Pre-tightening device of coupled thrust ball bearings

A thrust ball bearing, paired technology, applied in the direction of bearings, flexible bearings, bearing components, etc., can solve the problems of complex structure, troublesome adjustment, difficult automatic compensation, etc., and achieve the effect of large contact area and uniform elastic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, the specific implementation, structure, Features and their functions are described in detail below.

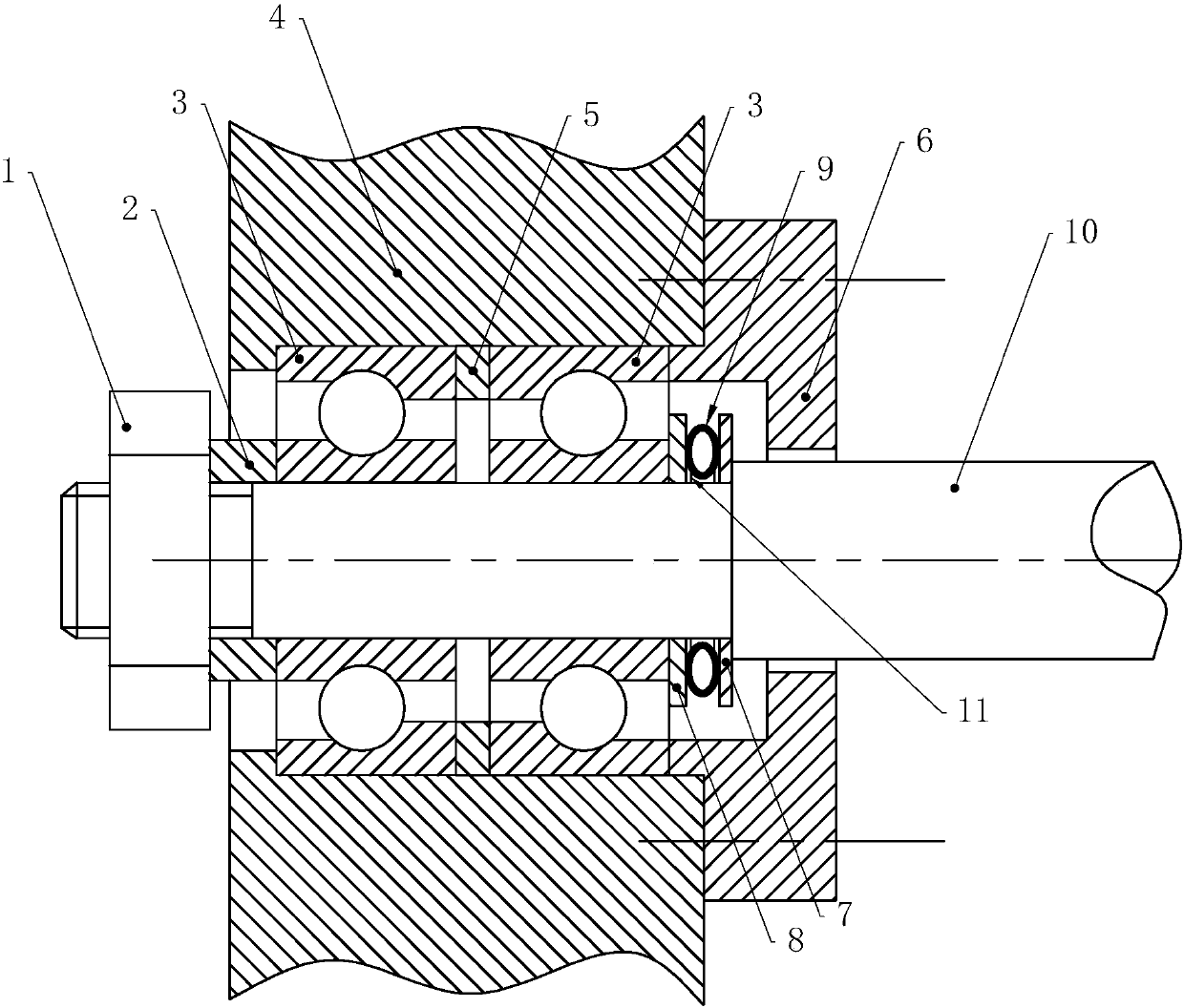

[0024] see figure 1 , a pair of thrust ball bearing preloading devices, including a nut 1, an annular inclined section spring 9, two clamping plates, two thrust ball bearings 3 back-to-back sets on the transmission shaft 10, the outer rings of the two thrust ball bearings 3 Both are supported on the bearing seat 4; the inner rings of the two thrust ball bearings 3 are fixed by the nut 1 and the first bushing 2, and the first bushing 2 is clamped between the nut 1 and the thrust ball bearing 3 near the end of the transmission shaft 10 Between the inner rings of the drive shaft 10, the nut 1 is installed on the end of the transmission shaft 10 and pressed against the first sleeve 2, which can move axially through rotation; the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com