Wheelchair assistance system for crossing overpasses

An auxiliary system and overpass technology, applied to elevators, transportation and packaging in buildings, etc., can solve problems such as high energy consumption, inability to install devices, occupation, etc., and achieve high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

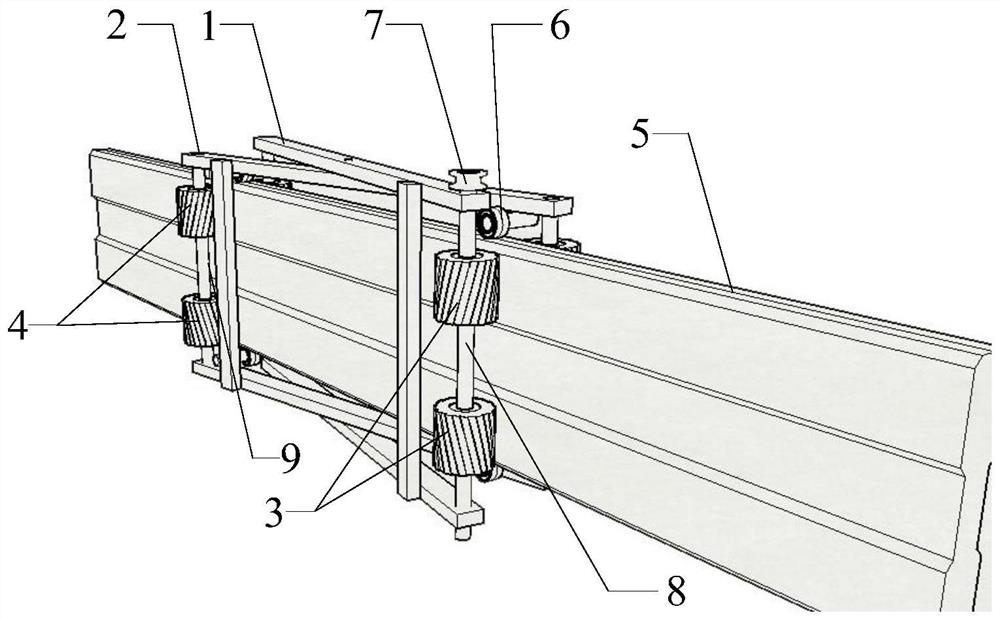

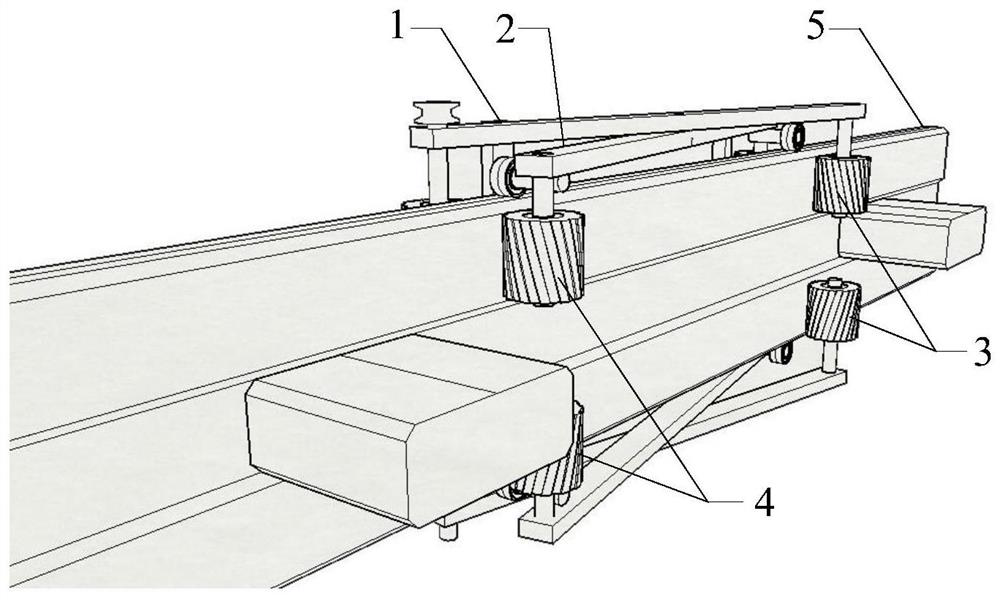

[0041] This embodiment provides a traction device, including a bracket I1 and a bracket II2, the bracket I1 includes two long square steels and a short square steel, the two rectangular steels are arranged parallel to each other and connected by short square steels, It is similar to an I-shaped structure; the bracket II2 includes two long square steels and one short square steel, and the two long square steels are arranged in parallel to each other and connected by short square steels, forming a similar I-shaped structure. The distance between the two rectangular steels of the support II2 is smaller than the distance between the two rectangular steels of the support I1, the support I1 passes through the support II, the two rectangular steels of the support I1 and the two long steel bars of the support II2 The square steel is fixedly connected to each other, and the overall structure is X-shaped. Both ends of the long axis direction of the bracket I1 are provided with two activ...

Embodiment 2

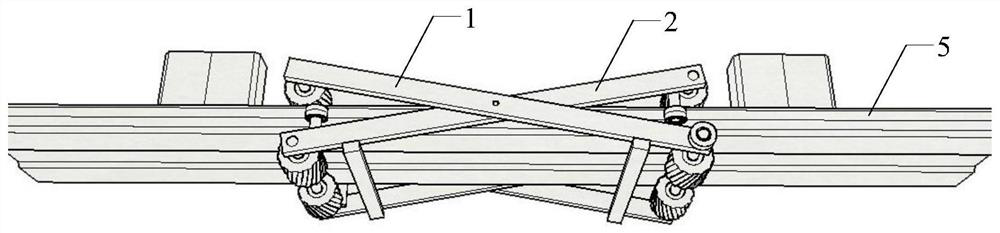

[0043] Further improvement on the basis of Example 1, if the two rectangular steels of bracket I1 are marked as A1 and A2 respectively, and the two rectangular steels of bracket II2 are marked as B1 and B2 respectively, one rectangular steel of bracket I1 The steel A1 is hingedly connected to one rectangular steel B1 of the bracket II2, the other rectangular steel A2 of the bracket I1 is hingedly connected to the other rectangular steel B2 of the bracket II2, and the connecting line of the two hinged connection points is used as the axis, The X-shaped structure takes the axis as the axis to open and close and rotate. The overall structure is X-shaped, similar to the structure of scissors

[0044] The two frames of the bracket I1 and the bracket II2 are connected by a tension spring, specifically, the axial ends of the rectangular steel A1 and the axial ends of the rectangular steel B1 are connected by a tension spring, and the rectangular steel A2 is connected by a tension spr...

Embodiment 3

[0046] Further improvement on the basis of Embodiment 2, guide wheels 6 are provided at both axial ends of the bracket I1 and the bracket II2, and the guide wheels 6 are used for walking on the upper and lower end surfaces of the guide rail 5 . Sprocket 7 is arranged on the shaft section of the active friction wheel 3 at both ends of the long axis direction of the frame I1, which is connected with the sprockets at both ends of the frame I1 by the same chain, and the motor drives the sprocket to rotate, thereby driving the frame. All the driving friction wheels 3 at both ends of the long axis direction of I1 rotate synchronously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com