stroke switch 12, and the top center of the right end of the rotating cantilever 2 is equipped with a driver's operation switch 13 through a screw; the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com