Binning method of rising and falling binning trolleys

A technology of trolleys and containers, applied in lifting devices, loading/unloading, transportation and packaging, etc., can solve problems such as low efficiency, inconvenient operation, complex structure, etc., and achieve the effect of strong bearing capacity, simple structure and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

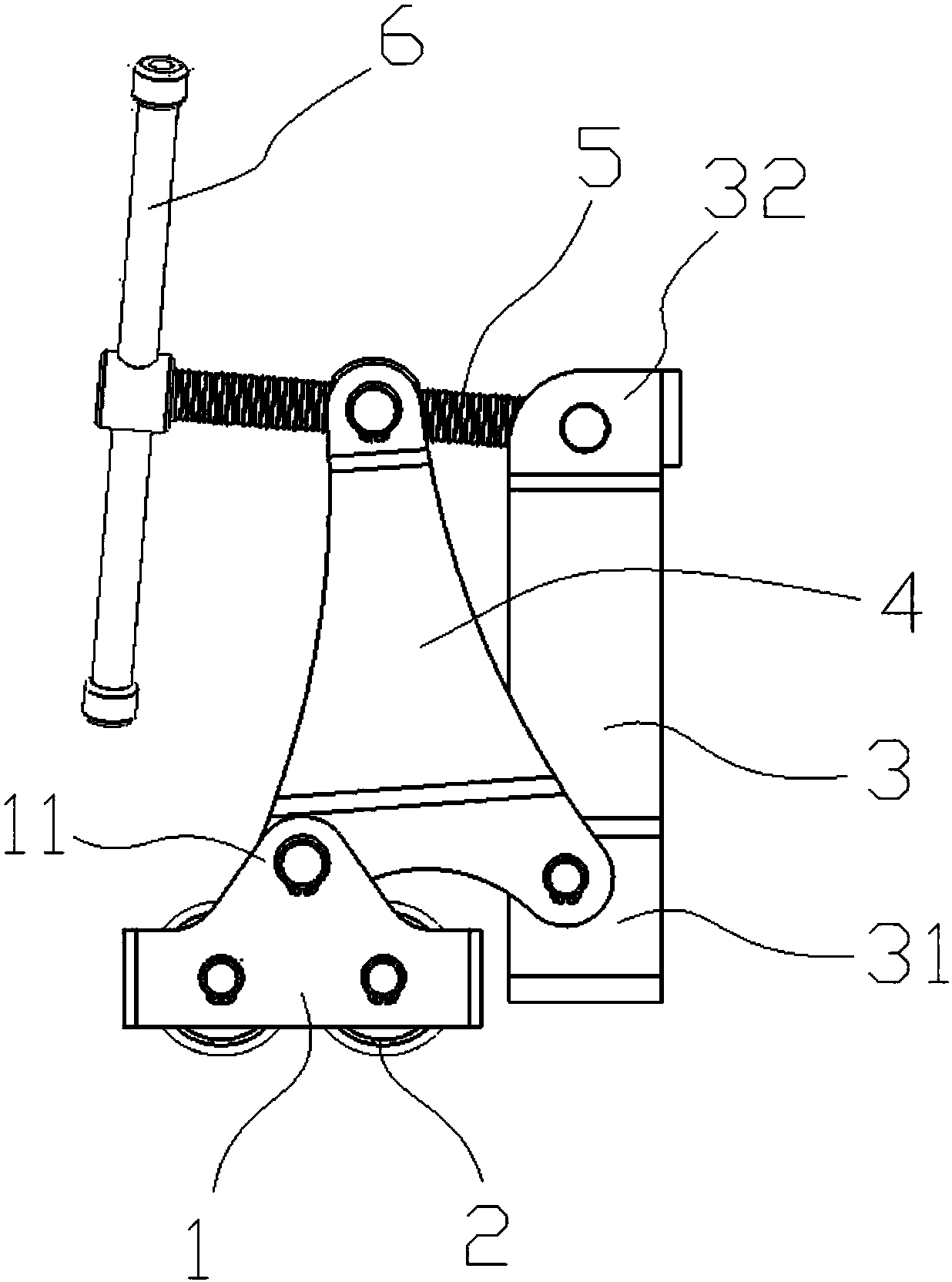

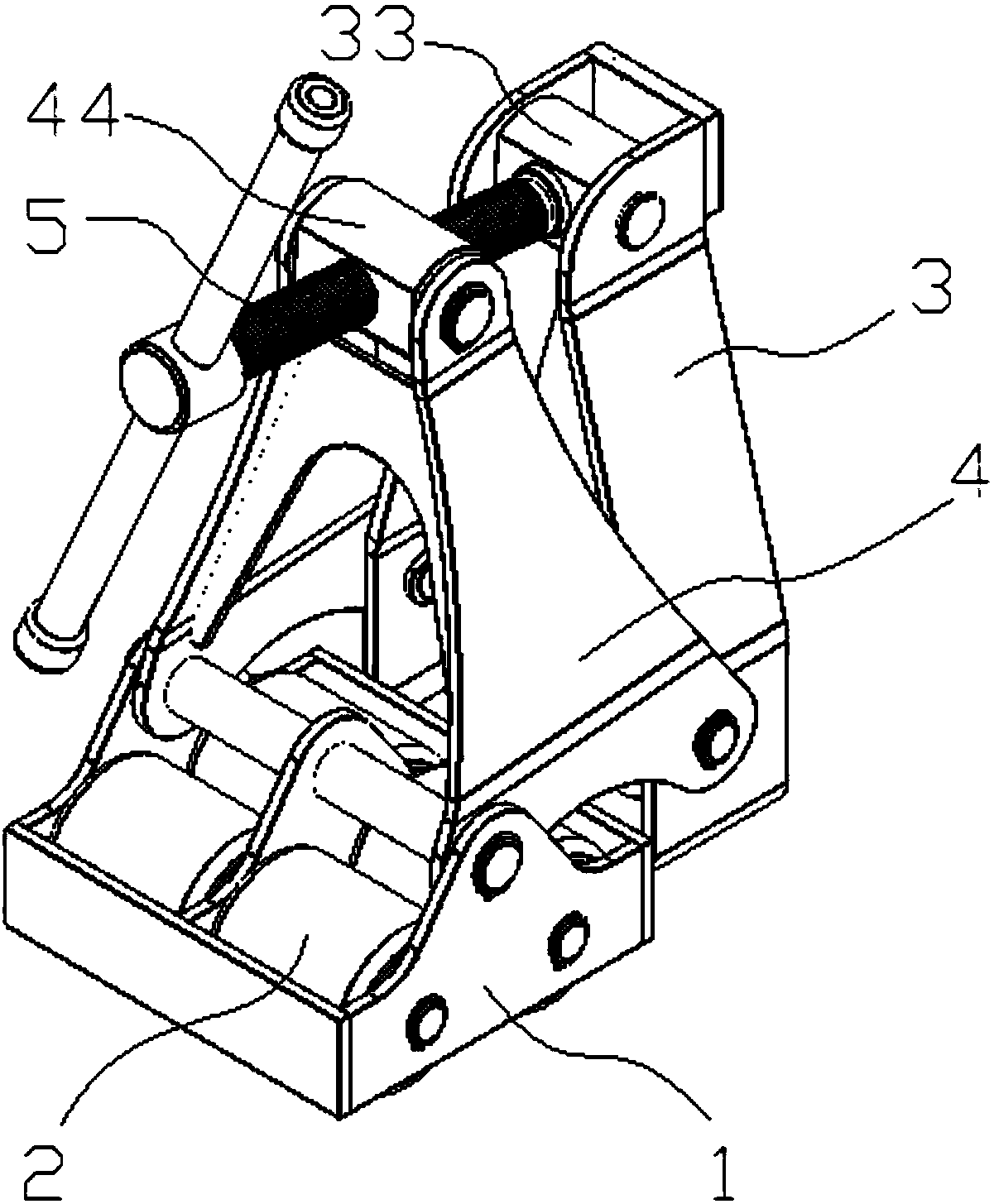

[0050] Such as figure 1 Shown, a kind of lifting and lowering packing trolley comprises roller frame 1, roller 2, support 3, lever frame 4 and screw mandrel 5, as image 3 and Figure 5 As shown, the roller frame 1 is composed of three partitions and a partition frame; the rollers 2 are connected and arranged on the roller frame 1 through pin shafts, two rollers 2 are arranged in parallel between each of the three partitions, and the rollers 2 are arranged inside Deep groove ball bearings enable the rollers to rotate and roll more flexibly; figure 1 and Figure 5 As shown, a support portion 11 is provided on the top of the upper partition on the roller frame 1;

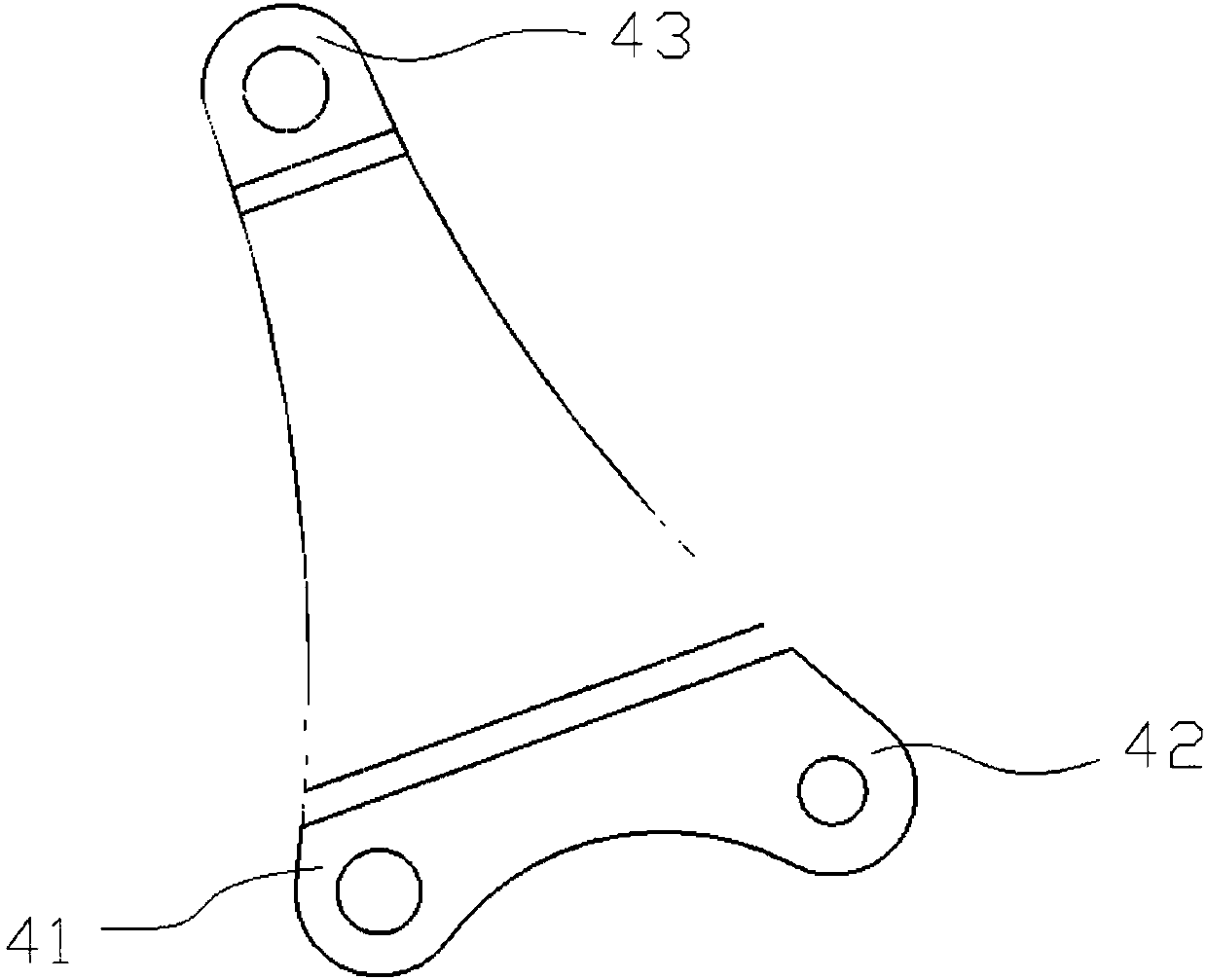

[0051] Such as figure 2 and Figure 4 As shown, the lever frame 4 includes a fulcrum portion 41, a resistance portion 42 and a power portion 43. On the same plane, the distance between the support portion 11 and the fulcrum portion 41 connecting the axis of the pin shaft to the resistance portion 42 connecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com